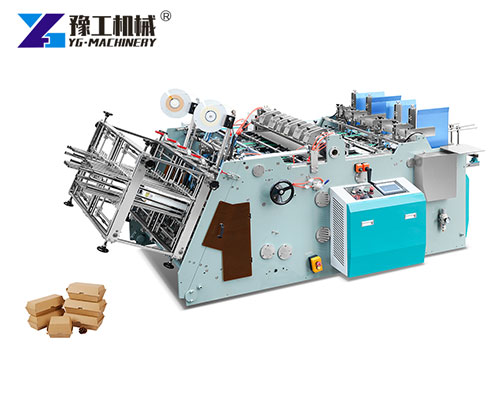

The Burger Box Making Machine is a specialized piece of equipment designed to produce cardboard or paper-based containers used for packaging hamburgers and other food items. This machine automates the folding, gluing, and forming processes, ensuring consistent quality and size for each box. It is widely used in fast food chains, packaging factories, and eco-friendly container production lines.

With growing demand for sustainable and hygienic food packaging, the Burger Box Making Machine provides an efficient solution that meets both volume and quality expectations.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of the Burger Box Making Machine

| Machine model | YG-800 |

| Paper Length | 100-450mm |

| Paper Width | 100-550mm |

| Box Angles | 10°- 40° |

| Box standard size | 50*50–320*320mm |

| Edge banding height(H) | 15-200mm |

| Occupancy of the machine | 1.2m*4m |

| Production speed | 60-160pcs/min |

| Bonding/Gluing device | Water-based adhesive |

| Paper thickness | Max 1.5mm |

| Electrical requirement | 4kw/h |

| Air requirement | 6kg/cm²*200L/min |

| Equipment size | 3.48m*1.32m*1.5m |

| Machine weight | 2T |

Key Features of Hamburger Box Making Machine

YG’s machine stands out for its precision, speed, and low maintenance requirements. Whether you’re producing boxes for fast-food chains or takeaway outlets, the machine delivers consistent results.

- High-Speed Production: Capable of producing up to 3000 boxes per hour, depending on the model.

- Eco-Friendly Compatibility: Supports recycled paperboard and biodegradable materials.

- Adjustable Molds: Easily change box sizes and shapes to match product demands.

- Automatic Feeding System: Ensures continuous operation with minimal downtime.

- Compact Design: Saves space while maintaining industrial-grade output.

These advantages make the Hamburger Box Making Machine an ideal choice for businesses aiming to reduce labor costs and improve packaging efficiency.

Real-World Use Cases of the Burger Box Making Machine

The YG Burger Box Making Machine has been successfully deployed in various commercial environments across North America and Europe. Here are a few examples of its application:

- Food Packaging Plants: Large manufacturers use it for the mass production of custom-branded burger boxes.

- Fast-Food Franchise Suppliers: Ensures box standardization across multiple restaurant locations.

- Eco-Packaging Startups: Leverages the machine to produce biodegradable containers for gourmet burgers and organic fast food.

- Event Catering Businesses: Meets short-term, high-volume packaging needs for festivals and fairs.

- Delivery-Based Kitchens: Produces custom-fit boxes that enhance food presentation and heat retention.

These cases show the machine’s flexibility across small and large operations.

How the Hamburger Box Making Machine Works

The working principle of a hamburger box-making machine is based on automatic paper feeding, heating, shaping, and forming. Once the paperboard is loaded, the machine completes the following steps:

- Feeding: Pre-cut paper sheets are fed automatically into the mold station.

- Heating & Folding: The machine heats the paper for flexibility and folds it into shape.

- Gluing: Hot-melt glue or cold glue is applied at specific joints to form a secure box.

- Shaping & Ejection: The shaped box is pressed into its final form and ejected into a collection tray.

This smooth and fast process ensures that each burger box is perfectly formed and ready for use.

Why Choose YG Burger Box Forming Machine

Choosing the right Burger Box Forming Machine is crucial for packaging efficiency and YG stands out due to its robust engineering with heavy – duty steel frames and long – life components, energy – efficient design minimizing power consumption while keeping output speed, easy operation with simple control panels and touch screen interfaces needing minimal training, versatile output for boxes of burgers, chicken, sandwiches and combo meals, and global support including overseas installation, training and after – sales service, making it a trusted partner for long – term performance and reliability in the food packaging industry.

WhatsApp/WeChat/Phone: 86 138 3715 9132