What Is A Concrete Wall Cutting Machine?

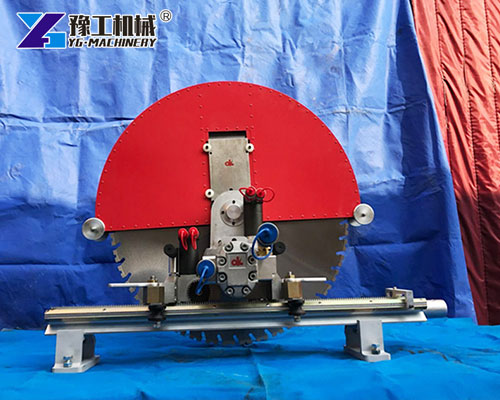

A Concrete Wall Cutting Machine is a professional tool used to cut through concrete walls, floors, and other solid structures. Also called a Hydrostress Wall Saw, it uses a high-speed rotating diamond blade mounted on a track system. The machine moves along the wall for straight, accurate cuts without causing cracks or vibrations to the rest of the structure.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Concrete Wall Cutting Machine Parameter

| Hydraulic Oil Pump | Model | YG 600 | YG 700 |

| Max. power | 25KW | 30KW | |

| Motor cooling method | Air cooling | water cooling | |

| Rated voltage | 380V 50HZ | 380V-420V 50HZ-60HZ | |

| Pressure stages | 3 | 3 | |

| Max. operating pressure | 200bar/20Mpa | 210bar/21Mpa | |

| Oil flow rate | 30-80L/min | 40-100L/min | |

| Dimensions | 600mm*650mm*1050mm | 500mm*520mm*1100mm | |

| Weight | 220kg | 140kg | |

| WallSaw | Saw blade diameter range | 800-1400mm | 800-1600mm |

| Cutting depth | 620mm | 730mm | |

| Max. working pressure | 180bar/18Mpa | 200bar/20Mpa | |

| Max. oil flow rate | 100l/min | 100l/min | |

| Gearing | Gear | Gear | |

| Rotation speed | 450/950/1300Rpm | 450/850/1200Rpm | |

| Dimension | 400mm*420mm*400mm | 400mm*420mm*400mm | |

| Weight | 38kg | 39kg |

Features Of The Wall Cutter Machine

A good wall cutter machine comes with many special features to help users work better and faster. YG’s Hydrostress Wall Saw offers:

- Strong cutting power to slice through thick concrete up to 730mm deep

- Smooth, accurate cuts with minimal dust and vibration

- Track-guided operation for stable and straight cuts

- Remote control system for operator safety

- Lightweight design for easy transport and setup

- A water cooling system to keep the blade cool and extend its life

These features save time and money on the job site and improve worker safety.

Applications Of Concrete Wall Sawing

Concrete wall sawing is important for many types of construction and renovation projects. The Wall Cutting Machine for sale is used in:

- Building construction to cut door and window spaces

- Bridge and highway projects for expansion joints

- Demolition jobs to remove parts of old concrete walls

- Large industrial sites to modify concrete structures

- Cutting stairs, beams, or thick concrete floors

No matter the size of the project, this machine delivers precise cuts with less dust and less damage to the surrounding areas.

Competitive Advantages Of Concrete Wall Cutting Machine

YG’s Concrete Wall Cutting Machine provides clear advantages over traditional cutting tools like hammers or drills:

- Clean cuts without cracking the rest of the wall

- Fast cutting speed saves time on big projects

- Less noise for a quieter job site

- Lower dust levels make the work environment safer

- Works on reinforced concrete, including steel rebar

- Reduces labor costs because one machine replaces several manual workers

Choosing YG’s Wall Saw means getting a tool that combines power, safety, and high efficiency.

How To Choose The Right Wall Saw Blade

Choosing the right wall saw blade is very important for getting the best results from your Concrete Wall Cutting Machine. Different blades work better for different types of concrete and cutting depths.

When choosing a blade, consider:

- Type of concrete (hard, medium, or soft)

- Wet or dry cutting. Wet cutting uses water to cool the blade and reduce dust.

- Quality of diamonds in the blade for longer life and faster cutting

- The thickness of the wall is used to determine the blade size

| Blade Diameter (mm) | Maximum Cutting Depth (cm) |

|---|---|

| 800 mm | 30 cm |

| 1000 mm | 40 cm |

| 1200 mm | 50 cm |

| 1400 mm | 60 cm |

| 1600 mm | 70 cm |

Pro Tip: Always use a blade slightly larger than your target depth to account for operational variances.

Using the correct wall saw blade makes cuts smoother and helps your machine work longer without problems.

Blade Lifespan In Concrete Wall Cutting Machine

The lifespan of a wall saw blade depends on:

- How hard is the concrete

- The quality of the diamonds in the blade

- Cutting speed and pressure used

- If water cooling is used during cutting

A high-quality blade can cut several hundred meters of concrete before needing replacement. To extend blade life:

- Use water cooling to prevent overheating

- Avoid forcing the machine too quickly

- Choose the right blade for the material you are cutting

- Regularly inspect the blade for damage or wear

Taking care of your blade saves money and ensures safe, clean cuts with your Concrete Wall Cutting Machine.

YG Machinery After-Sales Service For Concrete Wall Cutting Machine

When you buy a Concrete Wall Cutting Machine from YG Machinery, you receive strong support to help keep your work running smoothly. YG offers:

- Technical support for setup and operation

- Training videos to teach safe use

- Spare parts supply for fast repairs

- Remote assistance for troubleshooting

- Warranty services for peace of mind

YG Machinery has sold machines worldwide and understands different customers’ needs. We aim to help you finish your projects faster and with better quality.

FAQs About Concrete Wall Cutting Machine

Q: Can a concrete wall cutting machine cut reinforced concrete?

A: Yes, our machine cuts both concrete and steel rebars smoothly.

Q: What is the maximum cutting depth?

A: Cutting depth ranges from 200 mm to over 730 mm, depending on the model.

Q: Does the machine produce a lot of dust?

A: Water cooling reduces dust significantly, keeping the workspace safer.

Q: How can I choose the right wall saw blade?

A: Tell us your concrete type, thickness, and cutting needs. We’ll help you select the best blade.

If you’re ready to invest in a high-performance Concrete Wall Cutting Machine, YG Machinery is here to help.

Contact us now for your personalized quote on the Concrete Wall Cutting Machine!

WhatsApp/WeChat/Phone: 86 138 3715 9132