The market for eco packaging is growing fast. Consumers want greener choices. A Paper Bowl Machine lets you join this trend. It makes disposable paper bowls that meet food safety rules. Many small and large food firms now use a Disposable Paper Bowl Machine to save costs and win customers.

What Is A Paper Bowl Machine?

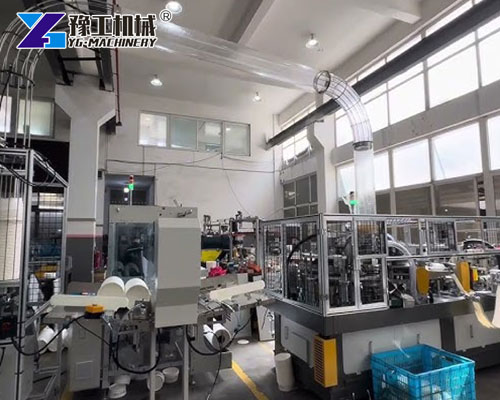

A Paper Bowl Making Machine is a specialized industrial device designed to efficiently produce single-use paper bowls for food packaging. It is the heart of any modern disposable packaging facility.

This complex equipment takes pre-cut or rolled paper stock and automatically transforms it into finished bowls. The core function of the machine is to manage all stages of the manufacturing process without human intervention. This automated capability is why it is widely used across:

The general food industry (packaging instant noodles, soup, or ice cream).

The large-scale catering sector and fast-food chains.

Beverage packaging companies require specialty containers.

The process involves precision steps, including paper feeding, heating, ultrasonic sealing, molding, curling the rim, and final output.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Paper Bowl Machine Features

YG builds robust machines with long life and low service needs.

Key points:

- Full automation from feed to output.

- PLC control for stable operation.

- Made of stainless steel for food safety.

- Spare parts are ready for global shipping.

High Speed Paper Bowl Machine Parameters

YG offers several models. Below are typical specs and a reference to High Speed Paper Bowl Machine Price factors

| Model | YG-35S |

| Cup size | 6-44oz |

| Raw material | 160- 280g/㎡Single and double PE-coated paper |

| Top diameter | Φ90-Φ140mm |

| Bottom diameter | Φ75-Φ115mm |

| Height | 40-110mm |

| Bottom depth | 5-12mm |

| Capacity | 70-90pcs/min |

| Main motor power | 2.2kw |

| Energy consumption | 9.5kw |

| Total power | 17.5kw |

| Air source | 0.4m/min,0.5-0.8Mpa |

| Weight | 3.5t |

| Dimension (LxWxH) | 2910x1400x1800 mm |

Price factors (affect High Speed Paper Bowl Machine Price):

- Machine model and speed

- Optional molds and logo stamp

- Voltage and export package

- After-sales package and training

Main Advantages Of Using A Paper Bowl Machine

YG machines give clear benefits for producers.

- Hygienic And Eco

- Use food-grade paper and bio-coatings.

- No plastic in many options.

- High Productivity

- Continuous work, a few stops.

- Reduce labor cost.

- Stable Quality

- Each bowl has a neat edge and shape.

- Easy Maintenance

- Modular parts, fast to clean.

- Low Waste

- Precise feed reduces paper loss.

How the Paper Bowl Making Machine Works

- Paper roll loading

- Pre-heating of paper

- Forming and molding

- Edge sealing by heat or glue

- Trimming and punching

- Bowl discharge and stacking

Each unit can be set to different bowl sizes by changing molds. The change is fast. This suits multi-product lines.

Disposable Paper Bowl Machine Applications

Where you can use the Disposable Paper Bowl Machine:

- Food factories making ready meals

- Catering companies for events

- Restaurants and cloud kitchens making to-go bowls

- Packaging suppliers selling eco bowls to retail

Customer Case Study

A UAE packer bought a YG-B600 machine. Results in one month:

- Output rose 40%

- Labor needs dropped by 30%

- Product passed food export tests

Customer comment: “The YG Paper Bowl Machine runs steadily. We now offer eco bowls to big hotels.”

How To Choose The Right Paper Bowl Machine

Follow simple steps:

- Decide bowl sizes and daily output.

- Pick speed (70–90 pcs/min).

- Choose a power supply and voltage.

- Ask about spare parts and warranty.

- Get a demo video or sample bowls.

After-Sales And Service From YG

YG provides full support:

- Installation guidance and remote training.

- Spare parts delivery and fast response.

- CE / ISO quality certificates.

- Optional on-site startup service if needed.

Why Choose YG as Your Paper Bowl Machine Manufacturer?

We offer more than just machinery; we offer a partnership built on trust, quality, and support. As an experienced Paper Bowl Machine Manufacturer, our commitment extends long after the sale.

Complete Product Range: We offer a full line of related equipment, including Paper Cup Forming Machines, Paper Cup Lid Making Machines, and other disposable paper product lines, allowing you to scale your business seamlessly.

Decades of Industry Experience: A strong manufacturing history backed by numerous global client case studies.

Comprehensive After-Sales Support: This includes professional installation and training, rapid remote diagnosis, and reliable spare parts supply.

International Quality Certification: All equipment is certified to international standards, including CE and ISO.

WhatsApp/WeChat/Phone: 86 138 3715 9132