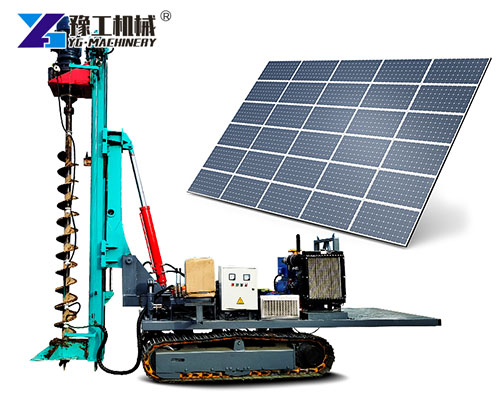

What Is A Solar Pile Driver?

A solar pile driver is a specialized type of pile ramming machine used in the construction of solar power stations. It pushes steel piles into the ground to support solar panel frames. Unlike traditional diesel drivers, it runs on solar energy. This makes it cleaner, quieter, and easier to use in off-grid or residential areas.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Solar Pile Driver Parameter

| Hydraulic photovoltaic pile driver | |||

| Overall dimensions | 4700*2100*2800mm | Drill pipe rotational speed | 180r/min |

| Track shoe width | 400mm | gradability | 30° |

| motor | 4108 | rock hardness | 6-20F |

| Drilling diameter | 80-500mm | Slide tilt angle | 120° |

| Drilling depth | 0-6m | Drill arm swing angle | left and right150° |

| Reducer torque | 13000n.m | Slide swing angle | left and right40° |

| Mainstream pump | triple pump | Driving speed | 0-3km/h |

| oil pump | 40/40/32 | ||

| Crawler photovoltaic pile driver | |||

| Overall dimensions | 4700*2200*2800mm | Hydraulic hammer flow | 50-110L/min |

| Track shoe width | 400mm | Impact frequency | 350-800BMP |

| motor | 4108 | Hydraulic system pressure | 25mpa |

| Generator power | 88kw Motor | Strong wind for heat dissipation | yes |

| Drilling depth | 0-6m | oil pump | 40/40/32 |

| Drilling diameter | 80-600mm | Driving speed | 3km/h |

Key Features Of Solar Pile Driver Machine

The solar pile driver machine has several important features:

- Solar-Powered System: Runs fully on solar panels and batteries.

- Low Noise Operation: Less than 60 dB, ideal for urban or residential work.

- Modular Design: Easy to transport and assemble.

- Automatic Controls: Helps maintain accurate and consistent pile driving.

- Sturdy Build: Works even in rocky or hard soil layers.

These features enable workers to utilize the machine in more areas with reduced fuel and maintenance costs.

Advantages Of Using A Solar Pile Driver

Using a solar pile driver gives many clear benefits:

- Zero Carbon Emissions: Helps reduce pollution on job sites.

- Lower Operating Costs: No diesel, just solar power.

- Quiet Construction: Suitable for areas with noise limits.

- Works Off-Grid: Can be used where no power or fuel supply exists.

- Meets ESG Standards: Supports green construction and LEED certification.

Pile Ramming Machine Vs. Traditional Equipment

When comparing a solar pile ramming machine to a diesel one, the advantages are easy to see:

| Parameter | Solar Pile Driver | Diesel Pile Driver |

|---|---|---|

| Carbon Emissions | Zero | High (requires fuel) |

| Noise Level | <60 dB (quiet) | >100 dB (very noisy) |

| Running Cost | Solar charging only | Diesel + maintenance |

| Work Environment | Solar sites, urban | Industrial or remote |

This demonstrates why more solar projects are now opting for solar-powered ramming machines.

Why Choose A Solar Pile Driver For Sale?

Here are three top reasons why solar pile drivers are becoming the first choice:

- Green Construction:

- Reduces on-site emissions.

- No oil spills or toxic smoke.

- Meets global environmental standards.

- Economic Operation:

- Save on fuel costs long-term.

- Lower daily maintenance needs.

- Ideal for large solar projects over months.

- Portable And Flexible:

- Compact frame for easy transport.

- Works in off-grid locations like deserts or mountain areas.

- Best for projects in Africa, Southeast Asia, and remote solar farms.

Case Study: Kenya 50MW Solar Power Plant Foundation

One of our solar pile drivers was used in a large-scale project in Kenya.

- Project Name: Ground Foundation for 50MW PV Plant

- Location: Kenya, Africa

- Challenge:

- Local rules banned diesel pile drivers.

- The soil was tough and needed deep driving.

- Solution:

- YG solar pile driver used with a 6m depth capacity.

- Solar power supports 24/7 operation.

Results:

- Piles Installed Daily: 120

- Completion Time: 2 weeks early

- Complaints/Violations: None

- Cost Saved: $6,000 in diesel + $1,500 in noise fines avoided

How To Choose The Right Solar Pile Driver Machine?

When selecting a solar pile driver machine, consider:

- Soil Hardness:

- Soft soil: a small-capacity driver is enough.

- Rocky ground: choose a machine with high torque.

- Pile Size:

- Check for compatible diameter and length.

- Daily Workload:

- For large solar farms, pick models with higher hit rates per minute.

- Mobility Needs:

- Trailer-mounted designs help on large or remote job sites.

What If It Rains Or Clouds Block The Sun?

Many buyers worry about rainy weather. But solar pile drivers come with battery systems that store energy for cloudy days.

Tips:

- Charge fully during sunny days.

- Carry spare battery packs.

- Use a backup hand-crank or diesel generator if available.

This ensures construction continues without big delays.

FAQs About Solar Pile Driver For Sale

Q1: How deep can your solar pile driver go?

A: Most models reach 4–6 meters, depending on the pile size and soil.

Q2: Is it difficult to install and use?

A: No. It has simple controls and comes with a manual. Training videos are also available.

Q3: What is the dry soil driving speed?

A: For average soil, it can install 80–120 piles per day.

Q4: How long does the battery last?

A: Full charge supports 6–8 working hours.

YG Machinery After-Sales Support

We offer strong support after your purchase:

- Free training videos and guides

- Online help in English 24/7

- Quick delivery of spare parts

- Optional setup service on-site

WhatsApp/WeChat/Phone: 86 138 3715 9132