The hydraulic rock splitter is a non-explosive, quiet, and dust-free method for breaking large rocks and concrete structures. It’s designed for environments where traditional blasting methods are unsafe or restricted, such as urban areas, tunnels, or near sensitive structures. Using hydraulic pressure, the splitter creates a force that breaks rock with precision and minimal disturbance.

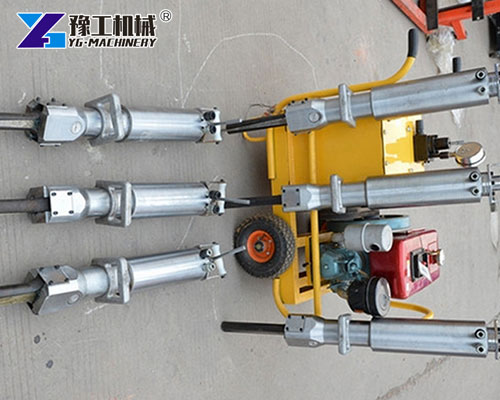

YG offers highly reliable and efficient rock splitters that are easy to operate and suitable for a variety of construction and demolition applications.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Hydraulic Rock Splitter Parameter:

| Model | YG-250 | YG-350 | YG-450 |

| Power | Diesel Power Pack | ||

| Diesel Power Pack | Changchai 6hp or 8hp | ||

| Hydraulic Power Unit | Pressure Adjustable 10-60Mpa | ||

| Splitter Length (mm) | 1000 | 1100 | 1200 |

| Wedge Length (mm) | 250 | 350 | 450 |

| Wedge Weight (kg) | 30 | 36 | 43 |

| Piston Stroke (mm) | 90/220 | 90/220 | 90/220 |

| Drilling Depth (mm) | >500 | >700 | >900 |

| Drilling Diameter (mm) | 42 | 50 | 55 |

| Crack Width (mm) | 10-20 | 10-20 | 10-20 |

| Splitting Time (s) | 10-15 | 10-15 | 10-15 |

| Splitting Force (T) | 800 | 900 | 1000 |

Key Features Of Hydraulic Rock Splitter

When manufacturing YG’s rock splitter models, we prioritize durability and safety. We design these models for operators who require high precision, low noise, and low vibration performance in challenging environments.

High splitting force, capable of splitting hard rock and reinforced concrete

Quiet operation, suitable for noise-sensitive areas

Compact and portable design, easy to handle and move

No flying debris, reducing risk during operation

Easy maintenance and long service life

Multiple wedge sizes are available for different material thicknesses

Advantages Of Using A Hydraulic Rock Splitter

- Safe and silent: No vibrations, flying debris, or risk of explosion

- Environmentally friendly: No dust or toxic emissions

- Cost-effective: Lower labor and maintenance costs

- Precise breaking: Controlled splitting prevents overbreak and structure damage

- Versatile: Can be used vertically or horizontally, depending on the site requirement

- Minimal prep work: No heavy setup or extensive safety barriers needed

These advantages make rock splitters an ideal solution for modern construction and mining demands.

Concrete Splitter: Breaking Concrete Without Blasting

A concrete splitter is a type of rock splitter that focuses on breaking reinforced concrete in buildings, bridges, and pavements. Contractors or workers find it ideal for selective demolition when they must preserve the structural integrity in surrounding areas.

Applications include:

- Demolishing old concrete floors and columns

- Removing reinforced concrete walls

- Creating expansion joints in tunnels and subways

- Controlled breaking in chemical plants or nuclear facilities

In all cases, the splitter delivers a clean, controlled break with minimal noise and no dust pollution, making it suitable for residential and industrial sites alike.

Applications Of Rock Splitting Equipment

Workers can use the rock splitting equipment in a wide range of fields. Its versatility makes it indispensable in various industries where traditional methods are limited or unsafe.

- Mining and quarrying: Breaking boulders and extracting large stone blocks

- Urban demolition: Safe concrete removal without damaging nearby structures

- Tunnel excavation: Controlled rock breaking in confined underground spaces

- Road and bridge construction: Removing old concrete for repair and rebuilding

- Foundation work: Breaking through tough bedrock in high-rise projects

These applications show how this equipment supports projects that require silent, safe, and clean operations.

Working Principle Of A Hydraulic Rock Splitter

The working principle of a hydraulic rock splitter is based on hydraulic pressure applied to a wedge inserted into a pre-drilled hole. The force expands the wedge, applying outward pressure until the rock or concrete splits.

- Drill a hole in the material to be split (typically 90mm diameter, 400–800mm deep)

- Insert the hydraulic wedge block into the hole

- Apply hydraulic pressure via a power unit

- The wedge expands, creating stress that fractures the material

- Repeat the process in a sequence to complete the break

This method ensures precision with no vibration, ideal for tight or regulated job sites.

Why Choose YG Machinery To Buy A Hydraulic Rock Splitter

YG Machinery is a trusted supplier of hydraulic rock splitter equipment, offering durable, efficient, and competitively priced models to meet different project needs. Whether you’re dealing with hard rock, reinforced concrete, or need a concrete splitter for precision demolition, YG offers dependable machines built to perform in the most demanding environments.

WhatsApp/WeChat/Phone: 86 138 3715 9132