A Paper Box Making Machine is used to produce food packaging boxes such as burger boxes, lunch boxes, and cake boxes. The machine shapes paperboard with folding, forming, and gluing technology. Common materials include white cardboard, coated paper, and food-grade biodegradable paperboard. With growing demand for eco-friendly packaging and the rapid takeaway industry, more manufacturers are beginning to use automated production to meet market needs.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Technical Specifications of Paper Box Making Machine

| Machine model | YG-800 |

| Paper Length | 100-450mm |

| Paper Width | 100-550mm |

| Box Angles | 10°- 40° |

| Box standard size | 50*50–320*320mm |

| Edge banding height(H) | 15-200mm |

| Occupancy of the machine | 1.2m*4m |

| Production speed | 60-160pcs/min |

| Bonding/Gluing device | Water-based adhesive |

| Paper thickness | Max 1.5mm |

| Electrical requirement | 4kw/h |

| Air requirement | 6kg/cm²*200L/min |

| Equipment size | 3.48m*1.32m*1.5m |

| Machine weight | 2T |

Types Of Paper Box Making Machines

Burger Box Forming Machine

The burger box forming machine is designed for fast-food box shapes. It runs at high speed and can produce large quantities every day. It is suitable for manufacturers supplying burger restaurants and takeaway chains.

Lunch Box Forming Machine

A lunch box making equipment model supports different box sizes. Mold changes are simple and fast. It is ideal for packaging suppliers producing meal boxes, snack boxes, and takeaway containers.

Cake Box Forming Machine

A cake box production machine is perfect for bakeries and dessert brands. It produces strong and beautiful boxes with clean folding and smooth edges. It supports custom printing and special designs.

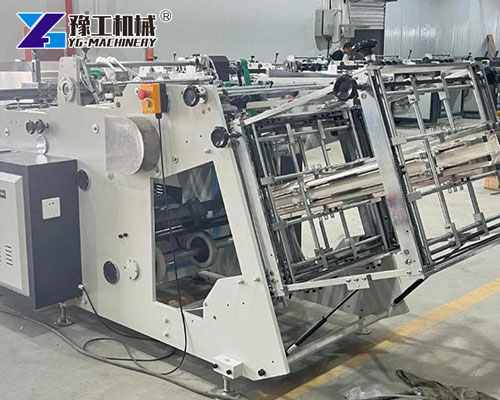

Fully Automatic Paper Box Production Line

This production line encompasses feeding, forming, folding, embossing, and gluing in a single system. It reduces labor, improves speed, and is suitable for medium to large factories.

Key Features Of Our Paper Box Making Machine

Our equipment is designed for stable and efficient production. Key features include:

- Automated forming system reduces labor costs and human mistakes

- High-speed and stable running conditions for 24/7 production

- Flexible mold replacement for different box sizes

- Touch screen and PLC smart control with an alarm system

- Support for biodegradable and eco-friendly paperboard materials

The machine also functions as a reliable food packaging box machine for various product types.

Advantages Of Using A Paper Box Making Machine

Using this type of equipment brings long-term benefits:

- Lower labor costs and improved production accuracy

- Better product consistency and food-grade hygiene level

- Ability to handle large order volumes quickly

- Eco-friendly packaging can replace plastic and foam

- Suitable for new factories and expanding operations

A Paper Box Making Machine helps improve productivity and build a stronger business.

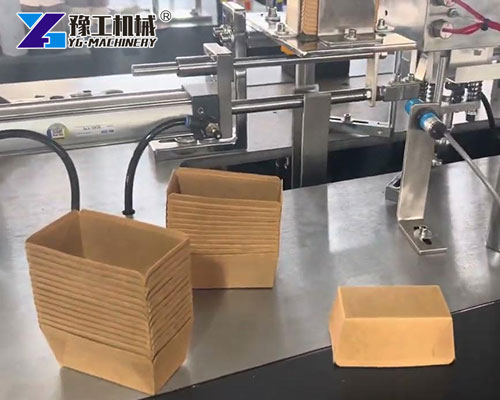

Paper Box Applications

This machine can produce many food packaging styles, including:

- Burger boxes, fries boxes, and pizza slice boxes

- Lunch takeaway boxes and fast-food boxes

- Cake boxes, macaron boxes, pastry, and dessert boxes

- Custom printed branded packaging boxes

Paper Box Making Machine Price Factors

The price depends on several main points:

- Type of automation (semi-automatic or full automatic)

- Required speed and productivity level

- Mold quantity, shape complexity, and custom request

- Installation support, spare parts, and after-sales service

Because factory needs vary, the best way to obtain final pricing is to share the box size and production target.

How To Choose The Right Food Packaging Box Machine

Choosing the correct machine requires reviewing key production needs:

- Type of box and packaging size

- Expected daily or monthly output

- Machine stability, durability, and running cost

- Supplier experience, technical support, and training service

Selecting the right equipment helps build long-term production capability.

Why Choose Our Paper Box Forming Equipment

Many manufacturers choose our machines because:

- Global certifications, including CE and ISO

- ODM and OEM customization support

- Machines are exported to global food brands and factories

- On-site installation, operator training, and spare parts supply

Our Paper Box Making Machine provides reliable performance and strong value for food packaging businesses.

Frequently Asked Questions

Q1: What materials can the machine process?

It supports white cardboard, coated paper, and eco-friendly food-grade paperboard.

Q2: How long is the mold change time?

Usually 20–60 minutes, depending on box type.

Q3: How many workers are needed to operate the machine?

Most models only require 1–2 operators.

Q4: Can the machine be customized?

Yes, including mold size, logo embossing, and automation upgrades.

Q5: Do you offer support for installation and training?

Yes, we provide online and on-site service depending on customer needs.

WhatsApp/WeChat/Phone: 86 138 3715 9132