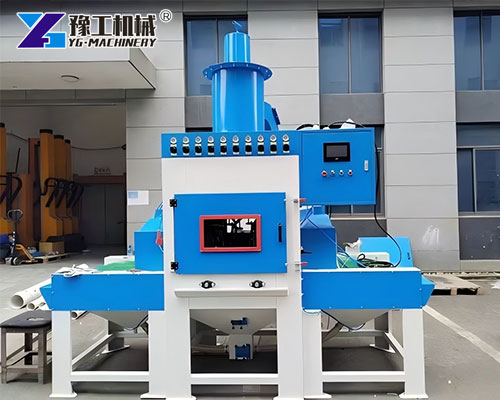

The automatic sand blasting machine is a machine that uses high-pressure air or mechanical power to shoot small particles (like steel sand, glass beads, or ceramic sand) at high speed onto a workpiece’s surface. By hitting and rubbing against the surface, it cleans the workpiece, makes it stronger, removes rough edges, or creates a rough texture. Contact us via WhatsApp/WeChat at +86 138 3715 9132

Parameters of the Automatic Sand Blasting Machine

| Model | YG-600 | YG-700 | YG-800 | YG-1000 |

| Volume(m3) | 0.26 | 0.3 | 0.6 | 1 |

| Height | 1150 | 1250 | 1700 | 2000 |

| Sand peening capacity | 5-10(m3/h) | 6-11(m3/h) | 10-12(m3/h) | 10-30(m3/h) |

| Air source configuration | 3(m2/h) | 3(m2/h) | 3.5(m2/h) | 4(m2/h) |

| Control System | Air control | Air control | Air control | Air control |

| Diameter | 600mm | 700mm | 800mm | 1000mm |

6 Key Features of Automatic Sand Blasting Machines

- Programmable Automation: Pre-set blasting patterns for uniform results across batches.

- Multi-Axis Nozzle Movement: 360° coverage for complex geometries.

- Energy Efficiency: Low air consumption designs (e.g., 10–15 CFM) reduce operational costs.

- Modular Design: Easily adjustable chambers for varying workpiece sizes.

- Safety Interlocks: Emergency stop systems and hermetic seals to prevent abrasive leaks.

- Real-Time Monitoring: Sensors track pressure, media levels, and performance metrics.

Basic Components of an Automatic Sand Blasting System

- Blasting Chamber: Enclosed space where the surface treatment occurs, often with conveyor belts for continuous material flow.

- Abrasive Media Hopper: Stores the abrasive material (e.g., sand, steel shot) and feeds it into the blasting mechanism.

- High-Pressure Nozzle System: Delivers abrasives at controlled speeds (up to 150 mph) for precise surface impact.

- Dust Collection Unit: Filters and recycles spent abrasives while minimizing airborne particles for safety.

- Control Panel: Automates parameters like pressure, nozzle movement, and conveyor speed for consistent results.

How Automatic Sand Blasting Machines Work

- Material Loading: Workpieces are placed on a conveyor belt or turntable and fed into the blasting chamber.

- Abrasive Propulsion: A high-pressure air or centrifugal wheel system accelerates abrasives through nozzles onto the surface, removing contaminants or creating texture.

- Waste Management: Used abrasives and debris fall into a recovery system, where clean media is separated and recycled, while dust is filtered.

- Finishing: The treated workpiece exits the chamber, ready for painting, coating, or further processing.

Types of Abrasive Materials Used

- Sand/Garnet: Coarse abrasives for heavy-duty rust removal or surface etching.

- Glass Beads: Gentle option for delicate surfaces (e.g., aluminum, plastics) to achieve a smooth, matte finish.

- Steel Shot/Grit: High-impact media for deburring metal parts or enhancing adhesion for powder coating.

- Walnut Shells: An eco-friendly, non-destructive choice for cleaning organic materials or fragile components.

Benefits of Using a Sand Blasting Machine

Enhanced Productivity

Processes large volumes up to 5x faster than manual methods, ideal for 24/7 manufacturing lines.

Uniform Finishing

Consistent pressure and nozzle control eliminate human error, ensuring identical results across all parts.

Cost Savings

Reduces labor costs by 70 %+ and minimizes material waste through abrasive recycling.

Safety Improvements

Fully enclosed systems protect operators from dust, noise, and abrasive exposure.

Low Maintenance

Durable steel construction and self-cleaning filters reduce downtime for repairs.

Applications of Automatic Sand Blasting Machines

- Automotive Industry: Removing old paint from car bodies; preparing surfaces for primer.

- Aerospace: Cleaning aircraft components and removing thermal coatings from turbine blades.

- Manufacturing: Deburring castings, descaling steel beams, or texturing gear surfaces for grip.

- Art & Restoration: Delicate cleaning of sculptures or historic metalwork without damage.

- Marine: Removing barnacles and rust from ship hulls before anti-corrosive coating.

Choosing the Right Sandblasting Machine

Key Factors

- Surface Area: Small chambers (e.g., 2m³) for individual parts; industrial-sized units (10m³+) for large machinery.

- Material Hardness: Use steel grit for heavy metals; opt for glass beads on soft alloys.

- Throughput Needs: Conveyor-based systems for high-volume production; batch-style machines for small runs.

Abrasive Selection Guide

| Application | Recommended Media | Finish Type |

| Rust Removal | Steel Shot/Garnet | Rough, etched |

| Paint Stripping | Aluminum Oxide | Smooth, clean |

| Delicate Cleaning | Walnut Shells | Non-destructive |

Automatic Sand Blasting Machine Manufacturer – YG Machinery

Automatic sand blasting machines have a wide range of applications and are not very expensive. Many customers will choose to use YG sandblasting machines. Because we not only have advanced technology, but also have equipment that is more in line with customer experience, as well as professional sales staff and after-sales teams. Therefore, when purchasing YG equipment, you don’t need to worry too much, because it will bring you a perfect experience.

Contact us via WhatsApp/WeChat at +86 138 3715 9132