A Slipform Curb Machine is a specialized road construction machine used for continuously casting and forming concrete curbs directly on site. Instead of using precast blocks that need to be transported and installed one by one, this machine extrudes wet concrete through a mold to form a one-piece curb.

It changes the traditional curb installation method by offering:

- Higher efficiency and speed,

- Better alignment and appearance,

- Greater structural integrity.

With advanced control and vibration systems, it produces smooth, durable curbs that meet modern construction standards.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Working Principle Of The Slipform Curb Machine

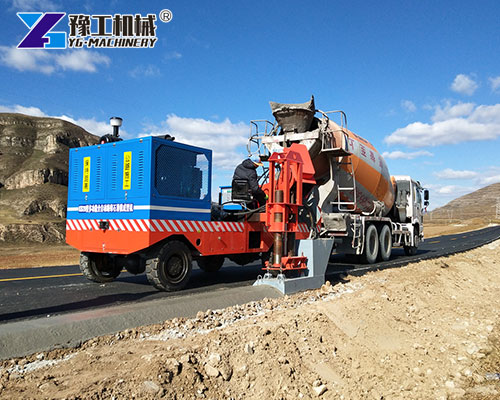

The slipform process is based on continuous extrusion and vibration compaction. At the front of the machine, a rotating screw pushes wet concrete into a forming mold, while vibration rods compact it to reach the right density. The machine then moves forward automatically, leaving a perfectly formed curb behind.

Main steps:

- Fresh concrete is fed into the hopper.

- The screw conveyor pushes material into the mold.

- Vibrators compact and densify the mix.

- The curb exits from the mold continuously.

The process ensures uniform density, precise shape, and smooth surface finish.

Main Parameters Of The Concrete Slipform Curb Machine

Typical configuration of a concrete slipform curb machine includes:

| Model | YG-20 | YG-30 | |

| Length*Width*Height | 5200*2400*2800mm | 5200*4100*2900mm | |

| Unladen mass | About 7000kg | The deadweight is greater, the crawler grip is raised, the construction stability is improved, the climbing and sliding formwork flatness, and the slope is free from interference from external factors | |

| Construction scope | Width ≤ 2000mm (road shoulder, ditch), height ≤ 600mm (kerbstone, curbstone) | Width ≤ 2000mm Height ≤ 1100mm | |

| Hopper volume | 1m³ | 0.5m³ | |

| engine | Rated power | 65kw | Inline 4-cylinder turbocharged diesel engine (for high altitude areas, increased power output) |

| Operating voltage | AC380v | ||

| Startup form | Electric start | ||

| Rated speed | 1500rpm | ||

| Heat dissipation form | Water cooling | ||

| Molding method | High-frequency vibrator (suitable for plastic concrete) | Formed shoulders and side ditches have higher strength | |

| Attached vibration motor (suitable for dry, hard concrete) | Can be paved with curbstones and higher curbstone heights | ||

| Automatic leveling system (imported DLS, optional) | Leveling range ±40mm | Imported components, temperature compensation, overvoltage, and overcurrent protection | |

| Steering form | Dual automatic steering system (imported DLS, standard) | Imported components, temperature compensation, overvoltage, and overcurrent protection | |

| Manual steering wheel (hydraulic steering gear) | |||

| Minimum turning radius | 6800mm | ||

| Paving and transfer speed | 1m-10m/min | Frequency conversion speed regulation can achieve a wide range of stepless adjustment of paving and transfer speed | |

| Travel drive form | Full-time four-wheel drive | When the road slope is ≤5%, a fully loaded 15m3 tank truck can be used for construction, and the slipform machine connection construction can be realized. | |

| Screw feeder drive type | High torque hydraulic gerotor motor | Ensure the continuous feeding of concrete, the screw feeder will not be stuck by large stones, and the concrete will be mixed twice to improve the workability of the concrete. | |

Different models are available for various project needs and concrete profiles.

Key Advantages Of The Concrete Curb Forming Machine

The concrete curb forming machine offers numerous advantages over traditional curb construction:

- Continuous Casting: Forms curbs seamlessly without joints.

- High Efficiency: Several meters per minute; reduces project time.

- Perfect Alignment: Uses laser or wire guidance for precision.

- Enhanced Strength: One-piece curb resists cracking or displacement.

- Low Cost: Reduces labor, transport, and installation expenses.

- Smooth Finish: Ensures consistent surface quality and shape.

These features make it ideal for large infrastructure and municipal projects.

Curb And Gutter Machine Applications

A curb and gutter machine can produce combined curb and gutter shapes in one operation, improving drainage and aesthetics.

It is widely used in:

- Highways and city roads for roadside curbs.

- Central medians and traffic dividers.

- Drainage ditches and edge channels.

- Landscape borders and parking lots.

With optional molds, it can form straight, curved, or custom profiles to meet different project designs.

Common Questions About Slipform Curb Machines

- What curb sizes can be made?

Each curb size requires a separate mold. Width and height can be customized. - How many molds do I need?

One mold for each curb profile. If you have several designs, you will need multiple molds. - Can the machine form curved curbs?

Yes, by using flexible guide wires, the machine can produce both straight and smooth curved lines. - How many workers are needed?

Usually 2–3 people: one to operate the machine, one to supply concrete, and one to guide alignment.

YG’s Slipform Curb Machine offers a proven solution for modern road construction. It combines speed, precision, and durability with easy operation.

Whether for highways, municipal roads, or landscaping projects, this machine ensures high productivity and professional results.

If you are planning a large-scale curb project, contact YG to get a customized quote for a slipform curb machine for sale and technical support for your construction needs.

WhatsApp/WeChat/Phone: 86 138 3715 9132