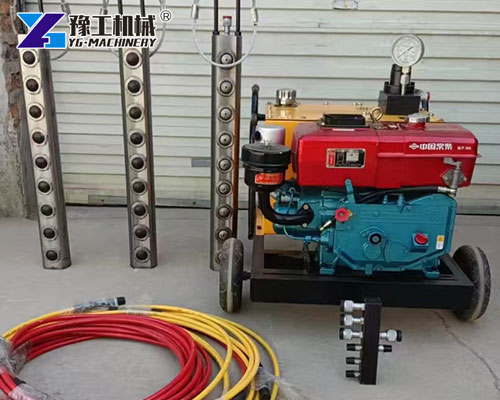

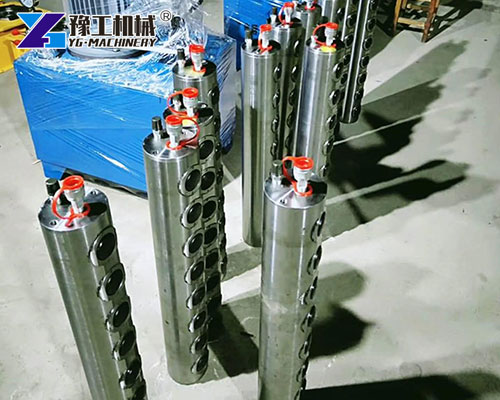

A Hydraulic Splitting Rod is a long, powerful steel tool used in rock breaking and quarrying. It works with a hydraulic station and breaks rock from the inside. It is especially useful in narrow places or deep holes where other machines can’t reach.

This tool can split large rocks without noise, dust, or vibration. Quarrying, mining, foundation work, and tunnel projects widely use it.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Key Parameters of Hydraulic Splitting Rod

| Model | YG-110 | |||

| Length | 900mm | |||

| Punch depth | >1000mm | |||

| Punch diameter | 100mm | |||

| Crack width | 10~20mm | |||

| Splitting time | 10~15s | |||

| Splitting force | s | |||

| Weight | 39Kg | |||

How A Hydraulic Piston Rock Splitter Works

The Hydraulic Splitting Rod uses high-pressure oil to push a piston inside the rod. This piston pushes two wedges outward. These wedges apply force on the rock wall and split it from the inside.

The working steps:

- Drill a hole in the rock using a rock drill.

- Insert the splitting rod into the hole.

- Start the hydraulic pump to provide pressure.

- Rock breaks silently in seconds.

The process is simple, fast, and much safer than explosives.

Features Of Piston Rock Splitter

The Rock Splitting Rod has many useful features:

- Quiet Operation: No blasting noise, no dust

- Safe to Use: No vibration or flying debris

- Powerful Force: Splitting force up to 1000 tons

- Cost-Efficient: Low operation cost

- Long Tool Life: Made from strong alloy steel

- Easy to Transport: Lightweight and simple setup

It is ideal for construction jobs with noise limits or in sensitive areas like cities and near buildings.

Difference Between Hydraulic Splitting Rod And Hydraulic Rock Splitter

Many people confuse the Hydraulic Splitting Rod with the Hydraulic Rock Splitter. Here are the main differences:

| Feature | Hydraulic Splitting Rod | Hydraulic Rock Splitter |

|---|---|---|

| Shape | Long and slim | Larger wedge and cylinder |

| Hole Diameter | 42–50 mm | 90–110 mm |

| Working Depth | Up to 2 meters | Shorter depth |

| Best Use | Narrow/deep holes | Large surface rocks |

| Power Requirement | Lower | Higher hydraulic flow |

If your job requires deep drilling or work in tight spaces, the Hydraulic Splitting Rod is a better option.

Application Of Piston Rock Splitter

The Hydraulic Splitting Rod for Quarrying is widely used in:

- Stone Quarries: Breaking big blocks for cutting

- Mining Projects: Removing hard rocks underground

- Urban Construction: Breaking foundation rocks near buildings

- Bridge Demolition: Quiet splitting of strong supports

- Mountain Roads: Clearing boulders for road building

It works well in both granite and limestone and is good for both indoor and outdoor projects.

Common Questions About Hydraulic Splitting Rod

- What hole size is needed?

Operators typically drill 42-50 mm holes using a DTH or hand-held rock drill. - How long does it take to split one rock?

30 seconds to 2 minutes, depending on size and type. - Can it be reused?

Yes. The rod can be used over 1000 times with proper care. - Is it safe for use near buildings?

Yes. It creates no vibration, noise, or dust. - What equipment is needed?

You need a hydraulic station and a drill for the hole. - Can it work in cold areas?

Yes. It operates from -20°C, ideal for mountain or winter use.

WhatsApp/WeChat/Phone: 86 138 3715 9132