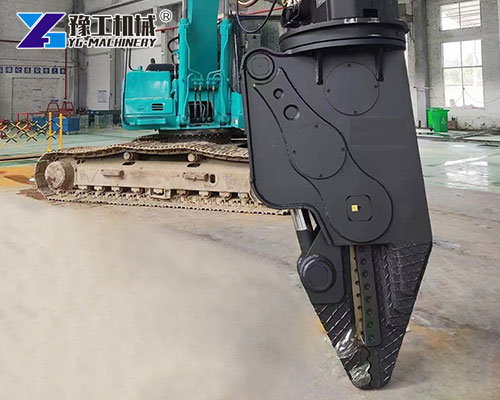

Car demolition shears (sometimes called auto‑recycling shears or scrap shears) are heavy‑duty hydraulic cutting attachments used to dismantle end‑of‑life vehicles quickly and safely. Mounted on excavators, material‑handlers, or dedicated demolition rigs, they slice through car bodies, chassis rails, engines, and drive‑trains so the separated metals can be fed efficiently into shredders or balers.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of Car Demolition Shears for Excavator

| Model | Unit | YG-08A |

| Suitable Excavator | T | 18-24 |

| Carrier Weight | KG | 1600 |

| Opening | MM | 850 |

| Blade Length | MM | 2-2*230 |

| Height | MM | 2530 |

| Width | MM | 1430 |

| Driving Pressure | KGF/CM2 | 320 |

| Driving Flow | LPM | 200-250 |

| Maximum Cutting Force | TON | 50 |

| Open Cycle Time | SEC | 2.3 |

| Close Cycle Time | SEC | 2.9 |

Advantages of Car Demolition Shears

Stronger, Faster, Safer—Key Benefits

- Extreme Cutting Force

Dual hydraulic cylinders deliver up to 800-ton jaw force, severing frames and axles in one pass. - 360° Continuous Rotation

Operators position the shear without repositioning the excavator, boosting hourly throughput. - Replaceable AR500 Blades

Wear‑resistant knives last longer and swap out in minutes, minimizing downtime. - Integrated Auto‑Lube

Central greasing keeps pivot pins protected, extending service life. - Low Noise & Zero Sparks

Cold cutting reduces fire risk compared with oxy‑fuel methods, essential for yard safety and compliance.

By adopting car demolition shears, yards typically see a 40 % productivity gain and a 25 % drop in operating costs within the first year.

How Excavator Scrap Shears Work

Hydraulic cylinders deliver several hundred tonnes of closing force.

A fixed jaw and a movable jaw—each with replaceable, wear‑resistant blades—act like a huge pair of scissors.

Integrated speed/pressure valves shift automatically: high flow for fast opening‑closing, high pressure for the cutting stroke.

Rotation motors (360 ° continuous or 180 ° swing) let the operator align the jaws precisely on complex vehicle structures.

Applications of Scrap Shear for Excavator

- Automotive Recycling Centers – Rapid car body downsizing for balers or shredders.

- Mixed Scrap Yards – Processing buses, light trucks, railway cars, and farm equipment.

- Industrial Demolition Sites: Remove steel beams, tanks, and heavy plates before the torch crews arrive.

- Port & Shipyard Operations – Downsizing containers and marine structures for export.

Wherever tough steel must be cut quickly, car demolition shears outperform torches or mechanical crushers.

Choosing the Right Excavator with Scrap Shear for Sale

Selecting the appropriate excavator with scrap shear for sale is a crucial decision that depends on your specific operational needs and the types of materials you handle. Consider the following factors when making your choice:

- Excavator Size and Capacity: Ensure the shear is compatible with the size and hydraulic capacity of your excavator. YG offers a range of shears designed for different excavator classes.

- Cutting Force Requirements: Evaluate the thickness and type of materials you will be processing to determine the necessary cutting force of the shear.

- Blade Design and Material: Different blade designs are optimized for specific materials. YG offers various blade options to suit your application. The quality of the blade steel is also critical for longevity and performance.

- Jaw Opening: The jaw opening of the shear dictates the size and shape of the materials it can process. Choose a size that accommodates your typical feedstock.

- Rotation Capabilities: Some shears offer 360-degree rotation, providing enhanced maneuverability and positioning for increased efficiency.

- Maintenance Requirements: Consider the ease of maintenance and the availability of spare parts. YG is committed to providing excellent after-sales support and readily available components.

Your Car Demolition Shear Manufacturer: YG Machinery

When you choose YG as your car demolition shear manufacturer, you are partnering with a company dedicated to quality, innovation, and customer satisfaction. Our strengths include:

- Experienced Engineering Team: Our shears are designed by a team of experienced engineers who utilize advanced technology and design principles to ensure optimal performance and durability.

- High-Quality Manufacturing: We employ stringent quality control measures throughout the manufacturing process, using premium materials and skilled craftsmanship to produce reliable and long-lasting equipment.

- Customization Options: YG understands that every operation is unique. We offer customization options to tailor our shears to your specific requirements.

- Comprehensive Support: We provide comprehensive after-sales support, including technical assistance, spare parts supply, and maintenance guidance, ensuring that you get the most out of your investment.

- Global Reputation: YG has built a strong global reputation for providing high-quality and reliable demolition and recycling equipment. Our commitment to excellence has made us a trusted partner for businesses worldwide.

WhatsApp/WeChat/Phone: 86 138 3715 9132