The automatic paper cup machine (or paper cup making machine) is a high-efficiency device designed to produce disposable paper cups in large quantities. It automates the process of cutting, shaping, and sealing paper or coated paper into cups for hot or cold beverages. YG’s automatic paper cup machine combines advanced technology and user-friendly features to meet global demand for eco-friendly packaging solutions.

WhatsApp/WeChat/Phone +86 138 3715 9132

Automatic Paper Cup Machine Parameters

| Name | Fully automatic paper cup-making machine | |

| Model | YG-S800 | |

| Paper Cup Size | 3-16OZ | |

| Raw Material | One-sided or two-sided PE-coated paper(Single PE or Double PE-coated paper) | |

| Speed | 75-85 pcs/min | |

| Suitable paper weight | 160-300g/㎡;±20g/㎡ | |

| Voltage supply | 380V(220V) 50HZ | |

| Cup size | bottom35-70mm,top45-90mm high32-135mm | |

| Working Air Source | 0.4-0.6Mpa; 0.4m³/min | |

| General power | 6kw | |

| Net weight | 2000kg | |

| Measurement (mm) | Machine dimension | L:2100mm;W:1200mm;H:1800mm |

| Cupholder | L:900mm;W:600mm;H:1500mm | |

| Cup Side Sealing | EVERGREEN Ultrasonic | |

| Bottom Knurling | Hot air system | |

| The mold can be customized according to customer requirements | ||

Types of Paper Cup Machines

YG offers a variety of paper cup machines tailored to different production needs:

Fully Automatic Paper Cup Machine: High-speed production with minimal manual intervention.

Semi-Automatic Paper Cup Machine: Affordable option for small to medium output.

Custom Paper Cup Forming Machine: Design-specific models for unique cup shapes/sizes.

Multi-Layer Paper Cup Machine: Creates insulated cups for hot drinks like coffee.

Eco-Friendly Paper Cup Machine: Uses biodegradable materials for sustainability.

Each type adapts to diverse business requirements, from cafes to large-scale manufacturers.

Advantages of Using a Paper Cup Machine

Cost Savings: Reduces labor costs and material waste compared to manual production.

High Efficiency: Produces up to 500 cups per minute for quick order fulfillment.

Hygiene: Minimizes human contact, ensuring sanitary cup production.

Versatility: Creates cups for coffee, tea, smoothies, and even soups.

Customization: Supports logos, colors, and sizes for brand differentiation.

How to Choose the Paper Cup Production Machine

Consider these factors when selecting a paper cup production machine:

Production Capacity: Match the machine’s speed to your order volume.

Material Compatibility: Ensure it works with paper, PE-coated paper, or biodegradable materials.

Budget: Balance upfront cost with long-term maintenance expenses (e.g., automatic paper cup machine price).

After-Sales Support: Choose brands like YG with global service networks.

Energy Efficiency: Look for models with low power consumption.

Applications of Paper Cup Forming Machines

Paper cup machines are widely used in various industries:

Food & Beverage: Cafes, restaurants, and food trucks for hot/cold drinks.

Events: Weddings, festivals, and conferences for disposable serving.

Healthcare: Hospitals and clinics for single-use medicine cups.

Retail: Convenience stores for grab-and-go beverage sales.

Industrial: Construction sites and factories for worker hydration.

YG’s machines are trusted by businesses worldwide for their reliability.

5 steps to paper cup production

Material Feeding: Rolls of paper or film are loaded into the machine.

Cup Shaping: A die presses the material into cup form.

Sealing: The cup edge is sealed to prevent leaks.

Printing: Optional step to add logos or designs (requires a paper cup printing machine).

Packaging: Cups are stacked and packed using a paper cup packaging machine.

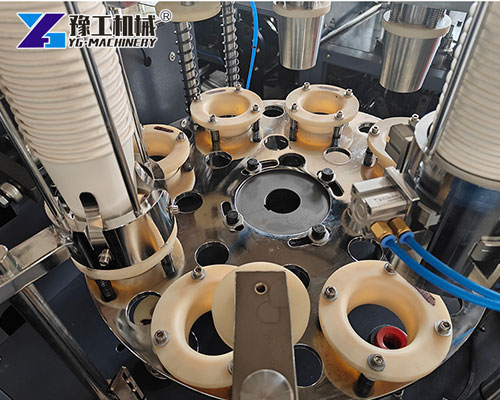

Paper Cup Machine Components

Feeding System: Delivers raw materials to the production line.

Forming Unit: Shapes the cup using heated dies.

Sealing Mechanism: Ensures leak-proof edges.

Control Panel: Manages speed, temperature, and settings.

Safety Guards: Protect operators during operation.

YG’s components are built with durable materials for long service life.

Customization Options for Paper Cup Machines

YG offers tailored solutions for custom paper cup forming machines:

Cup Design: Choose from cone, cylindrical, or custom shapes.

Size Range: Produce cups from 2 oz to 20 oz.

Printing Features: Integrate full-color logos or patterns.

Material Types: Support for eco-friendly or premium coatings.

Auxiliary Equipment for Paper Cup Production

A complete setup requires these specialized machines working together:

Paper Cup Printing Machine

Prints vibrant logos and designs onto paper rolls. Handles multicolor patterns for branding coffee cups or event souvenirs.

Paper Cup Die-Cutting Machine

Cuts printed paper into precise cup shapes. Ensures consistent sizing for 8oz, 12oz, or 16oz cups.

Paper Cup Packaging Machine

Automatically stacks and wraps finished cups. Saves labor and keeps products hygienic during transport.

Cup Lid Machine

Makes leak-proof plastic or biodegradable lids. Compatible with hot/cold drink cups.

YG’s fully automatic paper cup production line links these machines seamlessly, boosting output while cutting costs. Request a customized solution today.

Why Choose YG for Paper Cup Machines?

YG offers automatic paper cup machine prices that blend affordability with premium quality, backed by 20+ years of industry expertise. Our machines undergo rigorous 72-hour stress tests to guarantee durability and precision, ensuring they outperform competitors. Trusted by 500+ global clients, we refine designs using real-world feedback for practical, reliable solutions.

Innovation meets cost-effectiveness with energy-saving technology that cuts power consumption by 25% and intuitive controls that reduce operator training time. Whether you need biodegradable cup systems or high-speed production lines, YG tailors machines to scale with your business. Don’t just invest in a machine—choose a partner that slashes long-term costs while delivering exceptional results. Request a quote today and experience the YG difference!

WhatsApp/WeChat/Phone +86 138 3715 9132