What Is a Rebar Rib Peeling and Threading Machine?

A Rebar Rib Peeling and Threading Machine is used to strip the ribs off steel bars and create threads at the ends. These threads help connect rebars using mechanical couplers instead of welding. It ensures stronger, more stable joints in concrete structures.

This machine plays a key role in rebar connection during construction. It streamlines the joint process, making it faster, more reliable, and consistent across projects.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Why Use a Rebar Threading Machine for Rib Peeling?

Compared to traditional welding or manual threading, a Rebar Thread Rolling Equipment offers major benefits:

- Faster and more consistent threading speed

- Stronger and safer rebar joints with no welding cracks

- Standardized construction process that reduces error

- Easy to use with straight-thread couplers

This machine boosts efficiency and lowers labor costs while meeting modern construction standards.

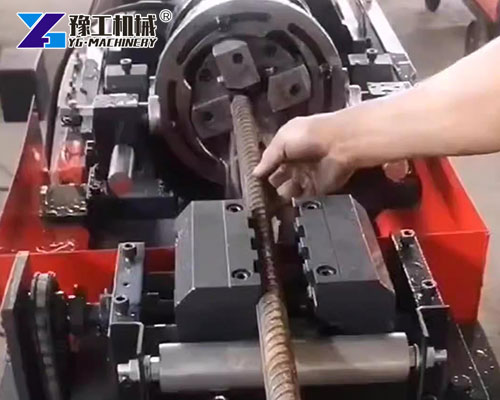

Working Principle of Rebar Rib Peeling and Threading Machine

The rebar processing goes through four main steps:

- Rib Peeling

- Thread Rolling

- Thread Forming

- Quality Inspection

Each stage is essential to ensure that the final threaded rebar meets the strength and accuracy required for safe construction applications.

Main Structure of the Steel Bar Threading Machine for Sale

Key components of the machine include:

- Clamping Device: Holds the rebar firmly

- Guiding System: Keeps alignment during cutting

- Main Spindle: Drives the peeling and threading tools

- Motor and Gearbox: Powers the machine with steady torque

- CNC Control System: Manages the process with precision

This clear design ensures accurate and efficient rebar threading every time.

Key Features of Our Rib Peeling and Threading Machine

Our Automatic Rebar Rib Peeling & Threading Machine includes several advanced features:

- Integrated peeling and threading in one unit

- CNC system for automatic feeding and thread control

- Adjustable thread length and diameter

- Error detection and safety stop system

It’s compact, user-friendly, and ideal for factory or site use.

Application Scenarios of Steel Bar Threading Machine

The Steel Bar Threading Machine for Sale is suitable for:

- Bridge construction

- High-rise buildings

- Tunnel and subway projects

- Prefab component factories

- Rebar processing centers

Its versatility makes it a great choice for both small and large-scale projects.

How to Operate the Machine Safely

To ensure safe and smooth operation:

- Clap the rebar tightly into position

- Start rib peeling with the control panel

- Proceed to thread rolling once peeling is complete

- Remove the finished rebar

Safety Tips:

- Always wear gloves and goggles

- Keep the machine clean and free of debris

- Check tool alignment before each use

- Perform daily maintenance checks

Following these steps ensures worker safety and machine longevity.

Customer Case

Case 1: Middle East Bridge Project

A construction firm in the Middle East replaced traditional welding with our machine. They improved connection strength and reduced on-site labor, saving 30% on total time.

Case 2: Southeast Asia Precast Factory

A client in Southeast Asia adopted our machine for factory rebar processing. It helped boost production speed by 40% and reduced manual errors significantly.

Why Choose Our Rebar Rib Peeling and Threading Machine?

- High-quality build with CE and ISO certification

- Professional after-sales support and training

- Remote technical assistance

- Full supply of spare parts

- Video guides for fast learning

We help customers set up, run, and maintain their machines easily.

Our rebar threading machines offer strong performance, safe design, and easy operation. Contact us now to get a quote, schedule a trial, or buy a Rebar Rib Peeling and Threading Machine directly for your site.

WhatsApp/WeChat/Phone: 86 138 3715 9132