The French municipal water company ordered an Underwater Dredging Robot from YG Machinery and has received the unit.

Customer Needs In France

A city water authority in France faced heavy sediment in ports and reservoirs. Their problems were clear:

- Manual dredging was slow and risky.

- Ship-based dredging costs too much and disturbs water life.

- EU rules require low environmental impact and clean methods.

The client needed a new tool that was efficient, safe, and kind to the environment. They wanted fewer crew on the water and a system that could work continuously with precise control.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Matching The Right Solution — Robotic Dredging Machine

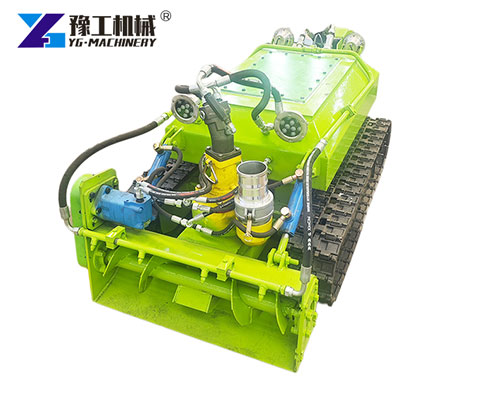

We recommended the dredging robot as the best fit. The robotic dredging machine has three core strengths:

- Automated Sediment Removal: The robot vacuums and moves silt steadily.

- Precise Positioning: GPS and sonar help the robot work in the exact spots.

- Eco-Friendly Operation: The machine minimizes water churn and keeps fine particles near the seabed.

Compared with old ways, this solution needs fewer people and much less fuel. It also lowers the risk to divers and keeps fish and plants safer. The French team liked that the system can be tuned for local water and sediment types. YG’s experience and prior cases made the choice easy.

Underwater Dredging Robot Parameter

| Robot body | Robot size: 1650mm×900mm×600mm Drainage width: 900mm Travel speed: 3-17M/min | |

| 4-inch underwater slurry pump | Used for underwater pumping of sludge Pumpable particle diameter: 40mm (can be changed according to customer needs) Lift: 25 meters (horizontal conveying distance 100-150 meters) | 1 |

| Underwater hydraulic power source | Waterproof hydraulic system | 1 |

| Robot main control cabin (underwater) | Used to control all actions of the robot, including the start and stop of underwater hydraulics and the lighting system. | 1 |

| Underwater lighting system | 2 LED lights | 1 |

| Underwater camera system | Equipped with 1 underwater camera | Optional |

| Cable winding system | Electric drive (or manual), speed 0-10 r/min | 1 |

| Underwater pipeline | 50 meters | 1 |

| Ground electric control system | ||

| Main electric control cabinet | Used to power various ground systems. | 1 |

| Main control console | Robot ground main control system, used to control the work of underwater robots | 1 |

| Attachments | Sewage pipe, 20 kg pressure resistance, steel frame, 50 meters long. | Optional |

| Work efficiency | 200 cubic meters per hour | |

Delivery And Implementation In France — Dredging Equipment For Sale

The export and setup process was smooth and clear. Steps included:

- Manufacture: The unit was assembled and fully tested in our factory.

- Export Clearance: We prepared all export documents and handled customs.

- Local Delivery: The robot was shipped to the French port and arrived on schedule.

On-site, we provided: remote support, an operation manual, and live training sessions. Engineers helped the local team test the robot in the port and run the first dredging round. The robot started work soon after arrival.

On-Site Work: Underwater Cleaning Robot In Action

At the port, the underwater cleaning robot showed its value quickly. The robot works from shore control or from a small support boat. Key on-site tasks were:

- Mapping the silt area and planning the route.

- Clearing near docks and intake screens.

- Collecting and depositing silt at safe locations.

The robot’s low-disturbance method lets the port keep operations running during work. Local operators found the controls easy and the job safe.

Customer Feedback And Results

After several weeks, the French client reported strong results:

- Efficiency: Sediment removal speed increased more than two times.

- Cost Savings: Labor and fuel bills dropped sharply.

- Environmental Gain: Water clarity improved, and habitat impact was small.

Operators liked the remote control and automatic features. City officials noted the system helps meet EU water quality rules. These results showed the robotic dredging machine worked well in a real municipal setting.

Advantages Of Our Underwater Dredging Robot

The YG underwater dredging robot brings clear advantages for cities and ports:

- High Efficiency: It can run long hours and cover targeted areas precisely.

- Environmentally Friendly: The robot reduces turbidity and limits suspended particles.

- Safety: No divers need to work underwater, cutting human risk.

- Smart Control: Remote operation and automatic monitoring make work simple.

This automated underwater dredging robot also scales for different projects. You can use one unit for small reservoirs or a fleet for large ports. YG can tune suction strength, pipe length, and navigation systems to each job.

Why Choose YG For Dredging Equipment For Sale

YG offers both strong machines and steady support. Our strengths are:

- Years of export work and many real cases.

- Ability to customize robot setup for local water and soil.

- Full technical support: remote help, spare parts, and on-site training.

- Competitive pricing and fast delivery options.

This project proves that an Underwater Dredging Robot can change municipal dredging. It cuts costs, raises safety, and protects the environment. If you need a custom dredging solution for ports, reservoirs, or waterways, contact YG Machinery. We will plan a dredging solution, share silt removal machine for sale details, and help you deploy a reliable robotic dredging machine for your site.

WhatsApp/WeChat/Phone: 86 138 3715 9132