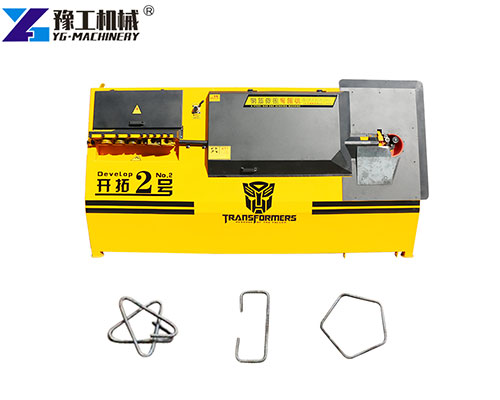

The CNC Steel Bar Bending Machine is an advanced piece of equipment designed to bend steel bars accurately according to preset parameters. This technology replaces the traditional manual bending methods, which are often time-consuming and less accurate. The Machine can handle different diameters and types of steel bars, making it a versatile tool in the construction and manufacturing industries.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of CNC Steel Bar Bending Machine

| Model | YG-1 | YG-2 |

| Single wire | Round steel 4-10mm Deformed steel bar 4-8mm | Round steel 4-12mm Deformed steel bar 4-10mm |

| Double wire | Round steel 4-6mm Deformed steel bar 4-6mm | Round steel 4-8mm Deformed steel bar 4- 8 mm |

| Max bending angle | ±180° | ±180° |

| Center pin diameter | 16、18、20 | 16、18、20 |

| Maximum towing speed | 60m/min | 60m/min |

| Maximum bending speed | 800°/sec | 800°/sec |

| Machine size | 2600*800*1700mm | 3280*1000*1700mm |

| Pieces Processed | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa |

| Total Power | 14kw | 20kw |

| Working temperature | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° |

| Average power | 4.5KW/h | 5KW/h |

| Total weight | 1150KG | 1350KG |

Applications of CNC Rebar Bending Machine for Sale

The CNC Rebar Bending Machine demonstrates exceptional versatility across multiple industries, offering precision bending solutions for steel reinforcement bars (rebar) and metal components. Its computer-controlled operation ensures structural accuracy and production efficiency in key sectors

1. Construction Industry Applications

- Reinforced Concrete Structures: Essential for bending rebar in high-rise buildings, bridges, and tunnels. Produces critical components like stirrups, hoops, and bent-up bars to enhance structural integrity against environmental stresses (wind, seismic forces).

- Infrastructure Projects: Creates customized reinforcement shapes for foundations, columns, and beams, ensuring compliance with engineering specifications.

2. Manufacturing Sector Applications

- Automotive Industry: Shapes precision components for vehicle frames and chassis with complex geometries.

- Metal Fabrication: Produces steel furniture, industrial machinery parts, and architectural elements like decorative fences.

- Custom Components: Enables mass production of specialized brackets, supports, and connection elements.

5 Features of CNC Steel Bar Bending Machine

CNC Rebar Bending Machines combine precision (±0.1° accuracy) and efficiency through advanced CNC systems, enabling multi-bar simultaneous bending for rapid production. Key features include:

- High Precision: Automated angle/length control with ±1mm tolerance ensures compliance with strict standards.

- Enhanced Productivity: Processes 5- 10x faster than manual methods, supporting continuous heavy-duty operation.

- User-Friendly Interface: Intuitive programming for bending parameters (angle, diameter, radius), reducing skill requirements.

- Cost Efficiency: Competitive pricing balances initial investment with long-term gains in labor/time savings.

- Robust Construction: Industrial-grade materials ensure durability in demanding environments.

CNC Steel Bar Hoop Bending Machine

The CNC steel bar hoop bending machine is a specialized type of CNC Steel Bar Bending Machine. It is designed specifically for bending steel bars into hoops or stirrups. These hoops are commonly used in reinforced concrete structures to provide additional strength and stability.

This machine has unique features such as a special bending mechanism that can form hoops of different diameters and shapes. It can also handle different types of steel bars, including high-strength steel. The CNC Steel Bar Hoop Bending Machine is very efficient in producing large quantities of hoops, which are essential for large-scale construction projects.

How to Use a CNC Rebar Bending Machine

Using a CNC Steel bar-bending machine is relatively straightforward. First, the operator needs to input the bending parameters into the CNC system. These parameters include the bending angle, length, and diameter of the steel bar. Next, the steel bar is loaded onto the machine. The machine will then automatically feed the bar to the bending mechanism.

During the bending process, the operator should monitor the machine to ensure that everything is working properly. After the bending is complete, the bent steel bar can be removed from the machine. It’s important to follow the safety instructions provided by the manufacturer to avoid any accidents.

How to Choose a CNC Steel Bar Bending Machine

Bending Specifications

- Match machine capacity to your project needs:

- Max bar diameter (6-50mm)

- Length (up to 12m)

- Angle range (0-180°)

Precision & Tech

- Prioritize ±0.1° accuracy via CNC systems and servo motors for critical reinforcement work.

Speed

- Opt for 800-1,500 bends/hour models for large-scale projects.

Durability

- Select heavy-duty frames (cast iron/steel) and industrial-grade components.

Specialized Needs

- For stirrup production, choose integrated Automatic Stirrup Bending Machines to reduce secondary processing.

YG CNC Steel Bar Bending Machine Advantage

YG Machinery excels in delivering CNC Steel Bar Bending Machines that combine precision engineering and cost efficiency. Our machines feature:

- Premium Durability: Built with high-grade materials and advanced technology, ensuring ±0.1° bending accuracy and robust performance in heavy-duty operations.

- Customized Options: Diverse models accommodate projects of all scales, from small workshops to industrial enterprises.

- Competitive Pricing: CNC Rebar Bending Machine Price balances affordability with industry-leading quality, maximizing ROI.

- Comprehensive Support: 24/7 technical assistance, rapid spare parts delivery, and maintenance services to minimize downtime.

- Innovation-Driven: Continuous R&D upgrades adapt to evolving market demands, enhancing automation and energy efficiency.

WhatsApp/WeChat/Phone: 86 138 3715 9132