Starting a paper cup factory is a smart business choice. Paper cups are used every day in coffee shops, restaurants, offices, schools, and events. With the global push for eco-friendly packaging, the demand for disposable paper cups keeps growing.

To run a successful factory, you need more than just one machine. A complete paper cup production process needs several machines working together. Each machine has its own role, from raw paper to finished cups ready for sale.

This guide explains what machines are needed to start a paper cup factory, how they work, and why each one is important. The explanation is simple and practical, especially for new investors or first-time factory owners.

Understanding The Paper Cup Manufacturing Process

Before buying machines, it is important to understand the basic paper cup manufacturing process. This helps you avoid wrong purchases and saves money later.

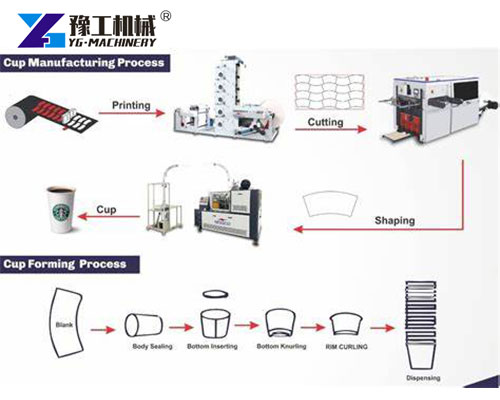

A standard paper cup production process includes:

- Preparing paper material

- Printing and cutting paper

- Forming paper cups

- Counting and packing finished cups

Each step needs the right machine. Skipping one step or using the wrong equipment can reduce quality and slow production.

Paper Cup Raw Material Cutting Machine

The first machine needed is the Paper Cup Raw Material Cutting Machine. Paper cups are made from large paper rolls. This machine cuts the paper roll into sheets of the right size.

Main functions include:

- Cutting paper rolls into flat sheets

- Keeping size accuracy

- Reducing paper waste

This machine is important because clean and accurate cutting makes later steps easier. It also helps control raw material costs, which is very important for a paper cup factory setup.

Paper Cup Flexo Printing Machine

If you plan to sell branded cups, a Paper Cup Flexo Printing Machine is needed. This machine prints logos, designs, and text on the paper.

Key advantages:

- Uses food-grade, water-based ink

- Supports multi-color printing

- Works well for high-volume production

Printed cups are more popular in coffee shops and chain stores. Adding printing to your paper cup production line increases product value and profit margin.

Paper Cup Die Cutting Machine (Fan And Bottom Cutting)

The Paper Cup Die Cutting Machine is one of the most important machines in the paper cup manufacturing process. It is used to cut fan-shaped paper pieces for the cup wall and round paper pieces for the cup bottom.

This machine works after printing and before cup forming. Its cutting accuracy directly affects the shape, strength, and sealing quality of the final paper cup.

Main functions include:

- Cutting printed paper into accurate fan shapes

- Cutting round paper pieces for cup bottoms

- Making clean and smooth cutting edges

Key advantages:

- Supports different cup sizes and molds

- Easy mold change for flexible production

- Stable and fast operation for continuous work

If the cutting accuracy is poor, the cup wall may not fit well with the cup bottom. This can cause weak sealing or leakage. That is why a stable Paper Cup Die Cutting Machine plays a critical role in ensuring consistent quality in a paper cup factory.

Paper Cup Making Machine

The core equipment is the Paper Cup Making Machine. This machine forms paper cups by heating, folding, and sealing the paper parts together.

Main features:

- Automatic cup forming

- Stable speed and output

- Suitable for hot and cold cups

This machine connects all previous steps. Without a reliable paper cup-making machine, the whole paper cup production line cannot work smoothly.

Paper Cup Stacking Machine

After cups are formed, they need to be stacked neatly. A Paper Cup Stacking Machine does this automatically.

Why it matters:

- Keeps cups clean and aligned

- Matches high-speed cup machines

- Prepares cups for packing

This machine reduces manual work and helps keep production organized.

Paper Cup Counting And Packing Machine

A Paper Cup Counting And Packing Machine is used to count cups and pack them into plastic bags or bundles.

Main advantages include:

- Accurate automatic counting

- Adjustable packing quantity

- Reduced labor cost

For factories that want stable quality and fast delivery, this machine is a key part of the paper cup factory setup.

Paper Cup Shrink Wrapping Machine

Some factories also use a Paper Cup Shrink Wrapping Machine. This machine wraps cups with shrink film for better protection.

Benefits:

- Protects cups during transport

- Makes packaging clean and professional

- Suitable for export orders

This step improves product appearance and reduces damage during shipping.

Carton Packing Machine For Paper Cups

For large-scale production, a Carton Packing Machine for Paper Cups is very useful. It packs finished cups into cartons automatically.

Key functions:

- Automatic carton loading

- High packing efficiency

- Ready for warehouse or export

This machine completes the paper cup manufacturing process and helps factories move toward full automation.

How To Choose Machines For Your Paper Cup Factory

When planning what machines are needed to start a paper cup factory, do not buy blindly. Consider your real needs.

Important points to think about:

- Daily production target

- Cup sizes and types

- Labor cost in your country

- Power supply and factory space

A well-matched paper cup production line runs faster, wastes less material, and makes better-quality cups.

Final Thoughts On Paper Cup Factory Setup

Starting a paper cup factory is not complicated if you understand the full process. From cutting paper to packing finished cups, each machine plays a clear role.

A complete paper cup manufacturing process includes:

- Raw material preparation

- Printing and cutting

- Cup forming

- Counting and packing

Choosing the right machines from the start helps reduce risks and improve long-term profits. With proper planning, a paper cup factory can become a stable and growing business.