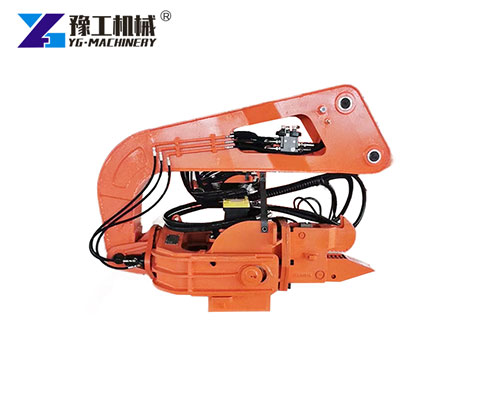

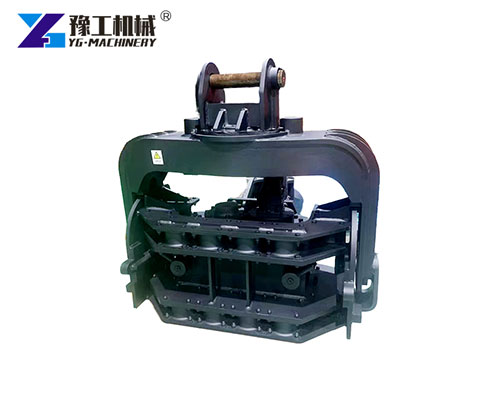

The excavator mounted vibratory pile driver is a special piling tool for excavators. The excavator vibratory hammer can replace different jaws for piling construction according to different types of piles. It combines the mobility of an excavator with the pile-driving function of a vibratory hammer, making it an ideal choice for a wide range of construction projects.

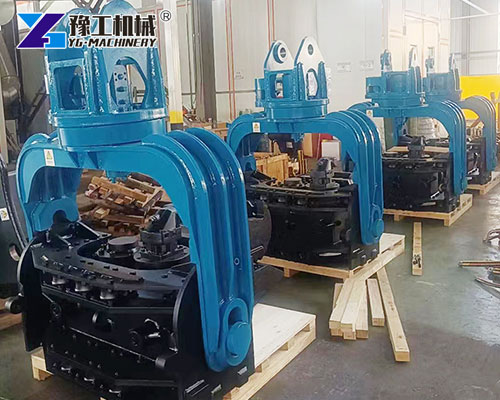

In addition, YG also provides a variety of excavator attachments. If you would like to order one, please contact us for more details and a free quote.

WhatsApp/WeChat/Phone +86 138 3715 9132

Excavator Vibratory Pile Driver Parameter

| Model | YG150D | YG250D | YG350D | YG400D | YG450D |

| Eccentric moment(kg*m) | 3.2 | 5.1/5.7 | 7.1 | 9.2 | 11 |

| Speed(rpm) | 2600 | 2600 | 2600 | 2600 | 2600 |

| Excitation force(t) | 24 | 38/42 | 52 | 68 | 81 |

| Operating pressure of oil system(bar) | 200 | 300 | 320 | 330 | 330 |

| Flow demand for hydraulic oil system(lpm) | 100 | 163 | 220 | 260 | 300 |

| Weight(t) | 1.2 | 1.6 | 2.4 | 2.5 | 2.6 |

| Excavator(t) | 8-12 | 20-25 | 25-35 | 35-45 | 40-55 |

Application of Excavator-Mounted Vibratory Hammers

The Hydraulic excavator vibratory pile driver has a diverse range of application scenarios.

In civil engineering, it is commonly used for building foundations, especially in urban construction where space is limited. It can drive piles into the ground quickly and accurately, ensuring the stability of buildings.

In bridge construction, it plays a crucial role in installing bridge piers. The high-frequency vibration of the pile driver can effectively penetrate different types of soil layers, making it suitable for various geological conditions.

In port and marine engineering, it can be used to drive piles for docks, breakwaters, and other coastal structures, with its ability to work in both shallow and relatively deep waters.

Working Principle of Vibratory Pile Driver

The working principle of the Excavator Mounted Vibratory Pile Driver is based on the generation of high-frequency vibrations.

Clamping: Secure the pile driver to the pile via hydraulic pressure for stability.

Vibration Activation: Engage the motor to generate high-frequency vibrations, loosening soil around the pile to reduce friction.

Pile Driving: The excavator applies downward force while vibrations assist in pushing the pile into the ground efficiently.

Depth Achievement: Stop vibrations once the pile reaches the desired depth to fix it in place.

Optional Extraction: Reverse the process to remove piles when necessary, adapting to soil conditions via adjustable hydraulic pressure/flow.

Advantages of Vibratory Pile Driver for Excavator

The vibratory pile driver for the excavator offers several significant advantages.

Highly efficient

Compared with traditional pile-driving methods, it can drive piles much faster, reducing the overall construction time. For example, in a large-scale construction project, using this pile driver can shorten the pile-driving process from weeks to days.

Cost-effective

Since it can be attached to an existing excavator, there is no need to purchase a separate pile-driving machine. This not only saves the initial investment cost but also reduces the maintenance and storage costs. Moreover, its fuel consumption is relatively low, which further reduces the operating cost.

Low noise and vibration pollution

The high-frequency vibrations are mainly concentrated on the pile, minimizing the impact on the surrounding environment. This makes it suitable for use in urban areas or areas with strict environmental requirements.

Features of Excavator Vibro Hammer

- High-Efficiency Hydraulic System: Imported motor doubles efficiency; adjustable frequency/amplitude adapts to soft clay, sand, or hard rock via precise hydraulic control.

- Customizable Clamping: Diverse clamps with high-strength steel/wear-resistant jaws; compact design fits confined urban sites.

- Wide Application: Handles steel sheet piles, cement piles, H steel, etc.; quick switch between driving/extraction prevents pile damage.

- Safe Operation: Low noise/vibration; safety valves maintain clamping force during sudden presses; overload/vibration monitoring ensures safety.

- Durable Design: High-strength steel structure; user-friendly excavator controls for streamlined operation in harsh environments.

Why Choose YG Excavator Mounted Vibratory Pile Driver?

YG Excavator Mounted Vibratory Pile Driver with advanced features, wide-ranging applications, and reliable service, delivering reliability, cost-effectiveness, and peace of mind. In addition, we also have other excavator attachments. If your project requires an excavator and pile driver, don’t miss the high-quality equipment from the YG brand. WhatsApp/WeChat/Phone +86 138 3715 9132