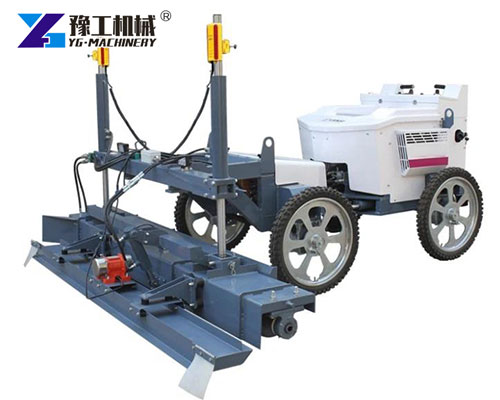

The Remote Control Concrete Laser Screed is an intelligent and compact leveling machine designed for precision and ease of use. It is operated via a wireless remote control, allowing workers to control the screeding process from a distance with enhanced safety and visibility.

This type of screed is especially useful in tight or enclosed areas where maneuvering large ride-on or boom-type machines is difficult. Despite its compact size, it delivers outstanding leveling accuracy and surface finish, making it ideal for high-spec flooring projects.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Remote Control Concrete Laser Screed Parameters

| Engine | |

| Model | HONDA GX390 Electric start |

| Type | Gasoline engine, air cooled, 4 stroke, OHV, Single cylinder |

| Power | 13hp/3600rpm |

| Lubricant L | 1.12L |

| Fuel oil volume | 6.5L |

| Fuel consumption | 313g/kWh |

| Running device | |

| Drive | Hydraulic motor and motor |

| Tyre | Antiskid tyre |

| Running speed | 0-45m/min |

| Suggest a working speed | 5m/min |

| Screed head | |

| Type | Hydraulic control, self-leveling |

| Width | 2500mm |

| Exciting force | 500N |

| Vibration frequency | 50Hz |

| Laser control system | |

| Control type | Microcomputer control |

| Size and weight | |

| Working size | 2780×2622×1980mm |

| Weight | 410kg |

Key Features of Remote Laser Screeds

- Wireless remote operation with intuitive controls

- Laser-guided leveling system for exact surface flatness

- Self-propelled hydraulic drive for smooth movement

- Vibrating and leveling integrated screed head

- Built-in sensors for slope and elevation adjustments

- Compact design for tight working conditions

Advantages of Using a Remote Control Concrete Laser Screed

- Convenient Operation

- Full-function remote control avoids manual fatigue

- Clear visibility of the screeding area during operation

- Compact Design

- Fits into narrow rooms, corridors, or basements

- Easy to transport and unload

- High Precision

- ±2–3 mm leveling accuracy with dual laser receivers

- Consistent flatness even over large floor areas

- Safer Working Conditions

- The operator stays at a distance from the wet concrete

- Lower risk of accidents or concrete defects

- Smart Control Features

- One-button start/stop

- Real-time feedback on surface level and machine status

Where Can You Use a Remote-Controlled Concrete Laser Screed?

A Remote-Controlled Concrete Laser Screed is highly versatile and can be used in a wide range of construction scenarios, including:

- Large Commercial Floors: Warehouses, malls, showrooms

- Industrial Sites: Factories, plants, logistics centers

- Public Infrastructure: Bridges, tunnels, airport terminals

- Residential Projects: Large basements, garages, driveways

- Parking Lots and Outdoor Spaces

Its portability and precise control make it suitable for both tight and open environments.

For a compact and manually operated screed, check our Walk-Behind Laser Screed solution.

How a Remote Control Concrete Laser Screed Works

Here’s how the system operates to achieve flat, level surfaces:

- Laser Transmitter Setup: A laser sets a reference height for the entire floor

- Sensor Detection: Screed head sensors receive the laser signal and adjust in real time

- Remote Control Input: The Operator uses a handheld remote to control speed, direction, and boom functions

- Screeding Action: Vibrating head levels and compacting concrete

- Real-Time Adjustments: The Operator can adapt to varying thickness and elevation changes immediately

This process delivers consistent results with minimal operator effort.

Precautions for Use of Remote Control Concrete Laser Screed Machine

- Always charge or replace the remote battery before operation

- Avoid using the machine in high-sloped areas without support

- Clean the sensors and screed plate after each job

- Use in combination with a laser transmitter for best results

- Confirm that the working area is free of obstructions and hazards

Why Choose YG Machinery?

YG Machinery leads the market in smart construction equipment, and our remote control concrete laser screeds are no exception. Each unit is tested for performance, durability, and ease of use before delivery.

- User-friendly controls and modern design

- Strict quality testing before shipping

- Expert support for setup and operation

- Exported globally to Europe, America, and Southeast Asia

Looking for a compact and powerful remote laser screed? Contact YG Machinery for expert advice and factory-direct pricing.

FAQ

What Is a Remote-Controlled Laser Screed?

A Remote-Controlled Concrete Laser Screed allows the operator to guide the machine wirelessly from a safe distance, improving visibility and safety.

Why Use a Remote Screed Instead of a Manual One?

It combines ease of use with automated control, delivering higher precision and productivity, especially in tight or enclosed areas.

Is It Safe for One-Person Operation?

Yes. The wireless remote allows full control of direction, speed, and leveling, so one operator can manage the entire process effectively.

What Are the Typical Use Cases?

- Indoor concrete floors

- Underground slabs

- Renovation work in restricted areas

What Power System Does It Use?

Most models run on diesel or gasoline engines with an electric starter and are equipped with a hydraulic drive system.

WhatsApp/WeChat/Phone: 86 138 3715 9132