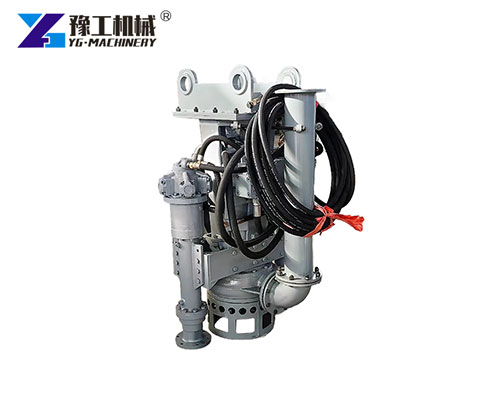

An excavator sand suction pump (also called a dredging pump attachment or submersible slurry pump) mounts on—or is suspended from—the boom of a hydraulic excavator. Driven by the carrier’s auxiliary hydraulics, it vacuums sand, silt, gravel, and slurry and discharges the mixture through a hose to a spoil area, barge, or geotube. It lets a single excavator dig, suck, and move material in one continuous operation—perfect for shallow‑water, shoreline, and pit‑clean‑out projects where conventional dredgers can’t reach.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Excavator Sand Suction Pump Parameter:

| Serial No. | Model | Flow m3/h | Lift(m) | Matching Agitator | Stirrer Torque | Excavator Tonnage |

| 1 | YG200-15 | 200 | 15 | 5.5KW | 1556 | 10T-20T |

| 2 | YG150-30 | 150 | 30 | |||

| 3 | YG300-20 | 300 | 20 | |||

| 4 | YG400-10 | 400 | 10 | 7.5KW | 1946 | 20T-30T |

| 5 | YG500-15 | 500 | 15 | |||

| 6 | YG250-35 | 250 | 35 | |||

| 7 | YG300-30 | 300 | 30 | 15KW | 2433 | 30T-40T |

| 8 | YG400-30 | 400 | 30 | |||

| 9 | YG400-40 | 400 | 40 |

Advantages of Sand Suction Pump for Excavator

- Plug‑On Versatility – Fits the same hitch used for buckets; swap in < 5 minutes.

- Alloy Wear Parts – Hi‑Cr volute and impeller extend service life 3× over cast‑iron.

- Built‑In Agitator – Side cutters fluidize compact clay so the pump never starves.

- Low Cavitation Risk – Wide vane passages maintain pressure even at 30 % slurry.

- Remote Depth Control – Excavator boom reaches 14 m deep without cofferdams.

- Minimal Footprint – No pontoons; perfect for urban canals and narrow rivers.

Field data shows users recover investment in an excavator sand suction pump within six months compared with renting a dedicated cutter‑suction dredger.

Application for Excavator Dredge Pump

The YG excavator dredge pump is a highly adaptable tool with a wide range of successful applications, including:

- River and Lake Dredging: Removing accumulated sediment to maintain water depth for navigation, flood control, and ecological balance.

- Pond and Reservoir Cleaning: Efficiently removing silt, sludge, and other debris to restore water quality and capacity.

- Construction Site Dewatering: Removing water and sediment from excavation sites, ensuring a dry and safe working environment.

- Sand and Gravel Extraction: Economically extracting sand and gravel from riverbeds, lakes, and quarries.

- Environmental Remediation: Removing contaminated sediments from waterways and industrial ponds.

- Port and Harbor Maintenance: Clearing accumulated silt and debris to maintain navigable depths for vessels.

Application Cases

| Region & Job | Result With YG Pump |

|---|---|

| Florida Marina Desilt | Removed 18,000 m³ in 12 days, marina stayed open; savings ≈ USD 170k. |

| Dutch Polder Drainage | Excavator on dike slope dredged peat slurry 200 m to geotubes, zero turbidity fines. |

| Chile Tailings Reclaim | YG‑SP150 pumped 60 % solids copper tailings back to the process plant—2,000 t/day metal recovery. |

| Qatar Beach Nourishment | Mixed sand‑water 1:1, discharged 500 m through HDPE pipe, rebuilding 1 km coastline. |

These projects highlight how an Excavator Sand Suction Pump beats barged dredges for agility and start‑up speed.

The Working Principle of an Excavator Sand Suction Pump

The YG excavator sand suction pump operates on a straightforward yet effective principle, leveraging the power of your excavator’s hydraulic system:

- Submersible Pump Head: The pump head, designed for submerged operation, is equipped with a powerful impeller and a suction inlet.

- Hydraulic Drive: The excavator’s hydraulic system powers the pump motor, driving the impeller at high speeds.

- Suction Action: As the impeller rotates, it creates a low-pressure zone at the suction inlet, drawing in water and suspended solids (sand, silt, slurry).

- Discharge: The rotating impeller then propels the mixture of water and solids through the discharge hose to the desired location.

- Agitation (Optional): Some models feature an integrated agitator or cutter head to loosen compacted sediments, enhancing the pump’s suction efficiency, particularly when dealing with densely packed materials.

Buying Guide: Five Factors To Nail Your Selection

- Carrier Capacity – Check lifting charts; the wet weight of pump + hose + slurry load must stay within 75 % of rated capacity.

- Hydraulic Flow & Pressure – YG offers gearboxes for 200–450 L/min at 250–350 bar.

- Particle Size – Choose an impeller eye and casing clearance that exceeds the target sand or gravel size by 20 %.

- Discharge Distance – Higher head models (up to 48 m) suit long pipeline runs; booster pumps optional.

- Corrosion Environment – For salt or acidic mine water, specify duplex stainless steel wetted parts.

Excavator Sand Suction Pump Manufacturer: YG Machinery

YG Machinery offers a robust and efficient excavator sand suction pump designed to transform your excavator into a powerful dredging and material transfer machine. This versatile attachment allows for the easy and cost-effective removal of sand, silt, slurry, and other sediments from various water bodies and confined spaces. Engineered for durability and high performance, our excavator sand suction pump provides a practical solution for a wide range of dredging and material handling applications, eliminating the need for dedicated dredging vessels in many situations.

WhatsApp/WeChat/Phone: 86 138 3715 9132