What Is a Paper Slitting Rewinding Machine?

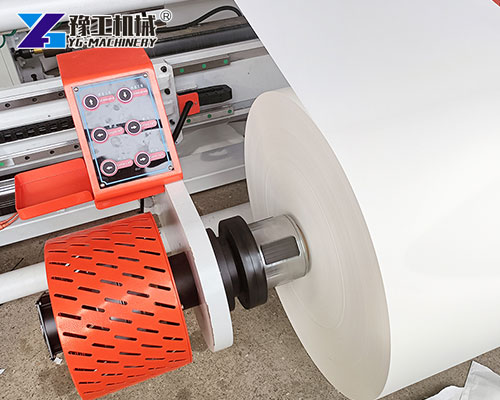

A Paper Slitting Rewinding Machine is an essential piece of equipment used in the paper manufacturing industry. It is designed to convert large rolls of paper into smaller, more manageable sizes. This machine is critical for ensuring that paper products are wound tightly, with a consistent size and shape. The process involves slitting large rolls of paper into narrower strips and then rewinding them into smaller rolls for further processing or packaging.

WhatsApp/WeChat/Phone: 86 138 3715 9132

How Does the Paper Slitting and Rewinding Machine Work?

The machine operates through a simple yet effective process:

- Slitting: The paper is fed into the machine, where it is slit into smaller widths. This is done using sharp blades or rotary knives.

- Rewinding: After the paper is slit, it is rewound onto a new core. The machine controls the tension and speed to ensure an even, tight roll.

- Automatic Control: Modern machines come equipped with automatic systems for precise tension control and speed regulation, making the process more efficient and consistent.

Paper Slitting Rewinding Machine Parameter:

| Model | YG- 1300 | YG- 1600 | YG- 1800 |

| Max width | 1300mm | 1600mm | 1800mm |

| Max Diameter for unwinding | ¢1400mm | ¢1400mm | ¢1400mm |

| Min width of slitting | 30mm | 30mm | 30mm |

| Max Diameter of rewinding | ¢1000mm | ¢1000mm | ¢1000mm |

| Speed | ≤350m/min | ≤350m/min | ≤350m/min |

| Total Power | 24kw | 26kw | 30kw |

| Power supply | 380V/50hz | 380V/50hz | 380V/50hz |

| Weight | 4000kg | 4500kg | 5500kg |

| Overall dimension(LxWxH) | 3300x3150x1930(mm) | 3300x3450x1930(mm) | 3300x3650x1930(mm) |

Why Invest in a Modern Paper Slitting Machine?

Investing in a Paper Slitting Rewinding Machine offers numerous benefits, particularly when you choose a modern, automated system. Below are some reasons to consider:

- Increased Efficiency: Faster operation speeds and automated features reduce downtime and increase throughput.

- Consistency and Precision: High-precision slitting and rewinding ensure uniform paper rolls, reducing waste and improving product quality.

- Cost Savings: Automated features reduce labor costs and improve overall productivity, providing a quick return on investment.

- Adaptability: Modern machines are designed to handle a wide range of paper types and sizes, making them versatile for various industries.

Features of the Paper Rewinding Machine

Here are some key features that set the Paper Slitting Rewinding Machine apart from traditional models:

- High-Speed Slitting: Allows for faster production cycles, increasing output and efficiency.

- Adjustable Tension Control: Ensures uniform rewinding and minimizes paper damage.

- User-Friendly Interface: Many modern machines feature digital control panels that make operation easier and more intuitive.

- Durable Construction: Built with high-quality materials for long-lasting durability, even in high-volume operations.

- Energy Efficiency: Designed to operate with minimal energy consumption, reducing operating costs.

Common Applications of Paper Slitting and Rewinding Machines

Paper Slitting and Rewinding Machines are widely used in several industries:

- Tissue Paper Manufacturing: Slitting and rewinding large rolls of tissue paper into smaller, consumer-sized rolls.

- Packaging Industry: Converting large rolls of paper into packaging materials like corrugated paper, cardboard, and paperboard.

- Printing Industry: For slitting paper rolls used in commercial printing presses.

- Sanitary Paper Products: Manufacturing products like napkins, towels, and toilet paper.

- Food Industry: Wrapping and packaging paper products for food products.

How to Choose the Right Paper Slitting Rewinding Machine Supplier?

When selecting a supplier for your paper roll slitting machine, here are a few factors to consider:

- Quality Standards: Ensure that the supplier adheres to international quality certifications, such as ISO, to guarantee the durability and efficiency of the machine.

- Customization: Choose a supplier that can offer customization in terms of size, speed, and additional features based on your specific requirements.

- After-Sales Service: A good supplier should offer technical support, machine maintenance, and spare parts availability.

- Cost: Compare prices, but remember that the cheapest option may not always provide the best value. Balance cost with features and long-term efficiency.

Other Paper Processing Equipment by YG

YG offers a wide range of paper processing machines, designed to meet various production needs. In addition to the Paper Slitting Rewinding Machine, we also provide:

- Tissue Paper Machines: For manufacturing soft, absorbent tissue paper.

- Napkin Paper Machines: Machines designed to produce napkins for the foodservice and hospitality industries.

- Flexographic Printing Machines: For high-quality, high-speed printing on paper and packaging materials.

- Egg Tray Machines: For manufacturing eco-friendly egg trays and similar products.

- Paper Cup Machines: Specialized machines for producing disposable paper cups.

- Hamburger Box Forming Machines: For creating eco-friendly, customized packaging for fast food items.

WhatsApp/WeChat/Phone: 86 138 3715 9132