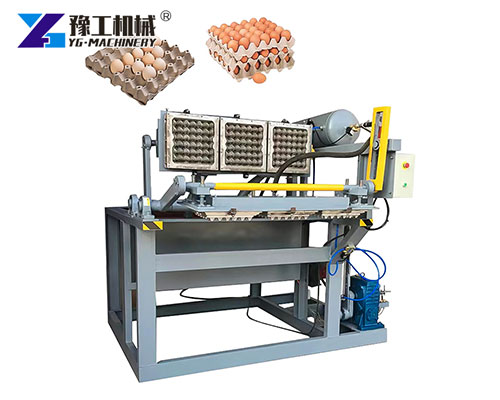

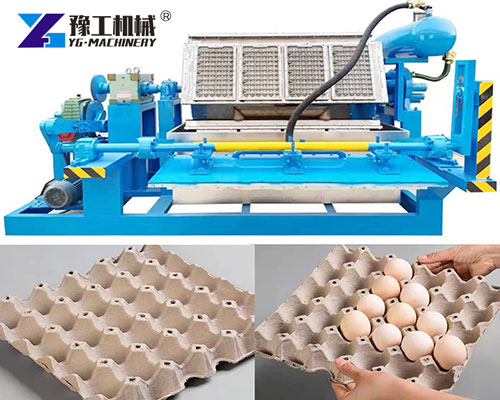

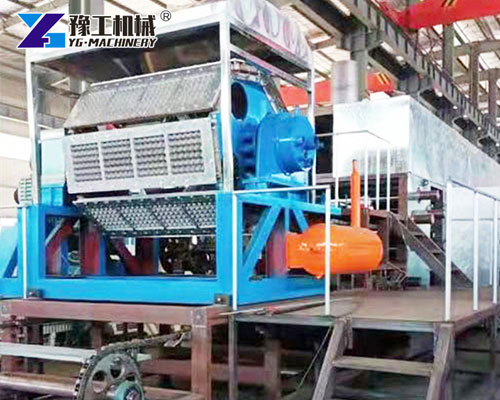

Egg tray machine, also known as an egg tray making machine or egg tray forming machine, is a piece of equipment designed to produce egg trays. These machines are crucial for the egg packaging industry. They transform raw materials into various types of egg trays that can safely store and transport eggs.

There are different types of egg tray machines, including small egg tray making machines suitable for small-scale businesses and automatic egg tray molding machines for large-scale production. WhatsApp/WeChat/Phone: 86 138 3715 9132

Egg Carton Making Machine Parameters

| Model | YG-1*3 | YG-1*4 | YG-3*4 | YG-4*4 | YG-4*8 | YG-5*8 | YG-6*8 |

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kW) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

Application of Egg Tray Machine

- Egg Farming: Egg farmers need a large number of egg trays to pack their freshly laid eggs. The egg trays protect the eggs from damage during storage and transportation, ensuring that the eggs reach the market in good condition.

- Supermarkets and Retail Stores: These places sell eggs in large quantities. Egg trays are essential for displaying eggs neatly on the shelves and protecting them from being crushed.

- Food Processing Plants: Plants that use eggs as raw materials for food production also require egg trays for egg storage and handling.

Working Process of Egg Forming Tray Machine

- Raw Material Preparation: The raw materials, such as waste paper, are collected and shredded. They are mixed with water to form a pulp.

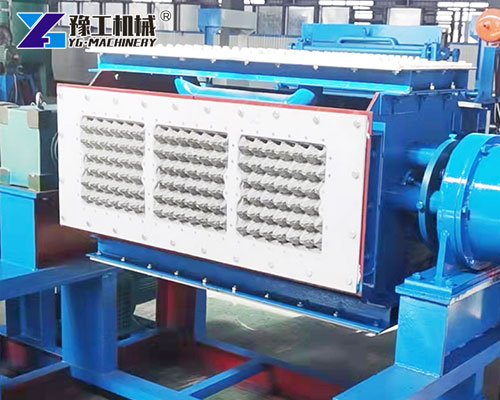

- Forming: The pulp is pumped into the egg tray forming machine. The machine uses molds to form the pulp into the desired egg tray shape. The excess water is drained during this process.

- Drying: After forming, the wet egg trays are transferred to a drying area. This can be a natural drying process in the sun or an artificial drying process using a dryer in the machine.

- Stacking and packing: Once the egg trays are dry, they are stacked and packaged for storage or transportation.

Main Raw Materials Used

The paper egg tray making machine mainly uses the following raw materials:

- Waste Paper: Newspaper, cardboard, and other types of waste paper are commonly used. There are a lot of these materials, and they don’t cost a lot of money. This makes them perfect for making egg trays.

- Water: Water is used to mix with the waste paper to form the pulp. Water is a crucial part of the production process.

- Additives: Sometimes, manufacturers add additives such as sizing agents and strengthening agents to improve the quality of the egg trays, making them more durable and water-resistant.

Products Generated

The egg tray molding machine can produce a variety of products:

- Egg Trays: The most common product. They come in different sizes and designs, such as 30-egg trays, 12-egg trays, etc., to meet different market demands.

- Egg Cartons: Similar to egg trays but with a more enclosed structure, providing better protection for eggs.

- Fruit Trays: You can also adjust some egg tray molding machines to produce fruit trays, and people use these trays to pack fruits such as strawberries, cherries, etc.

Advantages of Egg Tray Machine

- Environmentally Friendly: The machine helps to recycle waste and reduce environmental pollution by using waste paper as a raw material.

- Cost-effective: The raw materials are inexpensive and readily available. The production cost of egg trays is relatively low, which can generate significant economic benefits for manufacturers.

- High efficiency: Automatic egg tray making machines can produce a large number of egg trays in a short time, improving production efficiency.

- Customization: Operators can adjust the machines to produce egg trays of different sizes and shapes according to the customer’s requirements.

How Much is the Egg Tray Machine Price?

- Machine Type: Small egg tray machines are typically more affordable than automatic egg tray molding machines. These machines suit small-scale production well, and manufacturers typically price them in the range of a few thousand dollars. In contrast, automatic machines with advanced features and high production capacity can cost tens of thousands of dollars.

- Production Capacity: Machines with higher production capacity tend to be more expensive. If your production needs exceed a certain level, investing in a more expensive machine might be necessary.

- Quality: Well-known brands and machines with a reputation for quality often come with a higher price tag. However, people often associate them with superior after-sales service and more reliable performance.

Paper Egg Tray Manufacturer – YG Machinery

YG Machinery is a leading manufacturer of high-quality egg tray machines, renowned for combining advanced technology with durable materials to deliver efficient, long-lasting solutions. Their machines cater to diverse needs, offering customizable options for production capacity, tray sizes, and design specifications. Beyond robust performance, YG prioritizes customer satisfaction with comprehensive after-sales support, including on-site installation, operator training, and prompt maintenance services. Whether you’re a small farm or a large-scale producer, YG ensures seamless operation and timely troubleshooting, empowering businesses to maximize productivity while minimizing downtime. WhatsApp/WeChat/Phone: 86 138 3715 9132