The napkin paper machine efficiently manufactures soft, durable paper napkins in various sizes and designs via automated embossing, folding, and cutting. Available as fully automatic models, it meets high demand in households, restaurants, and commercial spaces. Ideal for sanitary napkin production—including facial tissues and wet wipes—it offers high-speed output and easy customization, making it a smart investment for the paper product industry. Contact us to start your napkin production line!

WhatsApp/WeChat/Phone: 86 138 3715 9132

Napkin Paper Machine Parameter

| Roller surface length | 1080/1270/1480/1780/2100 (mm) |

| Effective length | 1060/1250/1460/1750/2080 (mm) |

| Fan power | 15/15/18.5/18.5/22 (kW) |

| Motor power | 3/4/4/5.5/7.5 (kW) |

| Folding speed | 500-1000 sheets/minute/row |

| Diameter of base paper | ≤1200 (mm) |

| Diameter of the original paper core | 3 “(76.2 mm) |

| Power supply | 380V/50Hz |

Features of Napkin Paper Machine

- High Efficiency: Automatic models, equipped with advanced motors and intelligent controls, enable rapid, continuous production—some output hundreds of napkins per minute, significantly boosting factory productivity.

- Customization : Adjustable settings allow tailoring napkin size, thickness, and folding styles (e.g., cocktail to dinner napkins) to meet diverse commercial or household needs.

- Consistent Quality: Precision cutting and folding mechanisms ensure clean edges and uniform folds, while durable components maintain stable production for soft, reliable napkins.

- Low Maintenance: User-friendly designs with accessible parts and clear guidelines simplify upkeep. Regular cleaning and basic inspections minimize downtime and costs, ensuring smooth operation.

Working Process of Napkin Paper Machine

- Raw Material Feeding

Feed the raw paper material into the machine. The paper rolls are usually placed on a holder at the beginning of the Napkin Paper Machine Line. The machine then pulls the paper through the various processing units. - Cutting

Once the paper is fed, the cutting unit of the machine cuts the paper into the desired size. The cutting blades are sharp and can make precise cuts, ensuring that each napkin has a uniform size. - Folding

After cutting, the paper pieces are sent to the folding unit. Different folding patterns can be achieved depending on the machine settings.For example, some machines can fold the napkins into a simple square fold, while others can create more complex folds like the fan fold or the accordion fold. - Stacking

The folded napkins are then stacked neatly. Some machines have an automatic stacking system that can stack the napkins in a specific number per stack, making it convenient for packaging. - Packaging

The stacked napkins are ready for packaging. This can be done manually or with the help of an additional packaging machine. The packaged napkins are then ready for distribution.

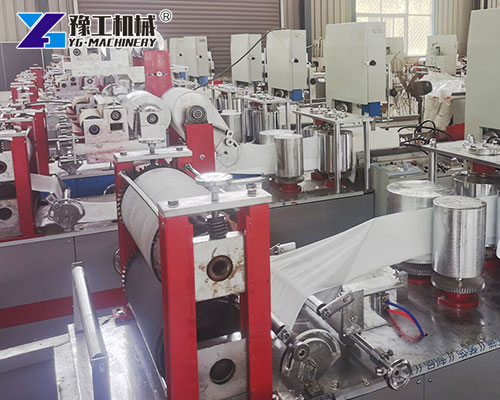

Napkin Paper Machine Line

A napkin paper machine line is a streamlined production system designed to convert raw paper rolls into finished, packaged napkins efficiently.

Core Machinery in a Napkin Paper Production Line

Raw Material Unwinder (Paper Roll Stand)

Function: Holds large rolls of raw paper (e.g., tissue paper or pulp-based sheets) and feeds them into the production line.

Feature: Equipped with tension control systems to ensure smooth, steady unwinding without creasing or tearing.

Embossing Machine (Optional)

Function: Adds decorative patterns, logos, or text to the paper surface for aesthetic appeal (common in premium napkins).

Feature: Uses heated rollers with engraved designs to emboss single or double-sided textures, enhancing product value.

Slitting & Cutting Machine

Function: Cuts the wide paper roll into narrower sheets or individual napkin sizes (e.g., 20cm x 20cm for dinner napkins).

Feature: High-precision blades or rotary cutters ensure uniform dimensions, with adjustable settings for different sizes.

Folding Machine

Function: Folds the cut paper sheets into specific shapes (e.g., square, fan, or accordion folds).

Feature: Multi-stage folding units with adjustable guides to create single-fold, C-fold, or Z-fold napkins, catering to diverse commercial needs (e.g., restaurant napkins, cocktail napkins).

Stacking Machine

Function: Collects folded napkins into neat stacks of preset quantities (e.g., 50 sheets per stack).

Feature: Automatic counting and alignment systems ensure consistent, orderly piles for easy packaging.

Packaging Machine

Function: Wraps stacked napkins in plastic film, paper bags, or boxes, often with labeling and sealing.

Types:

Manual Packaging: For small batches, using hand-operated sealers.

Automatic Packaging: High-speed machines for bulk production, integrating barcode labeling and quality checks.

Advantages of a Napkin Paper Machine Line

- High Efficiency: Fully automatic lines can produce thousands of napkins per minute, ideal for large-scale manufacturing.

- Flexibility: Adjustable settings allow quick switching between napkin sizes, folds, and embossing patterns to meet market demands.

- Cost-Effective: Reduces labor costs through automation and minimizes material waste via precise cutting and folding.

YG Machinery Services for Napkin Machines

- Installation and Training: Our professional technicians will be there to guide you through the installation process. Our training programs are customized to give operators the skills they need to operate the machines safely, make adjustments, do routine maintenance, and troubleshoot.

- Reliable Technical Support: Our dedicated team is available 24/7 to help, whether it’s remote guidance for quick fixes or on-site visits for complex issues, so you’re never down for too long.

- Genuine Spare Parts: We keep a stockpile of genuine parts, so we can quickly replace anything that breaks, keeping your production going without hiccups.

For worry-free napkin production, choose YG Machinery. Contact us today!

WhatsApp/WeChat/Phone: 86 138 3715 9132