The Electric Wire Saw (an Electric Wire Saw Machine) is a cutting-edge tool designed for precise and efficient material processing. It uses a diamond-embedded wire driven by an electric motor to slice through tough materials like concrete, stone, metal, and composites. YG’s Electric Wire Saw combines portability and power, making it ideal for construction, mining, and manufacturing professionals. WhatsApp/WeChat/Phone +86 138 3715 9132

| Electric Wire Saw Machine Parameters | ||

| Model | YG-22 | |

| Main power | 22kw | |

| Voltage | 380v,50hz,single pahse | |

| Rated speed | 975r/min | |

| Main flywheel diameter | 500mm | |

| Max wire storage | 20-120m | |

| Walking motor power | 200W | |

| Maximum traverse distance | 2000mm | |

| Weight | 360kg | |

| Dimension | 800*800*2100mm | |

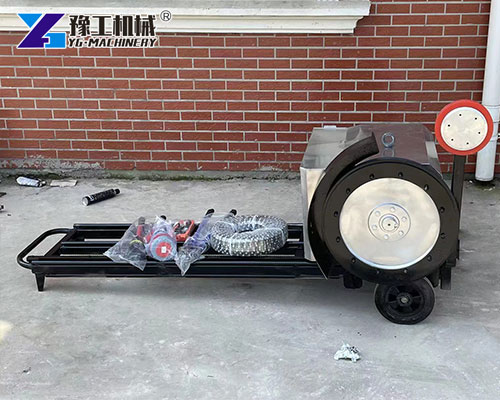

Accessories for Electric Wire Saw Machines

To maximize performance, YG offers a range of accessories for its Electric Wire Saw Machines:

Diamond Cutting Wires: Available in various lengths and bead configurations for different materials.

Cooling Systems: Water-based systems reduce heat and dust, prolonging tool life.

Guide Wheels: Ensure straight cuts and prevent wire deviation.

Spare Parts Kits: Include replacement bearings, brushes, and connectors for quick repairs.

Carrying Cases: Protect equipment during transit.

Electric Wire Saw Features

YG’s Electric Wire Saw stands out due to its innovative design and user-focused features:

Variable Speed Control: Adjust cutting speed according to material type for precision.

Low Vibration Technology: Reduces operator fatigue and ensures smooth, clean cuts.

Tool-Free Installation: Quick setup of wires and accessories without additional tools.

Energy Efficiency: High-power output with minimal energy consumption.

Durable Construction: Built with corrosion-resistant materials for long-term reliability.

Applications of Diamond Wire Cutting Machines

In construction, they break down concrete walls, slice through steel bars, and create neat openings in buildings.

For stoneworkers, these tools shape marble and granite blocks into slabs or sculptures with smooth edges.

Metal fabricators use them to cut aluminum, steel, or alloy sheets precisely, reducing waste.

Aerospace teams rely on diamond wire cutting to shape lightweight composites for airplane parts.

Even archaeologists use YG’s machines to safely free ancient artifacts trapped in rock or concrete without damage.

The machines adapt to tight spaces, tough materials, and messy environments, making them a go-to choice for professionals who need fast, clean results.

Safety Guidelines for Electric Wire Saw Operation

Stay safe while operating an Electric Wire Saw with these simple steps:

Wear protective gear like gloves, goggles, earplugs, and dust masks to shield yourself from debris and noise.

Hold materials steady using clamps or stands to prevent sliding during cuts.

Check the machine before use: inspect the cutting wire for damage, ensure proper oil levels, and verify electrical plugs are secure.

Work in a well-ventilated space and use water sprays to reduce dust and heat buildup.

Get trained on the machine’s controls and safety rules to avoid mistakes.

Following these guidelines helps prevent accidents and keeps your work efficient. YG’s machines include clear safety manuals to support safe operation.

Hydraulic vs. Electric Wire Saw

Hydraulic and electric wire saws are both used for precision cutting, but they differ significantly in operation and applications. A Hydraulic Wire Saw relies on hydraulic power, offering high torque for heavy-duty tasks like cutting thick concrete or reinforced steel. However, it requires a hydraulic pump, making it bulkier and less portable. Maintenance costs can also be higher due to hydraulic system complexity.

In contrast, an Electric Wire Saw (or Electric Wire Saw Machine) uses an electric motor, providing lightweight portability and ease of use for on-site projects. It’s ideal for smaller-scale jobs, such as stone cutting or metal fabrication, and eliminates the need for additional equipment like pumps. While electric models may lack the raw power of hydraulic systems, they offer quieter operation, lower maintenance, and cost-effective performance for most general applications.

Choose a hydraulic saw for extreme power and durability in industrial settings, or an electric model for versatility and convenience in lighter, more accessible tasks.

Why Choose YG’s Electric Wire Saw Machines?

YG’s Electric Wire Saw Machines deliver affordable, reliable performance for professionals. Budget-friendly pricing with low maintenance costs ensures long-term savings. Their custom solutions include tailored models for construction, mining, and other industries, adapting to tight spaces or heavy-duty tasks. Built with durable materials and user-friendly features like variable speed control, these machines cut concrete, stone, or metal efficiently and safely. Trusted by contractors worldwide, YG’s tools offer consistent results and adaptability, making them ideal for projects big or small. WhatsApp/WeChat/Phone +86 138 3715 9132