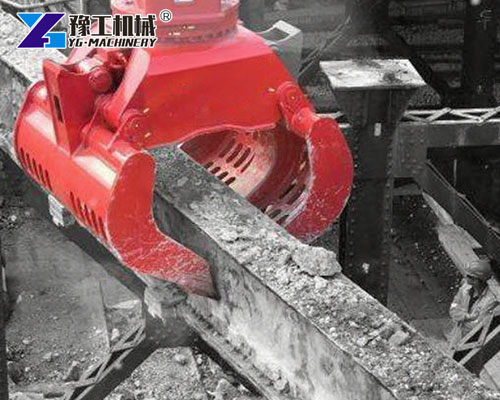

A Demolition Grapple for Excavator is a heavy-duty tool for tearing down structures, sorting debris, and loading materials. It mounts to your excavator and uses powerful jaws to grip concrete, rebar, timber, and mixed waste. YG designs models for 5–50-ton excavators, so small urban jobs and large industrial sites both have the right match. Key selling points include high-strength wear steel, optional 360° rotation for precise handling, and low maintenance needs to reduce downtime.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Hydraulic Demolition Grapple: Key Features And Options

A Hydraulic Demolition Grapple adds smooth, controlled movement and fast cycles. It is built for long service in tough environments.

- High-Strength Structure: Q355 main frames and NM400 wear plates resist impact and abrasion.

- 360° Hydraulic Rotation (Optional): Precise positioning without moving the machine; faster pick-and-place in tight spaces.

- Wider Jaw Opening: Grab more material per cycle; ideal for bulky concrete and tangled rebar.

- Twin Hydraulic Cylinders: Balanced, stable clamping force with less chance of slippage.

- Protective Hose Routing: Guards and internal passages reduce hose damage on rubble.

- Service-Friendly Pins And Bushes: Grease points are easy to reach for daily care.

- Custom Interfaces: Brackets and couplers to fit Cat, Komatsu, Hitachi, Doosan, Volvo, JCB, and more.

In daily use, a Hydraulic Demolition Grapple often cuts cycle time because operators can rotate, align, and grip in one motion.

Sorting Grapple Applications And Target Materials

A Sorting Grapple focuses on high-throughput handling after or during demolition. It must be agile, light enough for quick moves, yet strong at the edges and tips.

Common applications include:

- Building Demolition: Pull down masonry, pick concrete chunks, and separate rebar.

- Waste Sorting: Separate wood, metal, and concrete to reduce landfill costs.

- Recycling Yards: Load scrap into bins, feed crushers or shears, and prepare material streams.

- Forestry (Optional): Move logs and storm debris when a heavier grapple is not required.

In these scenarios, a Sorting Grapple helps raise recovery rates and makes trucks load faster, which directly shortens project timelines.

Excavator Grapple Attachment: Technical Specs And Compatibility

Choosing an Excavator Grapple Attachment starts with matching the tool to the carrier. The right fit keeps the machine stable and efficient.

Typical specifications and options:

- Excavator Range: 5–50 t carrier weight classes.

- Jaw Opening & Width: Sized to your most common material (e.g., large slabs vs. mixed debris).

- Working Pressure / Flow: Tuned to your hydraulic circuit; optional flow control valves.

- Rotation Type: Free (non-rotating) or 360° hydraulic rotator with swivel joint.

- Tooth and Edge Options: Bolt-on wear teeth, serrated edges, or smooth edges for specific materials.

- Mounting: Direct pin-on, dedicated hanger, or quick coupler compatible.

- Weight Balance: The Center of gravity is designed to keep the boom stable at reach.

A well-matched Excavator Grapple Attachment protects the boom and stick, avoids overloading, and keeps cycle times quick.

Excavator Demolition Grapple: Advantages Versus Standard Grapples

An Excavator Demolition Grapple is engineered for impact, abrasion, and irregular loads. Compared with a standard utility grapple or bucket-type grab, users typically see:

- Longer Wear Life: Q355/NM400 structure and replaceable wear parts extend service life on abrasive materials.

- Higher Throughput: Wider jaws and rotation help increase picks per hour; field users report 15–30% faster loading.

- Less Downtime: Protected hoses, strong pins, and accessible grease points reduce unplanned stops.

- Better Safety: Reliable twin-cylinder clamping reduces dropped loads, improving crew safety around the machine.

These gains mean fewer passes, fewer machine moves, and more productive hours each shift.

Application Scenarios In Detail

Demolition sites vary, but the grapple’s job is constant—grab, sort, and load quickly.

- Urban Teardowns: Rotate to pick, swing, and drop into trucks without repositioning the excavator.

- Industrial Demolition: Strong tips dig under slabs; wide opening grips bulky sections.

- Recycling Centers: Sort mixed loads into clean streams to raise resale value.

- Storm Cleanup / Forestry (Optional): Move logs and timber with serrated edges for a firm hold.

When paired with crushers, shears, or magnets, the grapple becomes the central “feeder,” keeping the line moving at a steady pace.

Customer Case: European Demolition Contractor Feedback

A Northern European contractor upgraded two 22-ton excavators with rotating grapples. The crew reported:

- Faster Sorting: About 25% quicker loading of mixed rubble versus their old non-rotating grab.

- Cleaner Loads: Rotation allowed precise picking, so trucks arrived at the recycler with less contamination.

- Lower Costs: Fewer hose failures after switching to protected routing; less downtime during peak season.

“Jaw control is excellent. Rotation lets us place concrete and rebar exactly where it should go. Our operators prefer this tool because it saves moves and keeps the site tidy.”

Photos and videos from the site show steady handling of concrete blocks and twisted rebar, even at full reach.

Packaging And Transportation

YG prepares each grapple for safe global delivery.

- Export-Ready Crating: Standard wooden cases or steel-frame pallets with moisture protection.

- Transport Options: Sea freight as standard; rail options available for inland routes.

- Compliance: Export paperwork and CE-conformity documents supplied as needed.

- Pre-Shipment Tests: Functional checks for cylinders, rotation, and valve integrity before packing.

Clear labels and a parts list help your team receive and install the attachment without delays.

After-Sales And Service

Strong support keeps productivity high from day one.

- Install Guides: Step-by-step videos and mounting drawings for your carrier and coupler type.

- Warranty: 1-year warranty; wearing parts and a seal kit are shipped with the tool.

- Global Parts Supply: Pins, bushes, teeth, rotator parts, and hoses available for quick dispatch.

- Technical Support: Hydraulic setup advice (pressure/flow), rotation tuning, and troubleshooting.

Service emails and messaging channels connect you quickly with a technician for real-time help.

Choosing The Right Demolition Grapple For Excavator Tonnage

Match the tool to the carrier for the best balance of speed and stability. For a 14–18 t excavator, pick a mid-weight grapple with a strong jaw opening; for 30–50 t machines, use heavy frames and larger rotators. Always align hydraulic flow and pressure with manufacturer specs to protect seals and maintain clamping force.

Parts And Customization Paths

Projects differ; the tool should match your material mix.

- Jaw Profiles: Narrow tips for penetration; wide pads for bulky debris.

- Edges and Teeth: Bolt-on teeth for aggressive bite; smooth edges for sorting.

- Rotation Package: Non-rotating for budget builds; 360° with swivel for precision work.

- Interface: Pin-on, dedicated hanger, or quick coupler setup to suit your fleet.

- Finish: High-visibility paint with your logo for brand presence on site.

These options help teams get the exact performance they need without overspending.

Ready to boost your demolition efficiency? Contact YG for a free quote on our Demolition Grapple for Excavator and get your custom solution today!

WhatsApp/WeChat/Phone: 86 138 3715 9132