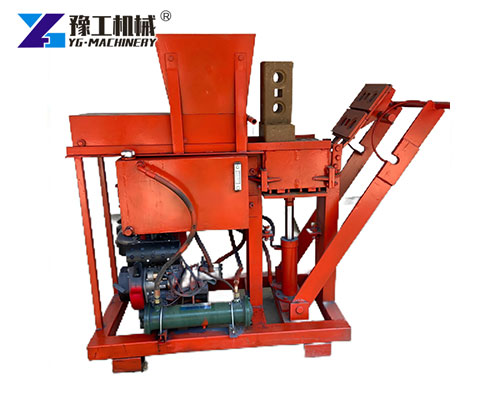

The Clay Brick Making Machine is a specialized piece of equipment used to produce clay bricks for construction and masonry purposes. These machines process raw clay into molded bricks that can be fired in kilns to harden and solidify them.

The core function of a clay brick-making machine is to automatically or semi-automatically mix, shape, and cut clay into uniform brick sizes. These machines come in various designs and scales, from manual machines suited for small-scale production to fully automated systems used in large industrial operations.

WhatsApp/WeChat/Phone +86 138 3715 9132

Parameters of Clay Brick Making Machine for Sale

| Model | YG-15 |

| Weight | 7800kg |

| Vibration intensity | 100KN |

| Machine power | 16kw |

| Period time | 15~20s |

| Control system | PLC system |

| Machine size | 3.15*1.8*2.4m |

| Molding method | Hydraulic molding |

How Does a Clay Brick Making Machine Work?

A typical clay brick-making machine works in a step-by-step process involving the following stages:

- Raw Material Preparation: The raw clay is first crushed and mixed with water to create a homogenous mixture. Some machines also include a mixing unit to ensure uniformity.

- Molding Process: The clay mixture is then shaped into bricks. The molding process can be either extrusion or compression. In extrusion machines, the clay is forced through a mold, while compression machines use hydraulic pressure to form the brick shape.

- Cutting: After molding, the clay brick is cut into the desired length and width using a wire cutter or an automatic cutting system.

- Drying: The freshly molded bricks are then left to dry in a controlled environment. Drying chambers or open-air drying areas may be used depending on the scale of production.

- Firing: Once the bricks are dry, they are fired in a kiln at high temperatures (around 1000°C to 1200°C) to harden and strengthen them.

Types of Clay Brick Machines

Automatic Clay Brick Machine

An Automatic Clay Brick Machine offers unparalleled efficiency and precision. These machines are equipped with advanced control systems that automate the entire brick-making process, from clay feeding to brick ejection. They can continuously produce a large number of bricks with consistent quality.

For example, YG’s Automatic Clay Brick Machine can adjust the molding pressure and shape according to different production requirements. With features like automatic material dosing and real-time quality monitoring, it reduces labor costs and human error, making it ideal for large-scale brick production plants.

Semi-Automatic Clay Brick Machine

Semi-automatic Clay Brick Machine models strike a balance between automation and manual operation. They require some human intervention, such as manually feeding the clay into the machine or adjusting certain parameters. However, they still offer significant advantages over completely manual methods.

Semi-automatic machines are more affordable than their fully automatic counterparts, making them a popular choice for small to medium-sized brick manufacturers. They are also more flexible in terms of production volume and can be easily adapted to different types of clay and brick designs.

Features of Clay Brick Making Machines

- High Productivity: Both automatic and semi-automatic Clay Brick Making Machine models from YG can produce a large number of bricks per hour. The Automatic Clay Brick Machine can churn out hundreds of bricks, while the semi-automatic models can still meet the demands of smaller-scale production efficiently.

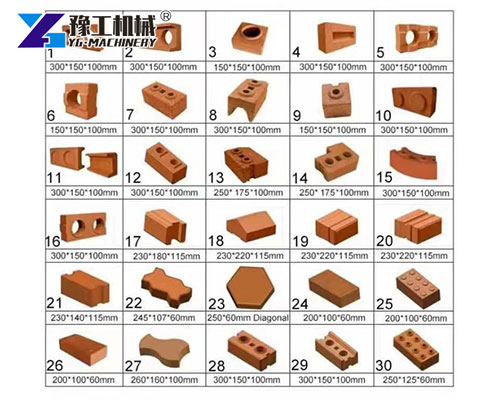

- Versatility: These machines can produce various types of clay bricks, including solid bricks, hollow bricks, and interlocking bricks. The Clay Brick Molding Machine components can be easily changed to create different brick shapes and sizes, catering to diverse construction needs.

- Energy Efficiency: YG’s clay brick-making machines, especially the Hydraulic Brick Press models, are designed to consume less energy during operation. The optimized hydraulic systems and mechanical designs reduce power consumption without sacrificing production quality.

- Durability: Built with high-quality materials and robust construction, the Clay Brick Making Machine can withstand the rigors of continuous use in harsh production environments. The key components are made from wear-resistant materials, ensuring a long service life and reducing maintenance costs.

Advantages of Clay Bricks

- Durability: Clay bricks produced by a reliable Clay Brick Making Machine are extremely durable. They can resist weathering, fire, and pests, making them a long-lasting building material. Their strength allows them to support heavy loads, contributing to the stability of structures.

- Aesthetic Appeal: Clay bricks offer a natural and classic look. They come in a variety of colors and textures, which can enhance the visual appeal of any building. Whether it’s a rustic cottage or a modern office building, clay bricks can add a touch of elegance.

- Sustainability: Clay is a natural and abundant resource. Using a clay brick-making machine to produce bricks is a relatively sustainable process. Additionally, clay bricks can be recycled at the end of a building’s life, reducing waste and environmental impact.

- Thermal Insulation: Clay bricks have good thermal insulation properties. They can help maintain a comfortable indoor temperature by keeping buildings cool in summer and warm in winter, reducing the need for excessive heating and cooling.

How to Choose a Clay Brick Machine

- Production Volume: Consider your production requirements. If you need to produce a large number of bricks continuously, an Automatic Clay Brick Machine is the best choice. For smaller projects or lower production volumes, a semi-automatic clay Brick Machine may be more suitable.

- Type of Bricks: Determine the types of bricks you want to produce. Different machines may have limitations in terms of brick shapes and sizes. Make sure the Clay Brick Making Machine you choose can handle the specific brick designs you need.

- Energy Consumption: Look for machines with high energy efficiency; lower energy consumption will reduce your operational costs over time.

- After-sales Service: Choose a manufacturer like YG that offers excellent after-sales service. This includes technical support, spare parts availability, and training for your operators.

Applications of Clay Brick Molding Machine

- Residential Construction: Clay bricks are a popular choice for building homes. A Clay Brick Making Machine can produce bricks that are used for walls, foundations, and decorative elements in residential buildings.

- Commercial Construction: In commercial projects such as office buildings, shopping malls, and hotels, clay bricks are used for their durability and aesthetic appeal. The consistent quality of bricks produced by YG’s machines meets the high standards of commercial construction.

- Infrastructure Projects: Clay bricks are also used in infrastructure projects like bridges, tunnels, and retaining walls. Their strength and stability make them suitable for these demanding applications.

- Restoration and Renovation: For historical restoration and renovation projects, clay bricks can be used to match the original building materials, preserving the architectural integrity of the structures.

Why Choose YG Clay Brick Making Machine

We offer a wide range of models, including Automatic Clay Brick Machine, Semi-Automatic Clay Brick Machine, to meet the diverse needs of our customers.Our commitment to quality is evident in every aspect of our products, from the selection of materials to the final assembly. We also provide comprehensive after-sales service, including training, technical support, and a quick response to any issues. WhatsApp/WeChat/Phone +86 138 3715 9132