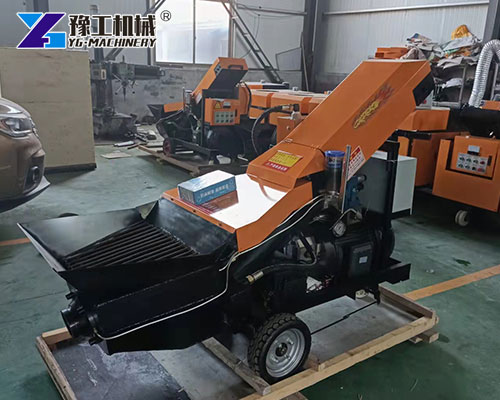

Many sites cannot use large pumps. Big pumps cost a lot and take up space. A mini concrete pump machine solves this. It is small, easy to move, and fits tight spots. It lets teams work faster and with fewer people. This machine is the right tool when large pumps are too big or too costly.

What Is A Mini Concrete Pump Machine?

A Mini Concrete Pump Machine is a small machine that moves concrete from the mixer to the place you need. It pushes concrete through pipes. Workers do not need to carry concrete by hand. The machine is made for small and mid-size jobs.

Key parts and design:

- Simple hopper to take concrete.

- A hydraulic system to push material.

- Pipes and connectors for pumping.

- An engine or motor that runs the pump.

This machine is easy to clean. It has fewer parts than big pumps. It is made to be strong and simple.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Horizontal Concrete Pump: Flat Site Option

A Horizontal Concrete Pump is a model that works best on flat land. It pumps concrete in a nearly straight line. This type is good for low-rise houses and road work.

Advantages for flat sites:

- Easier setup on level ground.

- Stable pumping with low lift.

- Simple pipe layout and quick start.

Use a horizontal concrete pump when you need a steady flow and a low height. It saves time on flat jobs.

Parameter

Model: 10 type fine stone secondary pouring pump

Motor power: 15kw

Work efficiency: 6m³/h

Maximum pressure: 15MPa

Working pressure: 10MPa

Aggregate size: 0.5-1.5cm

Vertical conveying distance: 20m

Horizontal conveying distance: 50 meters

Diameter of conveying pipe: 80mm

Whole machine weight: 600kg

Dimensions: 1800x700x1100mm

Inclined Concrete Pump: Slope And High Lift Use

The Inclined Concrete Pump is for jobs with height or slope. It can push concrete up a hill or to higher floors. This model is made with stronger pressure and is fit for sloped sites.

When to choose an inclined pump:

- Building on hills or sloped land.

- Pumping to higher floors of a house.

- Sites where pipes must go up steps or ramps.

The inclined pump gives more lift. It keeps a stable flow even when the line goes up.

Parameter

Model: Miniature fine stone secondary pouring pump (inclined type)

Motor power: 15KW

Work efficiency: 6m³/h

Through particles: ≤3cm

Conveying distance: (aggregate 1-3cm, head 10m, horizontal 20m)

(Aggregate 1-2cm, head 15m, level 40m)

Whole machine weight: 360kg

Dimensions: 1800x750x1200mm

How The Mini Concrete Pump Machine Works

The flow is easy to follow. It has clear steps. Workers see the whole process at once.

Working steps:

- Concrete enters the hopper from the mixer.

- The hydraulic system pushes material into the pumping cylinder.

- The pump sends concrete into the pipe.

- Workers guide the pipe and place concrete at the point needed.

Key technologies that help:

- Hydraulic drive for steady force.

- Wear-resistant pipes to last longer.

- Efficient motors to save energy.

This simple flow makes the mini pump both fast and reliable. It helps teams pour without heavy lifting.

Portable Concrete Pump Machine: Mobility

A portable concrete pump machine is made for moving between sites. It is light and easy to tow or carry. Teams can place it close to work and save time.

Portable pump features:

- Wheels or a small trailer mount.

- Fast setup and teardown.

- Low fuel or electric power options.

This pump cuts the need for many workers. It also lowers transport time and cost. For small contractors, portability makes the job easier.

Benefits Of Using A Mini Concrete Pump Machine

Using a mini pump gives clear gains. It helps projects finish faster and with less cost.

Main benefits:

- Save Labor: Fewer workers are needed to move concrete.

- Speed Up Work: Pumping is faster than wheelbarrows or buckets.

- Better Quality: Cement placement is smoother and more even.

- Lower Cost: Less labor and time mean lower total cost.

- Use In Tight Spaces: Works where large pumps cannot enter.

These points make the mini pump the smart choice for many builds.

Applications Of Mini Concrete Pump Machine

The mini pump fits many job types. It is flexible for both urban and rural work.

Best application areas:

- Home building and repairs.

- Small commercial projects.

- Road repair and small bridge sites.

- Sites with narrow access or complex layout.

This small concrete pump for construction is widely used in home building, road works, and repair projects where big pumps are not suitable.

How To Choose The Right Mini Concrete Pump Machine

Pick a pump that matches your job. Think about these factors before you buy.

Key selection points:

- Project Size: Match pump output to daily concrete needs.

- Power Type: Choose diesel or electric by the site’s power supply.

- Pipe Layout: Check if you need horizontal or inclined pumping.

- Capacity: Look at the hopper and flow rate numbers.

- Service: Choose a brand with parts and support.

Compare models side by side. Ask about warranty and spare parts. A small check now saves time later.

Simple Maintenance Tips

Small care keeps the pump working long and well.

Daily care:

- Clean the hopper and pipes after use.

- Check oil and hydraulic fluid levels.

- Inspect pipes for wear and replace them early.

Good maintenance lowers daily cost and keeps the pump ready for work.

Contact Us For Mini Concrete Pump Machine

If you need help, contact our sales team. Tell us your project size and site layout. We can recommend the best mini pump model, such as a horizontal concrete pump or an inclined concrete pump. We also offer diesel concrete mixers, small concrete mixer pumps, crawler-type mixing pumps, and mobile concrete mixer pumps.

A mini concrete pump machine can change how you work. Ask us for a quote today and see how it fits your next project.

WhatsApp/WeChat/Phone: 86 138 3715 9132