The Pipe Bending Machine is a piece of equipment used to bend pipes into various shapes and angles. It plays a crucial role in many industries, such as construction, automotive, and manufacturing. These machines can handle different types of pipes, including steel, aluminum, and copper, and are designed to meet specific bending requirements. WhatsApp/WeChat/Phone +86 138 3715 9132

Parameters of the Steel Pipe Bending Machine for Sale

| Model | YG-38 | YG-51 | YG-76 |

| Steel pipe dia.(mm) | 38 | 51 | 76 |

| Pipe thickness(mm) | 2 | 2-3.5 | 44656 |

| Bending angle Qty | 9 | 9 | 9 |

| Max. angle | 180 | 180 | 180 |

| Min. angle | 30 | 30 | 30 |

| Voltage(v) | 380 | 380 | 380 |

| Dimension(mm) | 920*650*850 | 920*680*850 | 1150*700*1000 |

| Weight(kg) | 210 | 260 | 420 |

Working Principle of Pipe Bender Machine

The working principle of a pipe bending machine is based on applying force to the pipe at a specific point.

There are generally two main methods: roll bending and press bending.

In roll bending, the pipe passes through a set of rollers that gradually bend it to the desired shape. Press bending, on the other hand, uses a hydraulic or mechanical press to apply force to the pipe at a single point, causing it to bend.

CNC pipe bending machines use computer programs to control the bending process, ensuring high precision and repeatability.

Applications of Pipe Bending Machines

- Construction & Architecture: For handrails, frames, and piping infrastructure.

- Automotive Industry: Bending exhaust systems, roll cages, fuel lines.

- HVAC and Plumbing: For bending pipes used in heating, ventilation, and plumbing systems.

- Shipbuilding & Aerospace: Precision bends for lightweight tubing and complex layouts.

- Furniture & Interior Design: Creating sleek metal frames, art pieces, and fixtures.

- Agricultural Equipment: Bending structural steel tubes for machinery and tools.

Features of Pipe Bender Machines

Precision & Consistency

Equipped with digital angle control and CNC automation, they achieve accurate bends to strict specifications, ensuring repeatable results with programmable settings.

Wide Material & Size Adaptability

Handle diverse pipe diameters, wall thicknesses, and materials (steel, aluminum, plastic) via multi-radius capability and durable, interchangeable die sets.

Automation & Ease of Use

Automated features like touchscreen interfaces and button controls streamline operation, reducing labor costs while enhancing productivity—ideal for both simple and complex bending tasks.

Durability & Safety

Built with high-quality materials and reinforced components to withstand heavy use, they include safety mechanisms (emergency stops, overload protection) and modular/compact designs for space-efficient workshops.

Flexible Design Options

Offer compact layouts for limited spaces or expandable modular systems for large-scale industrial environments, balancing portability with heavy-duty performance.

Types of Tube Pipe Bending Machine

- Hydraulic Pipe Benders: Use hydraulic power for heavy-duty bending of thick-walled pipes, ideal for industrial applications requiring high force.

- CNC Pipe Bending Machines: Fully automated with programmable precision, suited for complex, high-volume manufacturing and accuracy-critical industries.

- Electric Pipe Benders: Offer speed and precision for medium-scale tasks, balancing efficiency and ease of use.

- Portable Pipe Benders: Lightweight and mobile, perfect for on-site installations, repairs, or limited-space environments.

- Mandrel Bending Machines: Prevent deformation in thin-walled pipes, commonly used in aerospace, automotive, and HVAC for delicate materials.

Advantages of Using a Tubing Bender Machine

- Consistent Accuracy: Perfect bends every time, even in large batches.

- Reduced Waste: Minimizes cutting errors and leftover scrap.

- Enhanced Design Freedom: Supports custom angles and spiral, compound bends.

- Increased Speed: Especially with CNC and hydraulic machines.

- Improved Safety: Less manual force, reducing strain and injury risk.

- Adaptability: Works with different metals, shapes (round, square), and sizes.

Maintenance of Pipe Bending Machine

Regular maintenance is essential for the proper functioning and longevity of a pipe-bending machine. Here are some maintenance tips:

Cleaning: Keep the machine clean from dirt, debris, and metal shavings. Regularly wipe down the surfaces and clean the bending dies.

Lubrication: Lubricate the moving parts, such as the hydraulic cylinders and bearings, according to the manufacturer’s recommendations. This helps reduce friction and wear.

Inspection: Regularly inspect the machine for any signs of damage, such as cracks, leaks, or loose parts. Replace any worn – out components promptly.

How to Choose a Pipe Bending Machine

Consider these key factors to select the right pipe bender:

Material & Pipe Specs: Match the machine’s capacity for pipe diameter, wall thickness, and material (steel, aluminum, etc.). Hydraulic/CNC suits heavy-duty materials; electric works for lighter tasks.

Bend Requirements: Ensure the machine can achieve the needed angle, radius, and complexity—programmable CNC models excel in intricate designs.

Production Volume: Opt for automated CNC machines for high-volume manufacturing; manual/hydraulic for occasional small projects.

Space & Mobility: Choose compact/portable units for on-site work or limited spaces; industrial models for fixed workshops.

Budget & ROI: Balance upfront costs with long-term maintenance, energy efficiency, and durability to maximize value.

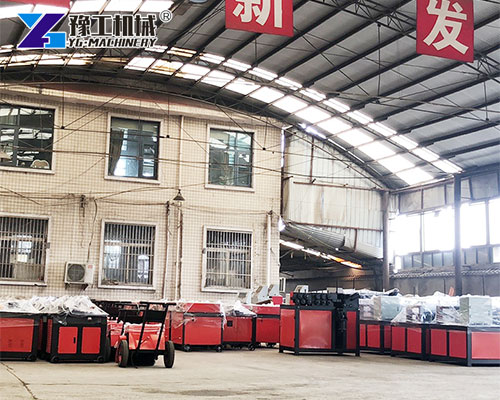

Pipe Bending Manufacturer – YG Machinery

YG is a well-known manufacturer of pipe-bending machines. They have years of experience in the industry and are committed to producing high-quality machines. Pipe bending machines are known for their precision, reliability, and durability. They offer a wide range of models to meet different customer needs, from small-scale manual benders to large-scale CNC pipe bending machines. With a focus on innovation and customer satisfaction, YG has established a good reputation in the market. If you are choosing a pipe-bending machine, please contact us now! WhatsApp/WeChat/Phone +86 138 3715 9132