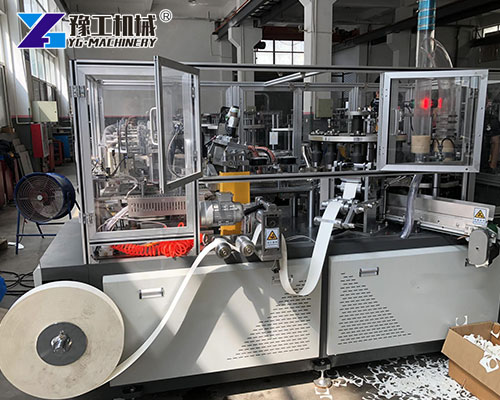

What Is a High-Speed Paper Cup Machine?

A high-speed paper cup machine is a smart machine that makes paper cups very fast. It can make more than 100 cups per minute. Some models can make up to 150–180 cups per minute. This machine is used in big factories to save time and make more cups in less time.

This machine is different from normal cup machines. It uses better parts, stronger motors, and faster systems. It is perfect for companies that need to make many paper cups every day.

WhatsApp/WeChat/Phone: 86 138 3715 9132

High-Speed Paper Cup Machine Parameters

| Model | YG- M100 | YG-M22S |

| Cup size | 2-9oz | 6oz-22oz |

| Raw material | Singe PE or Double PE coated paper | Single and double PE coating paper |

| Paper thickness | 150-260 gsm | 160-300gsm |

| Top mouth diameter | 40-76mm | 60mm-90mm |

| Bottom diameter | 28-54mm | 40mm-70mm |

| Bottom depth | 5mm-10mm | 5mm-10mm |

| Height | 30-100mm | 60mm-180mm |

| Capacity | 90-110 cups per minute | 60-90 cups per minute |

| Power | 4.5 kw | 16kw |

| Air consumption | 0.4m³/min, 0.4-0.6Mpa | 0.4m³/min, 0.5-0.8Mpa |

| Weight | 1500kg | 2200kg |

| Dimension | 1900x875x1550mm 900x600x1500mm | 1900x1350x2000mm 1220x950x2080mm |

Features of High-Speed Paper Cup Machines

This machine has many smart features:

- High Output: 120–180 cups per minute

- Low Noise: Quiet working for factory use

- Automatic Error Stop: Stops if something goes wrong

- Smart Lubrication System: Less friction and longer life

- Clean Operation: No dust or leaks during production

These features make the machine safe and easy to use.

Key Parts and Working System

The machine uses many systems that work together:

- Servo Motor Feeding System: Moves paper fast and smoothly

- PLC Touch Screen Control: Easy to see and set working data

- Cup Wall Forming System: Rolls and seals the paper wall

- Bottom Cutting and Heating System: Makes and seals the bottom

- Cup Knurling System: Makes cups leak-proof

- Stacking Table: Collects cups in neat piles

All parts are fast and strong. They help the machine run for long hours without stopping.

Who Uses High-Speed Paper Cup Machines?

This machine is great for:

- Big paper cup factories

- Food packaging plants

- OEM paper product suppliers

- Export-based cup factories

- High-demand drink brands

It helps these users save labor and increase profit by making more cups per day.

Types of Cups You Can Make

With a high-speed paper cup machine, you can make:

- Tea and Coffee Cups

- Cold Drink Cups

- Ice Cream Cups

- Soup Bowls

- Logo Printed Cups

You can use different sizes and paper types. Some machines can make cups from 4oz to 32oz.

Supported Materials

The machine can work with many kinds of paper:

- Single PE-Coated Paper

- Double PE-Coated Paper

- Printed Paper Rolls

- PLA-Coated Eco-Friendly Paper

It works best with food-grade paper that is safe and strong.

Energy-Saving and Smart Control Features

Modern high-speed machines have:

- Temperature Control Units for stable heating

- Servo Driven Systems for better speed and accuracy

- Data Monitoring Systems that show running status

- Auto Stop Functions for safety

- Power-Saving Design to reduce electric bills

These smart systems help cut costs and keep the machine safe.

What To Check Before Buying

When you choose a high-speed paper cup machine, look at:

- Speed Rating: How many cups does it make per minute

- Paper Type: What paper it support

- Cup Sizes: What sizes can it make

- Power Use: How much power does it need

- Brand of Electrical Parts: Servo, motor, sensors, PLC brand

- Warranty and After-Sales Service

A good machine should be easy to use, easy to clean, and easy to fix.

FAQ – High-Speed Paper Cup Machine

Q1: How fast is a high-speed paper cup machine?

Most models make 120 to 150 cups per minute. Some high-end types make 180 cups.

Q2: Can I make different cup sizes?

Yes. You can change the molds to make different sizes.

Q3: Is the machine safe for 24-hour use?

Yes. It is made for 24/7 operation with cooling and auto-stop features.

Q4: Does it use more power than normal machines?

No. It uses smart power-saving systems to reduce energy use.

Q5: Can it connect to other machines like packers?

Yes. It can be part of a full production line with packers and stackers.

WhatsApp/WeChat/Phone: 86 138 3715 9132