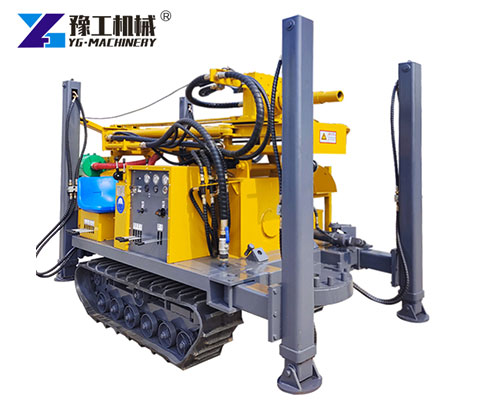

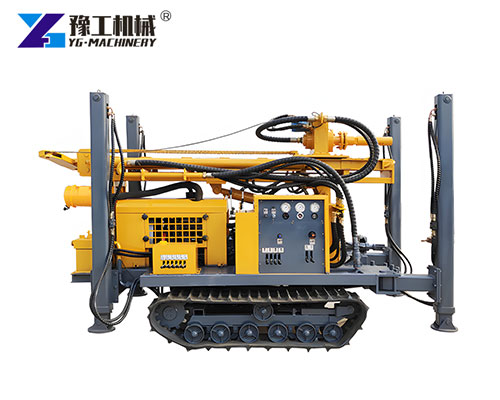

The Water Well Drilling Machine, a type of equipment designed to drill deep holes in the ground for accessing groundwater in agricultural, industrial, or residential settings. These machines can bore through soil, rock, and other layers to reach underground aquifers, allowing us to pump water to the surface.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of Water Well Drilling Machine

| Model | HY- 180 | HY- 120 |

| Drill hole depth | 80-100mm | 80m-100M |

| Maximum Opening Diameter | 80 – 200mm | 80 – 200mm |

| Drill Pipe Diameter | Φ42mm, 1.5m | Φ42mm, 1.5m |

| Motor Power | 1.5kw – 2kw | 1.5kw – 2kw |

| Pump Power | 2.2kw | 2.2kw |

| Voltage | 220V | 220V |

| Size | 700mm*700mm*2500mm | 700mm*700mm*2900mm |

| Weigh | 120kg | 150kg |

Key Features of the Water Well Drilling Machine

YG’s water well drill rigs are engineered to provide reliable operation, even in extreme conditions. They offer multiple customization options and high adaptability.

Notable features include:

- High Torque Rotary System – Ensures effective penetration into hard rock layers

- Flexible Drilling Depth Options – Models available for depths of 100m to 600 m+

- Hydraulic or Pneumatic Operation – Depending on drilling requirements

- Compact and Portable Designs – Suitable for narrow areas and difficult terrain

- Integrated Control Panel – User-friendly interface for operators

These features deliver consistent drilling efficiency while minimizing operator fatigue and operational errors.

Applications of Water Well Drilling Equipment

A water well drilling machine is widely used in multiple sectors, each requiring reliable access to underground water.

Common applications include:

- Domestic Water Supply – For homes in rural or remote areas

- Agricultural Irrigation – To support consistent crop watering

- Industrial Use – Mining sites, power plants, and factories

- Municipal Projects – Emergency or backup water sources for towns and cities

- Geothermal Projects – For geothermal heating systems

Its flexibility makes it suitable for both shallow and deep well drilling in varied geological environments.

Complete Equipment Set for Well Drilling Projects

A successful water well project involves more than just the rig. A full set of supporting equipment is required to ensure proper drilling depth, accuracy, and efficiency.

Typical equipment includes:

- Drilling Rig – The core machine for boring into the ground

- Air Compressor – Provides compressed air to flush debris and cool drill bits

- Hoist or Winch (Optional) – Lifts or lowers heavy drill tools

- Drill Bits – Various sizes and types for soft to hard rock formations

- Drill Rods – Extend the drilling depth as the borehole progresses

- DTH Hammer – Used for rock drilling with percussive force

- Adapter Joints – Connect different tools and rods securely

- Steel Wire Hose – Delivers air or water through the system

YG provides a one-stop solution for water well drilling, supplying all components as a matched system.

Working Principle: How the Drilling Process Works

The Water Well Drilling Machine works through a combination of rotation and impact mechanisms. The system drills a borehole and enables users to insert casing to protect the water supply.

Basic drilling process:

- Start Positioning – The rig is stabilized on the ground at the desired drill point.

- Drill Bit Operation – The rotating drill bit cuts into the earth’s surface.

- Drilling Rods Add Depth – Additional rods are added as drilling progresses.

- Use of compressed air – Compressed air flushes cuttings from the hole.

- Casing Placement – A steel or PVC casing is inserted to prevent hole collapse.

- Pump Installation – A submersible pump is added for water extraction.

Understanding this principle ensures better decision-making when selecting or operating the machine.

How to Pair with the Right Air Compressor

Selecting the right air compressor is critical to the performance of a water well drilling machine. The air compressor powers the down-the-hole hammer and clears debris.

Key considerations:

- Pressure Output – Ensure the compressor offers 17–25 bar for deep rock drilling

- Air Volume – A flow of 15–35 m³/min is typically required for efficient flushing

- Compressor Type – Screw-type compressors are more reliable and easier to maintain

- Fuel Type – Diesel-powered units are common in field applications due to portability

- Cooling System – Air or water-cooled systems affect operational safety in hot climates

A well-paired compressor enhances drilling speed, bit lifespan, and operational safety.

Common Questions About Water Well Drilling

- Q: How deep can a water well drilling machine drill?

A: YG rigs can typically drill between 100m to 600m, depending on the model and ground conditions. - Q: What type of ground can it handle?

A: It works on soil, sand, gravel, limestone, and hard rock formations using the appropriate bit and hammer. - Q: How long does it take to drill a well?

A: On average, 1–3 days depending on depth, terrain, and weather. - Q: How often do drill bits need replacing?

A: Bit lifespan varies by rock type but usually lasts 100–300 meters of drilling. - Q: Can the machine be transported easily?

A: Yes, especially crawler and trailer-mounted models designed for field mobility.

Water Well Drilling Equipment Manufacturer

YG Machinery is a leading manufacturer of water well drilling equipment, offering high-performance rigs and accessories built to meet international standards. With more than 20 years of experience, YG provides flexible solutions for contractors, farmers, and government water development projects.

Customers across North America, Europe, Africa, and Southeast Asia trust YG’s Water Well Drilling Machines for their durability, precision, and long service life.

WhatsApp/WeChat/Phone: 86 138 3715 9132