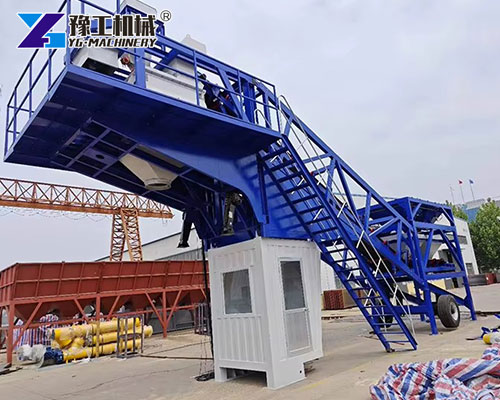

A small concrete batch plant is a compact and portable concrete mixing unit designed for small to medium-sized construction projects. It provides a convenient, efficient, and cost-effective solution for on-site concrete production. Ideal for areas with limited space, the plant integrates all essential components like the concrete mixer, aggregate storage bins, cement silo, and control systems into a streamlined design. It’s especially useful for projects that require smaller batches of concrete and frequent relocation between construction sites.

Key Features:

- Portable and compact design for easy transportation.

- Includes aggregate bins, cement silo, and control systems for seamless operation.

- Suitable for on-site mixing for residential, road repair, and landscaping projects.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Key Advantages of Using a Small Concrete Batch Plant

Using a small concrete batch plant offers several benefits that make it the preferred choice for many construction professionals.

1. Compact Design:

- Ideal for projects with limited space.

- Easy to transport, set up, and operate in tight or confined areas.

2. Mobile and Flexible:

- Can be easily moved to different job sites.

- Flexible usage for a variety of construction needs.

3. Cost-Effective:

- More affordable compared to large stationary plants.

- Reduces transportation costs since concrete is mixed on-site.

4. High Mixing Efficiency:

- Reliable and fast mixing, ideal for small batches of concrete.

- Ensures consistent quality with minimal effort.

5. Energy-Efficient:

- Designed to reduce energy consumption while maintaining high performance.

How Does a Small Concrete Batch Plant Work?

The small concrete batch plant is designed to simplify concrete production on-site.

1. Aggregate Feeding:

- Aggregates are stored in bins and automatically loaded into the mixer.

2. Cement Addition:

- Cement is stored in the silo and added to the mix as per the desired ratio.

3. Water and Additives:

- Water and additives are added to achieve the desired concrete properties.

4. Mixing Process:

- The mixer combines all ingredients into uniform, high-quality concrete.

5. Discharge:

- The finished concrete is discharged into a truck or container for easy transportation to the construction site.

Product Specifications

General Specifications:

- Production Capacity: 20–60 m³/h (depending on the model).

- Mixer Type: Choose from twin-shaft or drum mixer.

- Control System: Automated or semi-automated with touch screen control for user-friendly operation.

- Dimensions: Compact and mobile design for easy transportation.

- Power Supply: Available in electric or diesel-powered options.

- Certifications: CE certified to meet international quality and safety standards.

Applications of Small Concrete Batch Plants

The small concrete batch plant is versatile and can be used for various construction projects.

1. Residential Projects:

- Ideal for producing concrete for foundations, driveways, and landscaping.

2. Road Repair Projects:

- Perfect for small-scale road repairs that require fast, on-site concrete mixing.

3. Precast Concrete Production:

- Suitable for producing precast concrete elements in smaller quantities.

4. Urban Construction:

- Excellent for use in urban areas with limited space or areas requiring frequent relocation.

5. Agricultural Projects:

- Used for infrastructure such as barns, fences, and small bridges.

Why Choose YG’s Small Concrete Batch Plant?

When you choose YG’s small concrete batch plant, you gain access to:

1. Proven Durability:

- Built with high-quality materials to withstand harsh working environments.

2. Ease of Use:

- Simple operation and automatic control options make it easy to manage.

3. Global Service Network:

- YG offers global installation, training, and after-sales support to ensure smooth operation.

4. Customization Options:

- Choose from a range of capacities and features tailored to your specific project needs.

Small Concrete Batch Plant Customer Success Stories

1. Customer in India:

- A small mobile concrete batch plant allowed the customer to reduce production time by 30% and save on transportation costs.

2. Customer in Brazil:

- Used the plant to support infrastructure development for rural roadways, improving local access and road conditions.

Frequently Asked Questions (FAQs)

What is the ideal production capacity for a small concrete batch plant?

- The capacity typically ranges from 20 to 60 m³/h, which is perfect for small to medium-sized construction projects.

Is the plant easy to transport?

- Yes, the compact design ensures that it is easy to move and relocate between job sites.

Can the plant be used in harsh environments?

- Yes, YG’s plants are designed for durability and can operate in various harsh environments.

Contact YG for More Information & Pricing

Ready to find the best solution for your concrete needs? Request a custom quote today, and get expert advice on the perfect small concrete batch plant for your project. Of course, we also have other products available, such as mini mobile concrete batching plants.

Our team is here to help you with the best solutions, offering affordable pricing and excellent service!

WhatsApp/WeChat/Phone: 86 138 3715 9132