The Hand-held Rock Drilling Machine is a portable tool that drills holes into rock or concrete. Workers widely use it in mining, construction, quarrying, and road repair projects. Its compact design allows a single operator to work in tight spaces where large rigs cannot access.

Because it is compact and easy to maneuver, it is ideal for working on hillsides, in tunnels, or in narrow areas.

WhatsApp/WeChat/Phone: 86 138 3715 9132

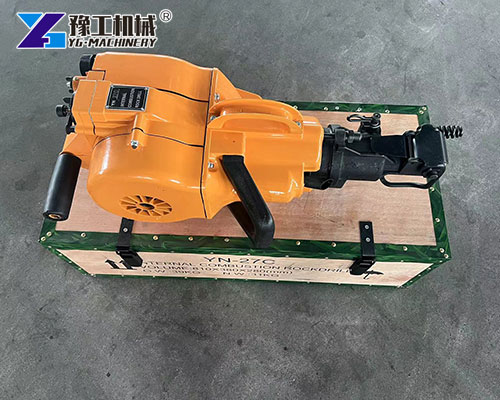

YN27C Rock Drill For Sale Parameters

The YN27C Rock Drill for Sale is one of the most popular models. It is powered by gasoline and does not need air or electricity to operate.

Here are its main specifications:

- Drilling Diameter: 28–42 mm

- Drilling Depth: Up to 6 meters

- Weight: 27 kg

- Engine Type: Single-cylinder, air-cooled, 2-stroke

- Power Output: 1.5 kW at 2450 rpm

- Fuel Consumption: <0.12 L/min

- Function: Can both drill and break rocks

Workers worldwide choose this model for its simplicity, especially in remote construction areas.

Types Of Rock Drilling Machine

There are different types of Rock Drilling machines depending on the power source:

- Pneumatic Rock Drill: Runs with compressed air. Requires an air compressor.

- Gasoline Rock Drill: It has an engine. No need for extra power.

- Electric Rock Drill: Works with electric power. Ideal for indoor jobs.

- Hydraulic Rock Drill: Uses hydraulic pressure. Often seen in large equipment.

Among these, the Gasoline Rock Drill like YN27C is best for portable outdoor drilling.

How Does A Gasoline Rock Drill Work

The Gasoline Rock Drill works simply:

- Ignition: Start the engine using a pull-start.

- Piston Action: The internal piston moves up and down quickly.

- Hammering: The piston hits the drill steel, breaking the rock.

- Rotation: A gear system rotates the drill bit for faster penetration.

- Exhaust: Waste gas is released through side ports.

This process repeats fast—over 2000 times per minute—allowing for efficient drilling.

Gasoline Rock Drill vs Pneumatic Rock Drill

There are a few differences between gasoline and pneumatic drills. Here is a quick comparison:

| Feature | Gasoline Rock Drill | Pneumatic Rock Drill |

|---|---|---|

| Power Source | Gasoline engine | Compressed air |

| Mobility | High | Low |

| Setup Required | None | Air compressor needed |

| Maintenance | More (engine care) | Less |

| Weight | Heavier | Lighter |

| Use Case | Outdoor, remote | Urban, large projects |

If you are working in remote areas, a Hand-held Rock Drilling Machine powered by gasoline is a better choice.

Applications Of Hand-Held Rock Drilling Machines

These machines are widely used in:

- Mining Projects: For small mine tunnels or surface blasting. (Operators frequently combine rock drills with hydraulic rock splitters for sequential drilling and splitting tasks.)

- Road Construction: Breaking hard ground or preparing for explosives.

- Railway Engineering: Rock anchoring or foundation hole drilling.

- Mountain Projects: Drilling in steep slopes where big machines can’t go.

- Disaster Relief: Quick rock breaking after landslides or earthquakes.

Because they don’t rely on external power, they can be used almost anywhere.

Common Questions About Hand-Held Rock Drills

- How deep can a hand-held rock drill go?

Usually up to 6 meters, depending on the material. - Can one person operate it?

Yes, it’s designed for single-person use. - What kind of rocks can it drill?

Hard rocks like granite, limestone, and basalt. - Can I use it to break concrete?

Yes. It can work as a breaker when needed. - Does it work in high altitudes?

Yes, though engine adjustment may be needed. - How to maintain the engine?

Check oil levels, clean the air filter, and inspect the spark plug regularly.

WhatsApp/WeChat/Phone: 86 138 3715 9132