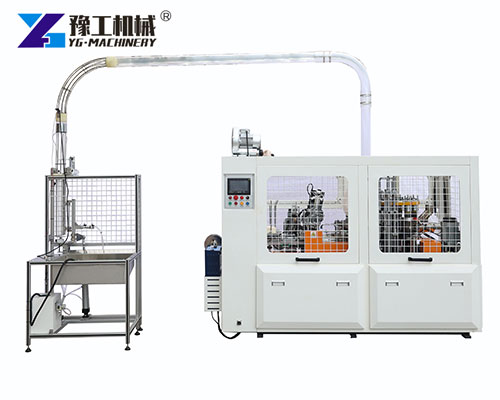

A paper cup forming machine is specialized equipment used to produce disposable paper cups for hot and cold beverages. It automatically completes the processes of feeding paper, sealing, bottom punching, heating, curling, and cup stacking. These machines are widely used in the food packaging industry, coffee shops, and takeaway businesses.

By using a paper cup forming machine, manufacturers can ensure high productivity and uniform quality while reducing labor costs. It is a crucial piece of equipment for any business looking to mass-produce eco-friendly disposable cups.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Paper Cup Forming Machine Parameters

| Mould Driving Method | Cam |

| Approximate Max. Forming Area | 660 x 300 mm |

| Approx. Running Speed | 15-30 strokes/min approx. during production |

| Approx. Sheet width required for feeding | 500 – 660 mm in rolls. |

| Mode of the cutting arrangement | In mold automatic |

| Sheet thickness Range | 0.20 – 2.0 mm |

| Material | PP, PS, PET, PVC, PLA |

| Max. Draw depth, i.e., cup length | 140 mm (Could be a special design) |

| Oil Pump Motor Power | 11KW, 6P |

| Sheet Feeding Motor | 2.2KW |

| Max. Sheet roll diameter | 800 mm |

| Heating arrangement | Top + bottom heating with IR Ceramic Heater(120pieces, 650W) |

| Temperature Controller & Thermocouple | PID K-Type |

| Type of Mould | Multi cavity 1 – 3 rows. |

| Approx. Electrical Consumption | 45KW/hr |

| Approximate Dimension | L3100×W1500×H2500 (mm) |

| Approximate Weight | 4000Kg |

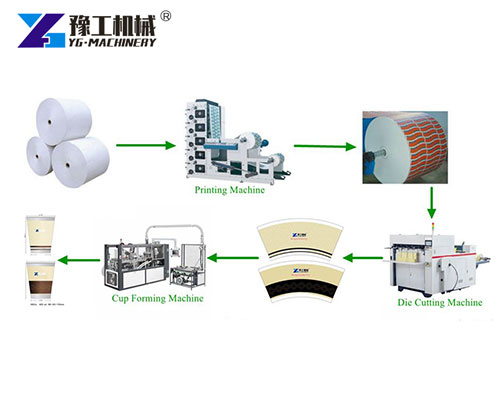

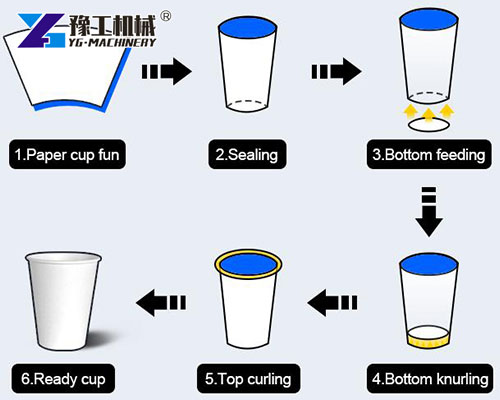

Working Process Of The Automatic Paper Cup Machine

The automatic paper cup machine streamlines production through the following steps:

- Paper Feeding: Printed or blank paper rolls are automatically fed into the machine.

- Side Sealing: The paper is curled into a cylindrical shape and sealed with heat.

- Bottom Cutting and Sealing: A separate paper roll is punched to form the bottom, then sealed to the cup body.

- Heating and Knurling: The cup bottom is heated to strengthen the seal.

- Rim Curling: The cup rim is curled to create a smooth edge for drinking.

- Automatic Ejection: Finished cups are ejected and stacked neatly.

This process ensures fast, hygienic, and consistent production, which is essential for large-volume manufacturers.

Features Of The Paper Cup Forming Machine

Our paper cup forming machines are built with advanced technology and a user-friendly design. Key features include:

- High-Speed Production: Up to 120 cups per minute, depending on the model.

- Stable Operation: Precision mechanical parts reduce breakdowns.

- Smart Control System: PLC control with touch screen interface.

- Energy Efficient: Low power consumption design.

- Flexible Cup Sizes: Compatible with 2oz to 22oz cup formats.

These features ensure smooth and continuous operation, even during long production hours.

Applications Of Paper Cup Making Equipment

The paper cup-making equipment is used in a wide range of industries:

- Food and Beverage Chains: For coffee, tea, soft drinks, and soup containers.

- Catering and Takeaway Services: Ideal for fast food and mobile food businesses.

- Event Organizers: Disposable solutions for concerts, fairs, and sports venues.

Its versatility makes it a practical investment for small businesses and large manufacturers alike.

Why Choose Our Paper Cup Machines?

Our machines are designed for international buyers who need reliable performance, high speed, and great value.

- China-Made, Global Quality: Our machines are made in China, offering a better price-to-performance ratio than Western brands.

- Factory Direct Price: We provide factory-direct sales, reducing unnecessary costs.

- OEM/ODM Support: Custom logo, color, and function options are available.

- Full Production Line Available: We offer printing machines, paper slitting machines, and cup collection devices.

- Global Success Cases: Shipped to USA, Germany, Spain, Australia, UAE, and more.

These advantages help our clients succeed in the competitive disposable packaging market.

How To Choose The Right Model?

To select the most suitable paper cup forming machine, consider:

- Paper Type: PE-coated, PLA-coated, or double-layer paper

- Cup Size Range: Check the minimum and maximum sizes you need

- Daily Output: Estimate your target production volume

- Local Power Supply: Match voltage and frequency

- Budget: Set a budget for the machine, tools, and spare parts

We offer expert consultation to help you match the machine with your specific needs.

Factors That Affect Disposable Cup Machine Price

Understanding the disposable cup machine helps you make a wise investment. The price can vary based on:

- Production Capacity: Machines with higher output cost more.

- Cup Size Range: Multi-size compatible machines are more complex.

- Automation Level: Fully automatic machines are more expensive than semi-automatic ones.

- Add-On Functions: Features like cup counting, stacking, and remote monitoring increase the price.

- Material Compatibility: Machines that support both single and double-PE-coated paper have a higher cost.

We help you choose the right model based on your budget and production needs.

Packaging & Shipping Of Disposable Cup Production Machine

Each disposable cup production machine is packed carefully to ensure safe delivery:

- Strong Wooden Case: Export-grade, fumigated wooden packaging.

- CE Certification: Fully compliant with European safety standards.

- Clear Instructions: Includes operation manual and training videos.

- Voltage Options: Compatible with 220V / 380V (50Hz / 60Hz), adaptable for EU and US power grids.

Our experience with international shipping ensures your machine arrives safely and ready for use.

YG Machinery After-Sales Support

We provide professional after-sales service for every paper cup forming machine sold:

- Online Technical Support: Available 24/7

- Video Training: For machine installation and maintenance

- One-Year Warranty: Covers mechanical and electrical parts

- Spare Parts Available: Quick replacement parts shipping worldwide

Our support ensures you can keep your production running smoothly.

WhatsApp/WeChat/Phone: 86 138 3715 9132