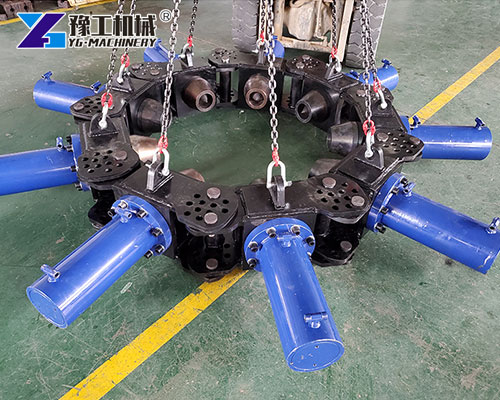

The concrete pile breaker(concrete pile cutter). This tool replaces blasting/crushing with a pollution-free, safe operation. Using a hydraulic system, it drives cylinders to generate high pressure, efficiently breaking pile heads. Features easy operation, fast speed, and suits various piles in projects like foundation reconstruction, demolition, and bridge work. WhatsApp/WeChat/Phone +86 138 3715 9132

Concrete Pile Breaker Parameter

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max. Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pin Φ35 | |||||||

| Max. Cylinder Trip | 300mm | Chisel diameter | 110mm | Single module weight | 335KG | ||||||||

| Max. Cylinder Pressure | 300MPa | Max. Hoist Capacity | ≤500mm | Single module size | 1015*865*340mm | ||||||||

Working Process of a Hydraulic Concrete Pile Breaker

The machine is attached to an excavator or other suitable carriers.

It is positioned over the concrete pile that needs to be broken.

The Hydraulic Concrete Pile Breaker uses hydraulic power to generate a strong force.

This force is applied to the concrete pile, causing it to break into smaller pieces. These pieces can then be easily removed from the construction site.

Features of the Hydraulic Pile Breaker

high-strength structure

The materials used in its construction are carefully selected to withstand the high-pressure environment during the pile-breaking process. This ensures the durability and long service life of the machine.

flexible design

Operators can adjust the breaker to different pile diameters and shapes, making it suitable for a wide range of construction projects.

operates quietly

In urban construction areas, those involved in construction need to minimize noise pollution, making this especially important.

Advantages of the Excavator Pile Breaker

High efficiency

Compared with traditional manual or mechanical pile-breaking methods, the excavator-mounted pile breaker can complete the pile-breaking task in a much shorter time. This saves a significant amount of labor and time costs.

Safety

The operator can control the breaker from a safe distance using the excavator’s control system, reducing the risk of accidents.

Flexibility

The Excavator Pile Breaker can work in various terrains and environments, providing greater flexibility for construction projects.

Concrete Pile Breaker Machine Using Guide

1. Installation

Ensure the Concrete Pile Breaker is properly mounted on the excavator or carrier. Check all connections and hydraulic hoses to confirm they are secure and leak-free before operation.

2. Adjustment

Adapt the breaker to the concrete pile’s diameter and strength. This may involve switching out jaws or modifying hydraulic pressure settings to optimize performance for the specific pile.

3. Operation

Initiate the breaker with slow, steady movements. Monitor the breaking process closely, adjusting speed or pressure as needed to ensure efficient and controlled demolition of the pile.

4. Cleanup

After breaking the pile, promptly remove all debris and broken pieces from the work area to prevent obstructions and maintain a safe, uncluttered environment for subsequent tasks.

Applications of the Concrete Pile Crusher Machine

Building Construction

The machine breaks the upper section of concrete piles to create flat foundation surfaces, ensuring structural stability and a solid base for building projects.

Bridge Construction

It removes excess pile portions post-driving, ensuring precise alignment and secure connections between piles and bridge structures to maintain overall design integrity.

Industrial Facilities Construction

Crucial for industrial sites like factories, it handles deep pile foundations for heavy machinery, efficiently breaking excess sections to ensure height alignment. Its durability and adaptability to soil conditions reduce downtime in phases like steel framing.

Port and Marine Engineering

Ideal for docks and breakwaters, the machine processes large-diameter piles in coastal environments. Its rust-resistant design and hydraulic jaws enable precise, controlled breaks for stable marine infrastructure.

Large-Scale Infrastructure

Used in highways, railways, and water conservancy projects, it manages complex piling networks, adapting to diverse geology. Its versatility and efficiency ensure timely, precise pile processing for safety-critical infrastructure.

Composition of the Concrete Pile Cutter Machine

Main Body

The main body serves as the core of the Concrete Pile Cutter Machine, housing the hydraulic system and breaking mechanism. It integrates all critical components to ensure seamless operation during pile demolition.

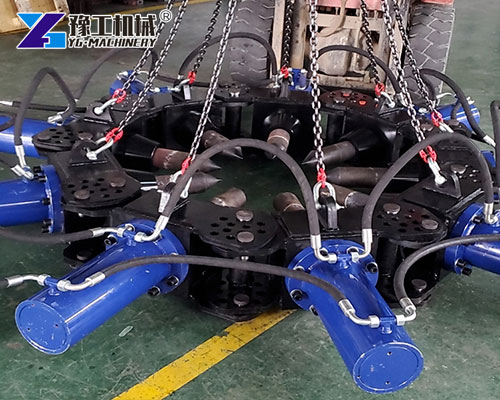

Hydraulic System

Comprising a hydraulic pump, valves, and cylinders, the hydraulic system delivers power to the breaker. It enables precise control over the breaking force, ensuring efficient and reliable performance.

Breaking Jaws

Designed to grip and break concrete piles, the jaws are crafted from high-strength alloy steel. This material ensures durability and long-term use, even under heavy-duty conditions.

Control Panels and Sensors

These components allow operators to monitor and adjust the machine’s settings in real time. Sensors provide feedback on performance, while control panels offer intuitive interfaces for safe and accurate operation.

Frame

The machine’s frame provides structural support and stability during operation. It is engineered to withstand the vibrations and forces generated during pile breaking, ensuring safe and reliable performance.

Concrete Pile Breaker Manufacturer – YG Machinery

YG is a well-known manufacturer of Concrete Pile Breakers. The company offers a variety of Concrete Pile Breakers to meet the different needs of customers. Whether it is a small-scale construction project or a large-scale infrastructure project, YG can provide the right solution. YG also provides excellent after-sales service, including technical support, spare parts supply, and maintenance services. WhatsApp/WeChat/Phone +86 138 3715 9132