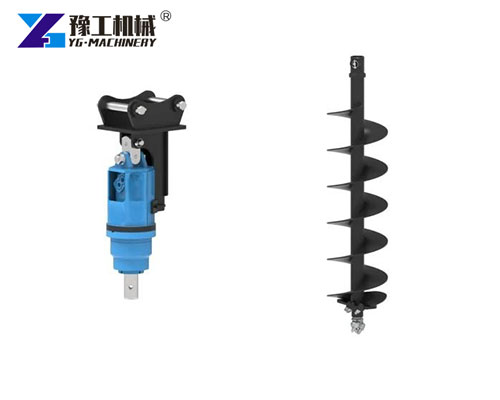

The Excavator Auger Drill is a high-torque hydraulic attachment designed to bore holes into the ground with minimal effort and maximum precision. Mounted on the boom of your excavator, it turns your carrier into a versatile drilling machine for a wide range of applications—from landscaping and agriculture to construction and foundation piling.

The system includes a drive unit powered by the excavator’s hydraulic system, a mounting bracket, and a range of auger bits for different soil conditions. YG Machinery provides multiple models compatible with 1.5-ton to 25-ton carriers, covering both light-duty and heavy-duty tasks.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Excavator Auger Drill Parameter

| Item/model | Unit | TD2000 | TD4000 | TD6000 | TD8000 | TD10000 | TD12000 | TD15000 | TD2000 |

| Torque | N.m | 2090 | 4120 | 6050 | 8100 | 11000 | 12500 | 15300 | 20800 |

| Pressure | Bar | 205 | 240 | 240 | 240 | 240 | 240 | 240 | 250 |

| Oil for range | Lpm | 30-61 | 30-68 | 38-76 | 61-121 | 61-136 | 80-140 | 80-170 | 90-180 |

| Rotary speed | Rpm | 40-82 | 32-72 | 29-58 | 37-72 | 29-64 | 22-43 | 17-34 | 16-30 |

| Hydraulic hose | Inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 1 |

| Output shaft | Mm | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

| Unit weight | Kg | 54 | 71 | 108 | 112 | 115 | 167 | 220 | 250 |

| Unit height | Mm | 750 | 750 | 750 | 850 | 980 | 980 | 980 | 980 |

| Unit max dia. | Mm | 220 | 220 | 220 | 280 | 300 | 300 | 350 | 350 |

| Auger length | m | 1-2 | 1-3 | 1-5 | 1-6 | 1-9 | 1-10 | 1-14 | 1-20 |

| Auger dia.Range | Mm | 100-500 | 100-750 | 150-600 | 150-900 | 150-900 | 150-900 | 150-1200 | 150-1200 |

| Carrier | Ton | 1.5-3 | 2.5-4.5 | 4.5-7 | 7-10 | B-13 | 13-17 | 15-20 | 17-25 |

Applications: Versatile Uses of the Excavator Auger Drill

The Excavator Auger Drill proves useful in various industries due to its adaptability and performance:

- Fence & Sign Post Installation – Drill straight and accurate holes for steel or wood posts.

- Foundation Piling – Use large-diameter augers for piling work on housing or light commercial buildings.

- Tree Planting – Perfect for planting saplings in agriculture or forestry projects.

- Utility Pole Boring – Create holes for power poles, communication towers, or lighting systems.

- Geotechnical Sampling – Enables soil testing in remote or uneven terrain.

This attachment reduces labor time, eliminates the need for manual digging, and delivers consistent hole dimensions, especially when working on sloped or tough terrain.

Key Advantages of Excavator Auger Drill

Using an Excavator Auger Drill from YG offers significant benefits:

- High Torque Output – Ensures stable drilling in rocky or dense soil without stalling.

- Precision Control – Enables accurate depth and angle adjustments via the excavator boom.

- Wide Compatibility – Fits most brands and sizes of excavators with simple mounting.

- Time Efficiency – Drills in minutes what would take hours manually or with handheld equipment.

- Low Maintenance – Fewer moving parts than conventional drill rigs, reducing downtime.

These advantages make the auger a must-have tool for contractors looking to streamline operations.

How It Works: Drilling Mechanism Explained

The Excavator Auger Drill uses a hydraulic motor driven by the excavator’s auxiliary circuit. The motor transfers torque through a planetary gearbox to the auger shaft, which spins the helical blade and bores into the soil.

Working steps include:

- Position the excavator arm vertically above the target location.

- Activate the hydraulic system to rotate the auger.

- Allow the auger to bore into the ground at a controlled speed and pressure.

- Reverse rotation to remove the auger and extracted material.

- Repeat as needed for multiple holes or deeper drilling.

This simple yet effective process makes the Excavator Auger Drill ideal for repetitive or high-volume drilling jobs.

Operating Guide for the Excavator Auger Drill

Operating the YG Excavator Auger Drill is straightforward, but following these steps will ensure safe and efficient use:

- Secure Attachment: Ensure the excavator auger drill is securely and correctly attached to the excavator’s boom according to the manufacturer’s instructions. Double-check all connections and locking mechanisms.

- Select the Appropriate Auger Bit: Choose the correct auger bit size and type based on the desired hole diameter and the type of soil being drilled.

- Position the Auger: Carefully position the auger bit over the desired drilling location using the excavator’s controls. Ensure the excavator is stable and on level ground.

- Initiate Drilling: Slowly begin the drilling process by activating the excavator’s auxiliary hydraulic system that powers the auger drilling attachment. Apply downward pressure gradually using the excavator’s boom.

- Control Drilling Speed and Pressure: Adjust the hydraulic flow and downward pressure as needed based on the soil conditions and the drilling progress. Avoid excessive force that could damage the auger or the hydraulic motor.

- Periodically Clear the Auger: As drilling progresses, periodically lift the auger slightly to allow loose soil to be removed from the hole. This prevents the auger from becoming clogged and ensures efficient drilling.

- Achieve Desired Depth: Continue drilling until the desired hole depth is reached. Monitor the depth using markings on the auger or by observing the excavator’s boom movement.

- Withdraw the Auger: Slowly and carefully lift the auger out of the hole, allowing any remaining soil to fall away.

- Repeat as Needed: Move the excavator to the next drilling location and repeat the process.

- Maintenance: After use, clean the excavator auger drill and inspect it for any damage. Regularly lubricate moving parts as recommended by YG Machinery.

Excavator Auger Attachment Manufacturer: YG Machinery

YG Machinery is a trusted global supplier of construction and demolition attachments. As a manufacturer of Excavator Auger Drills, we offer:

- Custom Fit Design – Augers tailored to your excavator model.

- Durable Materials – High-strength steel components built for tough job sites.

- Fast Lead Times – Warehouses and logistics centers in Europe, North America, and Southeast Asia.

- Full Support – Technical guidance, maintenance manuals, and live video troubleshooting.

In addition to augers, YG also produces concrete crushers, demolition shears, hydraulic breakers, and dredge pumps—offering a full range of tools to unlock your excavator’s potential.

WhatsApp/WeChat/Phone: 86 138 3715 9132