A client in Indonesia ordered a Concrete Wire Saw for Sale set from YG Machinery. The customer paid the full balance, the goods were shipped, and the equipment is now in site testing.

Customer Demand In Indonesia

An Indonesian demolition company works on heavy reinforced concrete structures. Their main needs were:

- Faster cutting to shorten project time.

- Lower labor and machine handling costs.

- High cutting accuracy to protect nearby structures.

They compared suppliers and focused on cutting efficiency, system stability, and quick after-sales support. YG’s proven cases and spare parts plan helped secure the order.

WhatsApp/WeChat/Phone: 86 138 3715 9132

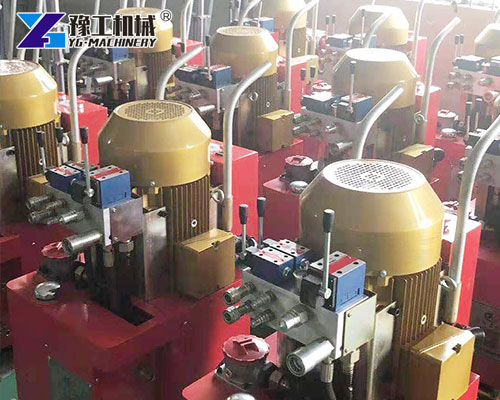

Product Parameters of Diamond Wire Saw Machine

YG recommended a robust diamond wire saw machine matched to the client’s work. Typical parameters we supplied:

| Wire Saw Wheel | Parameters | Hydraulic Pump Station | Parameters |

| Wire Drive Mode | hydraulic | Rated Output Power | 22/25KW |

| Model Type | HM-40/80 | Working Voltage | 380v 50Hz |

| Minimum Input Power | 25HP/33HP | Hydraulic Pump Station | Gear pump |

| Output Shaft Speed | 350/940/1300r/min | Motor Working Flow | 40-100L/min |

| Maximum Wire Length | 18m | Working Pressure | 15-20Mpa |

| Feeding Method | Fully hydraulic | Oil Tank Volume | 16L |

| Wire Saw Wheel | 64kg | Weight | 98kg |

| Motor Weight | 13kg | Dimension(mm) | 650*550*1150 |

| Cutting Type | Transverse and longitudinal cutting |

These specs let the machine cut large, reinforced concrete blocks and beams with steady speed and control.

Hydraulic Wire Saw For Concrete Advantages

The hydraulic wire saw we delivered fits large demolition tasks. Matching choices and benefits:

- Powerful motor and hydraulic feed give steady wire tension.

- Diamond wire cuts both concrete and embedded rebar cleanly.

- Multi-angle cutting setup allows straight or curved cuts.

- Operation is simple: clamp track, set wire path, start cutting.

Advantages on the job: precise cuts, low vibration, low noise, and long diamond wire life. YG supplied a hydraulic power station and extra diamond wire for fast replacement.

Wire Saw Cutting Machine Transport

The complete wire saw cutting machine kit was packed and shipped by sea to Jakarta port. Delivery and start-up steps:

- Factory test run and full documentation.

- Wooden crates and anti-rust treatment for parts.

- Sea freight to Jakarta and customs clearance support.

- Remote video guidance from YG engineers for setup.

The customer completed commissioning within three days and began cutting on schedule.

Customer Feedback From Indonesia

After initial use, the customer reported strong results:

- Cutting efficiency rose by 40% compared to older methods.

- Diamond wire life was long; maintenance cost dropped.

- The machine ran stably for continuous shifts with no major faults.

- Accuracy met their strict demolition tolerances.

The client is satisfied and plans to buy more cutting sets for other projects.

YG After-Sales Service And Support

YG guarantees full support for every Concrete Wire Saw for Sale delivered:

- Spare parts and extra diamond wire are always available.

- Remote operation training and on-site visits when needed.

- Customization for track length, power unit, and wire types.

- Fast response to technical queries to avoid work stops.

This strong service record builds confidence for large demolition firms.

YG offers full concrete cutting solutions and global delivery. If you need a Concrete Wire Saw for Sale or accessories like the hydraulic power pack and spare wire, contact YG Machinery. We provide quotes, technical sheets, and timelines for bulk orders and long-term projects.

WhatsApp/WeChat/Phone: 86 138 3715 9132