What Is a Dry Ice Blaster?

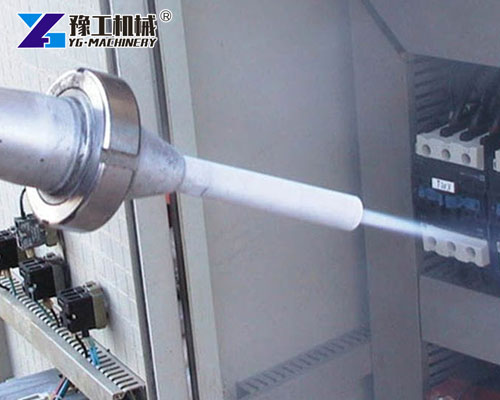

A dry ice blaster is an advanced cleaning device that uses compressed air to accelerate dry ice pellets (solid CO₂) at high speeds to clean surfaces. Unlike traditional cleaning methods that rely on water, solvents, or abrasives, CO2 blasting equipment is non-abrasive, non-toxic, and leaves no secondary waste.

When dry ice hits the dirty surface, it sublimates instantly—turning from solid to gas—removing contaminants without damaging the substrate. This makes it ideal for delicate or sensitive equipment and high-precision environments.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of Dry Ice Blaster for Sale

| Model | ICE-JET 3.0 | ICE-JET 6.0 | ICE-JET 15 | ICE-JET 40 |

| Dry Ice Capacity | 3KG | 6KG | 15KG | 40KG |

| Dry lce Consumption | 20-50KG/H | 20-50KG/H | 30-100KG/H | 30-100KG/H |

| Supply Pressure | 3-10bar | 13-10bar | 3-10bar | 3-10bar |

| Air Consumption | 1-2m³/min | 1-3m³/min | 1-4m³/min | 1-5m³/min |

| Weight | 40KG | 50KG | 65KG | 80KG |

| Dimensions | 460x340x750mm | 460x350x850mm | 550x445x985mm | 650x550x1000mm |

| Total Power | <500W | <800W | <800W | <800W |

Key Features of CO2 Blasting Equipment

Modern dry ice blasters are built with high-quality components and designed for industrial performance. Core features typically include:

- Adjustable Blasting Pressure: Allows for both delicate and aggressive cleaning.

- Variable Pellet Sizes: Choose between micro-particles or larger dry ice chunks for specific applications.

- Non-Conductive: Safe for cleaning electrical and electronic systems.

- No Water or Residue: Perfect for facilities requiring dry cleaning processes.

- Portable and Compact Designs: Easy to transport on job sites or between facilities.

These features make CO2 blasting equipment versatile across various industries.

Advantages of Using a Dry Ice Blaster

Dry ice blasting offers numerous advantages over traditional cleaning methods:

Efficiency

- Cleans without disassembly

- Reduces machine downtime

- Saves labor and water

Surface Preservation

- Non-abrasive method protects tools, electronics, and sensitive surfaces

- No scratching or erosion

Environmental Safety

- No secondary waste to clean up

- CO₂ used is a byproduct of other industrial processes—no added emissions

- No chemical residues left behind

Operator-Friendly

- Minimal PPE required

- Quiet operation (relative to sandblasting)

- Simple setup and use

Industrial Applications of CO2 Blasting

The dry ice blaster for sale is suitable for a wide range of industrial and commercial uses. It is commonly used in:

- Plastic Molding Industry

Removes mold release agents and plastic buildup without damaging the mold cavity. - Food and Beverage Processing

Cleans food-grade conveyors, ovens, and mixing tanks without water or chemicals. - Printing Press Maintenance

Eliminates ink, grease, and paper dust from rollers and gears without dismantling. - Power Generation and Electrical Equipment

Safe for switchgear, turbines, transformers, and circuit boards. - Automotive Manufacturing

Used to clean robotic welders, fixtures, and assembly line tools without halting production.

Choosing the Right Dry Ice Blaster for Sale

When investing in CO2 blasting equipment, consider the following:

- Application Type

Light-duty for electronics vs. heavy-duty for mold or industrial grime. - Air Supply Capacity

Ensure your compressor meets the air consumption requirements of the machine. - Pellet Size Compatibility

Choose smaller pellets for fine cleaning and larger ones for industrial dirt. - Mobility

If moving between worksites, go for a wheeled, portable unit. - Ease of Maintenance

Units with fewer moving parts and accessible controls reduce downtime.

Maintenance and Safety Tips

Operating a dry ice blaster is relatively low-risk but requires a few precautions:

- Proper Ventilation: CO₂ is heavier than air—work in ventilated areas to avoid buildup.

- Protective Gear: Operators should wear gloves and goggles to avoid pellet impact or freeze burns.

- Inspect Hoses and Nozzles: Regularly check for wear and ice build-up.

- Store Dry Ice Safely: In insulated containers away from sunlight and confined spaces.

Routine maintenance ensures optimal performance and long service life.

FAQ – Dry Ice Blaster for Sale

- Q1: Does dry ice blasting leave any residue?

No. Dry ice sublimates completely into gas, leaving no liquid or solid waste. - Q2: Is dry ice blasting safe for electrical equipment?

Yes. It’s non-conductive and dry, making it ideal for motors, switchboards, and control panels. - Q3: Can I rent or must I purchase a dry ice blaster?

Many suppliers offer both rental and purchase options, but long-term users typically find buying more cost-effective. - Q4: How often do I need to refill dry ice?

Refills depend on usage intensity. On average, 20–30 kg of dry ice can support a few hours of operation. - Q5: Is special training required to operate the machine?

Not necessarily. Most units are plug-and-play with basic operator instructions.

WhatsApp/WeChat/Phone: 86 138 3715 9132