A construction company in Malaysia ordered a Hydraulic Wall Saw for Sale from YG Machinery. The shipment was delivered, installed, and used for several weeks. The team reported strong performance and smooth operation.

Hydraulic Wall Saw: Project Background In Malaysia

The client is a civil contractor in Greater Kuala Lumpur. They handle building renovation, bridge strengthening, and structural openings for MEP pipelines. On this project, they needed to open doorways in 300–600 mm reinforced concrete walls and trim beams near active offices.

Key challenges on site:

- Limited work windows due to noise rules.

- Rebar-heavy walls needing straight cuts with tight tolerances.

- Dust and water control in an occupied building.

A hydraulic wall saw solved these issues with low vibration, high torque, and controlled cooling. The team could cut thicker sections with fewer passes and less risk to the remaining structure.

YG supplied a hydraulic wall saw that fits these needs. The hydraulic wall saw worked well in narrow sites and tall structures.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Concrete Cutting Equipment: Why The Client Chose Hydraulic

The contractor compared several concrete cutting equipment options—hand saws, wire saws, and electric wall saws. They selected a hydraulic system for four reasons:

- Higher Power Density: Hydraulic power delivers steady torque for deep cuts in RC walls.

- Lower Vibration: Compared with impact tools, it protects the surrounding structure.

- Clean, Straight Lines: Rail-guided slicing gives a true, plumb cut that is easy to finish.

- Better Duty Cycle: Hydraulic units keep performance stable during long cuts.

On past jobs, hand tools slowed down on rebar. The hydraulic setup kept blade speed and feed under control, reducing blade glazing and improving blade life. This concrete cutting equipment choice matched the site’s precision and safety goals.

Concrete Wall Cutting Machine: Main Advantages On-Site

When used as a concrete wall cutting machine, the system delivered clear gains:

- High Power & Efficiency: The hydraulic power pack kept the blade at optimal speed. Cuts stayed fast even in dense aggregate.

- Precise Thick-Wall Cutting: With a blade up to 1600 mm, the team achieved depths over 700 mm (job-dependent). Edges were straight, with minimal chipping.

- Rugged Build: Aluminum-steel carriage, rigid rails, and sealed connectors handled dust and moisture.

- Operator-Friendly Control: A wired pendant provided speed, start/stop, and emergency shutoff. Fine feed helped avoid over-cutting corners.

- Better Safety: Less kickback and rebound versus handheld tools; lower noise and vibration near occupied spaces.

These benefits made the concrete wall cutting machine ideal for structural openings, beam trimming, and section removal.

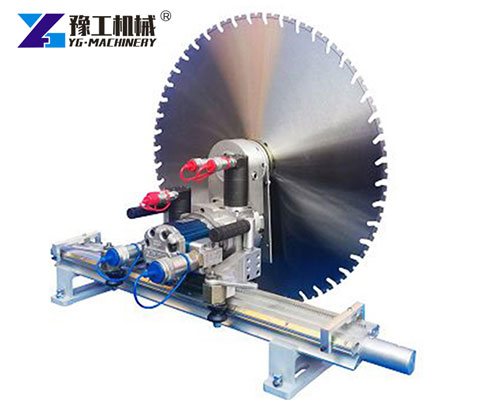

Parameters of Hydraulic Wall Saw for Sale

For this order, the contractor chose a mid-to-large kit that balances power and portability. High Frequency Wall Saw specifications:

| Saw Blade | |

| Max. cutting depth | 510mm |

| Max. saw blade | φ1200mm |

| Saw blade fixing(flush cuts) | 6 countersunk head screws,110mm graduated circle. |

| Electric motor(water cooling & high frequency) | |

| Max. Output Power | 16kw |

| IP Classification | IP 67 |

| Weight | |

| Wall Saw 105DM Incl. Feed Electric Motor | 27kg |

| Electric Main Motor 16kw | 18kg |

| Control Unit | |

| Voltage | 380-460V(single phase available) |

| Frequency | 50Hz/60Hz |

| Weight | 19kg |

| Wireless Control | 2kg |

Shipping And Delivery Process

YG handled export and local delivery simply and clearly:

- Pre-Shipment Test And QC In the Factory.

- Secure Packing With Anti-Corrosion Film And Wooden Crate.

- Sea Freight From China Port To Port Klang (or Chosen Port).

- Customs Documents: Invoice, Packing List, Certificate Of Origin.

- Local Truck Delivery And Unloading At Site.

Each step included photos and tracking updates for the customer.

Client Feedback From The Malaysia Jobsite

The customer’s summary after full rollout:

- “Cutting thick RC walls is now faster and cleaner. Edges are straight and square.”

- “Noise and vibration are lower than with impact tools, so work permits are easier to get.”

- “Setup is simple. Two people can mount rails and start cutting quickly.”

- “Less rework saves both time and money on every opening.”

They confirmed they will use the same kit on an upcoming hospital retrofit and a bridge bearing replacement project.

Need a precise, powerful solution for thick concrete? Ask for a Hydraulic Wall Saw for Sale package with rails, blades, and cooling matched to your site in Malaysia. Get a detailed quote, lead time from YG Machinery today.

WhatsApp/WeChat/Phone: 86 138 3715 9132