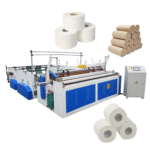

A Toilet Paper Rewinding Machine plays a key role in turning jumbo tissue paper into finished toilet rolls ready for sale. For manufacturers, this machine directly affects daily output, roll quality, and labor cost. Whether supplying retail supermarkets or wholesale markets, a stable and efficient rewinder helps factories stay competitive and control production costs.

YG provides practical tissue rewinding solutions designed for real production needs, not just machine specifications.

What Is A Toilet Paper Rewinding Machine

A Toilet Paper Rewinding Machine is a core unit in a toilet paper production line. Its main task is to rewind large jumbo rolls into smaller toilet paper rolls with fixed length, tight structure, and clean perforation.

Core Role In A Toilet Paper Production Line

In a complete toilet paper line, the rewinding machine connects upstream and downstream equipment:

- Works after jumbo roll slitting or unwinding

- Controls roll length, diameter, and tightness

- Prepares rolls for final packaging

Without a stable rewinder, even high-quality paper material cannot become a sellable product.

Connection With Other Equipment

The rewinding machine works closely with:

- Slitting machines that prepare jumbo rolls

- Embossing units that improve softness and appearance

- Packing machines that wrap finished toilet rolls

A balanced setup between these machines ensures smooth and continuous production.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Toilet Paper Rewinding Machine Parameter

| Finished roll diameter | 40-200mm |

| Paper Weight | 13-18gsm single layer |

| Jumbo Roll Width | Max 2200mm |

| Jumbo Roll Diameter | Max φ1200mm |

| Paper Core Inner Diameter | 76.2mm |

| Speed | 150-280m/min |

| Host Power | 380V/50HZ/3PH, 5.5kw |

| Weight | 2800kg |

| Dimensions | 6500x3650x1750mm |

How A Toilet Paper Rewinding Machine Works

The working process of a Toilet Paper Rewinding Machine follows clear and repeatable steps that help keep product quality stable.

Standard Working Process

The typical process includes:

- Jumbo paper loading onto the unwind stand

- Paper rewinding under controlled tension

- Perforation at fixed distances

- Automatic cutting into finished rolls

Each step affects roll appearance, tearing quality, and user experience.

Automatic Vs Semi-Automatic Workflow

An automatic tissue rewinding machine uses PLC control to manage speed, roll length, and cutting. It reduces manual work and improves efficiency.

A semi-automatic model requires more operator involvement but offers lower investment cost and simpler operation for smaller factories.

Key Benefits For Toilet Paper Manufacturers

Using a professional Toilet Paper Rewinding Machine brings clear benefits for manufacturers at different stages.

Production And Cost Advantages

Key advantages include:

- Higher daily output with stable speed

- Lower labor cost per roll

- Reduced paper waste during rewinding

These benefits help factories improve profit margins over time.

Consistent Roll Quality For Different Markets

A stable toilet paper roll-making machine ensures:

- Uniform roll diameter

- Accurate paper length

- Clean perforation for easy tearing

This consistency is important for both retail brands and bulk wholesale buyers.

Main Types Of Toilet Paper Rewinding Machines

Different factories need different machine types based on output and budget.

Semi-Automatic Rewinding Machine

This type is suitable for:

- Small or startup factories

- Limited production volume

- Lower initial investment

It offers a simple structure and easy maintenance.

Fully Automatic Toilet Paper Rewinding Machine

Fully automatic models are ideal for:

- Medium to large factories

- Continuous production needs

- Lower long-term labor dependency

They are often chosen when upgrading a toilet paper machine line.

High-Speed Models Vs Entry-Level Models

High-speed machines focus on output and efficiency, while entry-level machines focus on cost control and basic functionality.

Technical Features That Affect Production Quality

Machine design details directly influence final product quality.

Key Technical Points

Important features include:

- Stable rewinding tension control

- Accurate perforation system

- Durable cutting blade structure

- PLC system for easy parameter adjustment

These features help maintain stable production even during long working hours.

How To Choose The Right Toilet Paper Rewinder

Selecting the right machine requires matching equipment with real production conditions.

Key Selection Factors

Manufacturers should consider:

- Required capacity in rolls per minute

- Jumbo roll width and paper core size

- Available factory space and worker skill level

- Future production expansion plans

A well-matched toilet tissue rewinder prevents wasted investment and reduces the need for frequent adjustments.

When A Toilet Paper Rewinding Machine Is NOT Recommended

Although widely used, a Toilet Paper Rewinding Machine is not suitable for all situations.

It may not be ideal for:

- Tiny home workshops with low daily output

- Projects using non-standard or experimental paper materials

- Handmade paper products that do not require uniform rolls

In these cases, simpler or manual solutions may be more practical.

Applications And Typical Customers

A toilet paper machine, like a rewinder, is commonly used by:

- Small and medium-sized toilet paper factories

- New investors are building a tissue production line

- OEM paper product manufacturers

- Export-oriented tissue suppliers

It supports both local sales and international distribution.

Why Choose A Reliable Toilet Paper Rewinding Machine Supplier

Machine performance depends not only on design but also on supplier support.

Long-Term Value Factors

A reliable supplier offers:

- Stable machine structure and long service life

- Easy access to spare parts and wear components

- Custom solutions for different production needs

YG focuses on practical design, stable operation, and long-term support to help customers grow steadily.