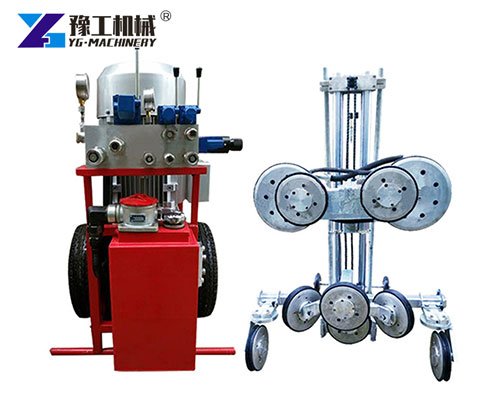

An Australian mining customer ordered a Hydraulic Wire Saw for Sale from YG Machinery for rock cutting, tested it immediately after delivery, and was very satisfied with the cutting result and stability.

Australian Project Background And Google-Based Purchasing Process

The Australian customer operates a small-to-medium mining site focused on hard rock extraction. During daily production, the team needed a precise cutting solution for separating large rock blocks without causing cracks or safety risks. Traditional blasting was not suitable for this task.

The customer started the purchasing process by searching on Google for rock cutting solutions. Keywords such as “hydraulic wire saw for mining” and “wire saw cutting hard rock” led them to several suppliers from different countries. During this stage, the buyer paid close attention to product photos, technical explanations, and real application cases.

After reviewing multiple options, the customer contacted YG Machinery to ask for more details about available cutting systems, delivery time, and whether the equipment was suitable for mining conditions in Australia.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Why The Customer Chose A Hydraulic Wire Saw Machine

Hydraulic Wire Saw Machine Selection Logic

The most important reason the customer chose a hydraulic wire saw machine was power adaptability. Mining sites often have unstable or limited electricity supply. A hydraulic system can work directly with existing hydraulic power units or diesel-driven systems.

Compared with electric systems, hydraulic solutions offer:

- Better stability in harsh environments

- Less dependence on a fixed power supply

- Strong cutting force for hard rock

The customer clearly stated that reliability mattered more than low initial cost.

Comparison With Electric Wall Saw

Electric Wall Saw Limitations In Mining Sites

Before making the final decision, the customer also considered an Electric Wall Saw. However, after the technical discussion, several limitations became clear:

- Electric systems require a stable voltage

- Long power cables are not safe in mining areas

- Motor overheating risk during long cutting hours

In contrast, the Hydraulic Wire Saw for Sale provided by YG Machinery was more suitable for outdoor mining use, especially for continuous rock cutting tasks.

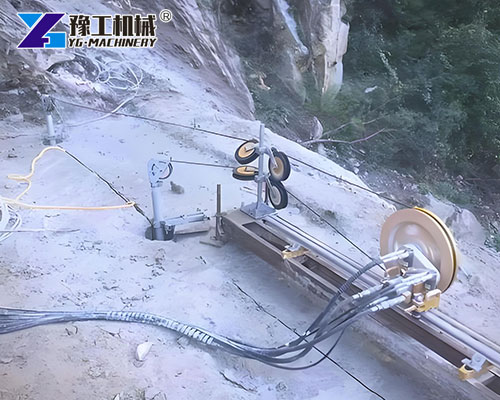

Diamond Wire Saw Configuration And Cutting Results

Diamond Wire Saw Matching With Rock Hardness

The diamond wire saw used in this project was selected based on the hardness of the mined rock. The wire beads were designed to maintain cutting efficiency while reducing wear.

During testing, the customer noticed:

- Even wear along the wire

- No sudden wire breakage

- Good cutting accuracy

This helped reduce downtime and replacement costs.

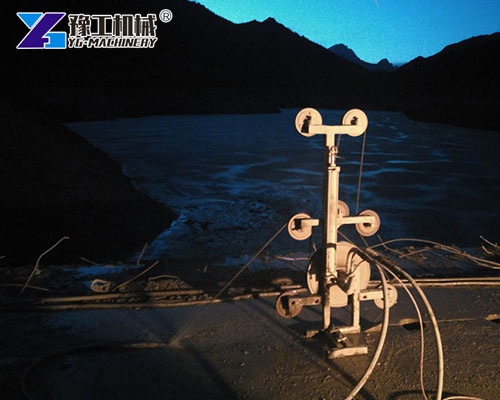

Delivery Process From Factory To Australia

The delivery process was planned carefully to ensure safe transportation. The Hydraulic Wire Saw for Sale was packed with reinforced protection for hydraulic components and cutting accessories.

The delivery steps included:

- Pre-shipment inspection and testing

- Secure packaging for long-distance sea transport

- Clear labeling for fast on-site installation

After arrival in Australia, the equipment was unpacked and assembled following the provided guidance.

Customer’s Real Feedback After On-Site Testing

Once the machine was installed, the customer carried out test cutting on real mining rock. The feedback was practical and direct.

The customer reported:

- The machine was easy to set up

- Cutting force was strong and stable

- The hydraulic system worked smoothly

- Overall performance met expectations

This positive response confirmed that the Hydraulic Wire Saw for Sale was suitable for their mining operation.

What This Case Means For Other Buyers

This Australian mining case provides a useful reference for other buyers considering a hydraulic wire saw:

- Hydraulic systems are better for sites with limited electricity

- Real working conditions matter more than paper specifications

- Wire selection is as important as machine power

For mining companies or contractors, understanding these factors helps avoid wrong equipment choices and improves project efficiency.

WhatsApp/WeChat/Phone: 86 138 3715 9132