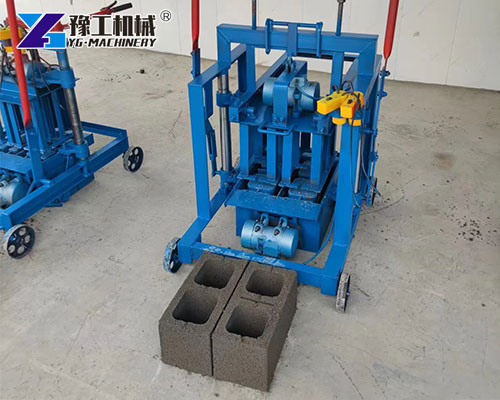

The Small Mobile Brick Machine is a compact, portable device used to manufacture bricks for construction, particularly in small-scale or remote operations. Unlike traditional large brick-making machinery that requires significant space and infrastructure, a mobile brick machine is designed for ease of use and transportation, offering flexibility for on-site production. These machines are ideal for producing clay bricks, cement bricks, and other types of blocks directly at construction sites, significantly reducing transportation costs and material waste. WhatsApp/WeChat/Phone +86 138 3715 9132

Parameters of Small Mobile Brick Machine for Sale

| Molding cycle(s) | 455 |

| Equipped with power(kw) | 1.1 |

| Production capacity per shift (pieces) | Standard bricks 240*53*115mm 3600 pieces Hollow bricks 390*190*190mm 600 pieces |

| Overall size | Length 900*Width 700*Height 1100 |

| The weight | 200kg |

| Number of operators | 1-2 people |

How Does a Small Moving Brick Machine Work?

The operation of a small moving brick machine involves several key stages:

- Feeding Raw Material:

- The raw materials (typically cement, sand, or clay) are loaded into the machine’s hopper or mixing chamber.

- Mixing and Preparation:

- Some mobile brick machines come with a mixer that blends the raw materials into a uniform mixture. In other cases, pre-mixed material can be fed directly into the mold.

- Molding and Compression:

- The raw material is then fed into molds or brick cavities where it is compressed under hydraulic pressure to form the desired shape.

- The compression ensures that the bricks are firm and of consistent quality.

- Curing and Drying:

- After molding the bricks, you may need to let them cure or dry. Depending on the material used, you can dry them naturally by air-drying or in controlled environments (e.g., drying chambers).

- Demolding:

- Once the bricks have set, the mold is removed, and the finished bricks are ready for stacking and curing.

- Transporting and Storing:

- Their mobility enables you to move these machines to various areas of a construction site, facilitating the direct production of bricks where needed.

Features of Mobile Brick Machine

- Mobility: As the name suggests, the most prominent feature of a Small Mobile Brick Machine is its mobility. With wheels or a compact design, Mobile Brick Maker models can be easily transported to different job sites. This eliminates the need to transport heavy bricks over long distances, saving both time and money.

- Compact Size: These machines are designed to be small and lightweight without sacrificing functionality. The Mobile Block Machine variants can fit into tight spaces, making them suitable for construction projects in urban areas or locations with limited access.

- Versatility: Small mobile brick machines can produce various types of bricks and blocks. You can adjust them to create different shapes, sizes, and even textures, enabling you to meet the specific requirements of your project.

- Low Energy Consumption: Electric Mobile Brick Machine models are engineered to consume less energy. The efficient electric motors and optimized mechanical designs ensure that you can produce bricks without incurring high electricity costs.

Advantages of Small Brick Machine

- Cost-Effective: By producing bricks on-site, you can reduce transportation costs associated with buying pre-made bricks. Additionally, the relatively low purchase price of small mobile brick machines, especially semi-automatic models, makes them an affordable investment for small-scale projects.

- Customization: You have the freedom to customize the bricks according to your project’s needs. Whether it’s adjusting the size for a unique architectural design or changing the color by adding pigments to the mixture, a Small Mobile Brick Machine gives you the flexibility to create the perfect bricks.

- Quick Production: Even the semi-automatic models can produce a significant number of bricks in a short period. For urgent projects, this means you can meet deadlines without relying on external brick suppliers.

Applications of Small Mobile Brick Machines

- Construction:

- The construction industry primarily uses small mobile brick machines to produce bricks on-site. This practice reduces transportation costs and enables the production of fresh bricks precisely where they are required.

- Ideal for building houses, walls, foundations, and other structures in areas with limited access to large brick factories.

- Small-Scale Brick Manufacturing:

- Entrepreneurs and small businesses can invest in these machines to start a local brick-making business. This machine allows for the production of various types of bricks in small quantities without the need for a large factory setup.

- Paving and Road Work:

- These machines can produce paving stones and bricks for road construction, paths, and walkways. The portability of the machine makes it ideal for producing paving bricks directly on-site.

- Eco-Friendly Building Projects:

- Mobile brick machines that use biodegradable materials or recycled aggregates for brick production are being increasingly used in sustainable construction projects.

How to Choose a Small Mobile Brick Making Machine

- Production Requirements: Consider the volume of bricks you need to produce. If you have a large-scale project, an automatic Small Mobile Brick Machine would be more suitable. For smaller projects, a semi-automatic model can meet your needs while keeping costs down.

- Type of Bricks: Determine the types of bricks or blocks you want to produce. Make sure the machine you choose can handle the specific shapes, sizes, and textures you require. Some machines may be more suitable for solid bricks, while others can produce hollow or interlocking blocks.

- Budget: Set a budget for your brick – making machine. Keep in mind that while automatic machines offer more features and higher productivity, they also come at a higher price. Evaluate the long – term costs, including maintenance and energy consumption, in addition to the initial purchase price.

- Mobility Needs: If you need to move the machine frequently between different job sites, look for a more portable option. You should consider factors such as the weight of the machine, the type of wheels, and the ease with which it can be loaded onto a truck.

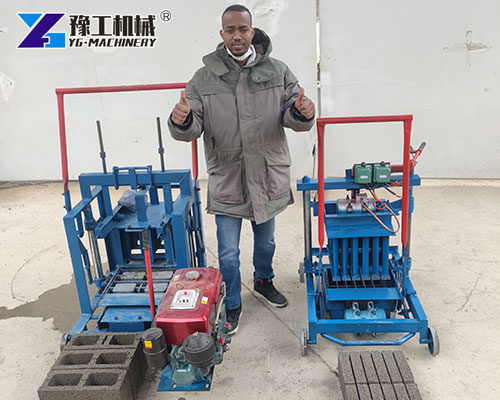

- After – Sales Service: Choose a manufacturer like YG that offers excellent after – sales service. This includes technical support, availability of spare parts, and training for your operators. A reliable after – sales service can ensure the smooth operation of your machine and minimize downtime.

YG Small Mobile Brick Machine Manufacturer

YG stands out as a leading manufacturer of Small Mobile Brick machines for several reasons. We offer a wide range of models, from Automatic Small Mobile Brick Machine to Semi-Automatic Small Mobile Brick Machine, as well as various types such as block machine and cement brick machine, to meet the diverse needs of our customers.

WhatsApp/WeChat/Phone +86 138 3715 9132