Last month, YG Machinery successfully exported a thread rolling machine for sale to a customer in Guatemala. The machine was delivered on time, and the client has already installed it in his factory. After using the equipment for a few days, he praised its smooth performance and production efficiency. He was especially impressed by the low failure rate and improved output stability.

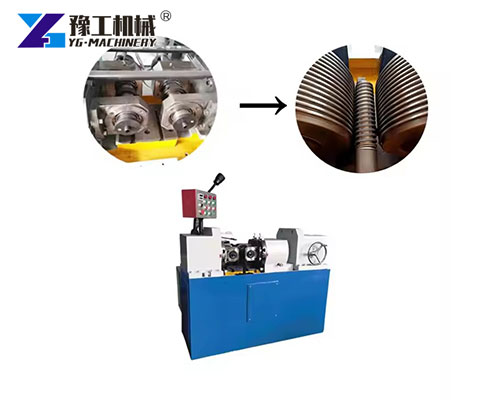

The thread rolling machine for sale from YG is designed to create strong and uniform threads on cylindrical components such as bolts, studs, and bearings. Instead of cutting into the metal, the thread is formed by pressing dies against the rotating material. This cold forming method enhances thread strength and ensures a cleaner finish. Our machines are known for their:

- High threading accuracy

- Long service life

- Simple operation

- Energy efficiency

WhatsApp/WeChat/Phone: 86 138 3715 9132

Customer Background And Purchase Decision

The customer is the owner of a mechanical processing plant in Guatemala. His workshop handles the production of bearing components that require accurate threading. Previously, he used a locally sourced machine that suffered frequent breakdowns, leading to production delays and high maintenance costs.

Frustrated by the inefficiency, he searched for a better solution using the term “thread rolling machine” on Google. He found YG Machinery and contacted our team. After discussing technical specifications and watching a virtual factory tour, he was confident in our product quality and placed an order immediately.

Product Features And Performance Advantages

The machine delivered to the Guatemalan customer includes the following features:

- Hydraulic Drive System: Provides steady force with adjustable pressure.

- High-Precision Dies: Heat-treated for durability and consistent performance.

- Heavy-Duty Structure: Ensures vibration-free threading even at high speed.

- Low Maintenance Design: Fewer moving parts and longer intervals between servicing.

- Safety Mechanisms: Equipped with overload protection to prevent damage.

These features ensure efficient threading of high-volume parts with minimum downtime.

Advantages of Hydraulic Threading Machines

Hydraulic threading machines excel in thread manufacturing with superior performance:

- Consistent Force – Delivers smooth, controllable power for uniform threads, even in tough materials.

- Stability & Precision – Hydraulic dampening minimizes vibration, ensuring high accuracy and longer die life.

- Overload Protection – Built-in pressure relief prevents damage from excessive force, reducing repair costs.

- Precise Control – Adjustable speed and pressure optimize thread quality for varied materials and specs.

- Versatility – Handles diverse thread types, pitches, and materials efficiently.

- Low Maintenance – Fewer mechanical parts mean less wear and reduced downtime.

Ideal for high-quality, high-efficiency threading in automotive, construction, and machinery industries.

Specific Use Cases for Thread Rolling Machines

YG Machinery’s thread rolling machine serves various industries successfully, including:

- Automotive Bolt Production (Argentina)

- A factory used our machine to increase the threading capacity for suspension bolts. Production speed rose by 30%.

- Construction Fasteners (Peru)

- Our client needed robust threads for concrete anchors. The machine handled large-volume output with ease.

- Steel Pipe Accessories (Colombia)

- Threaded couplers for oil pipes require precision and durability. YG’s machine met all project requirements.

- Bearing Housings (Guatemala)

- The customer mentioned above reported better thread uniformity and 20% less machine downtime after upgrading to YG’s solution.

How To Choose The Right Thread Rolling Machine

Choosing the right machine depends on your specific application. Key factors to consider include:

- Thread Size Range: Select a model that fits your common workpiece diameters.

- Production Volume: High-speed or CNC models are better for mass production.

- Material Type: Ensure compatibility with the metals you process.

- Available Space: Consider machine size and installation needs.

- Operation Mode: Decide between manual, semi-automatic, and fully automatic machines.

Consulting with a trusted supplier like YG Machinery can help you make the best choice based on technical needs and budget.

Factors Affecting Roll Thread Machine Price

- Machine Type: Manual machines are cheaper, while hydraulic threading machines and CNC models cost more.

- Threading Capacity: Larger machines for big-diameter threads have higher prices.

- Tooling & Dies: Custom dies or carbide tooling add to the cost.

- Automation Level: Features like PLC control or automatic feeding raise the price.

- Manufacturer Support: Brands that offer strong after-sales service may charge slightly more but ensure long-term value.

YG Machinery provides competitive pricing without compromising on quality. Each machine is backed by technical support and spare parts supply.

WhatsApp/WeChat/Phone: 86 138 3715 9132