A Tajikistan client ordered a complete wet wipe machine for sale from YG Machinery, received the equipment, completed the installation and commissioning, and has already started stable production, with very positive feedback on performance and operation.

Project Background And Local Constraints In Tajikistan

Tajikistan is a landlocked country in Central Asia. The local daily cleaning market relies heavily on imported wet wipes, which increases cost and limits supply stability.

The client’s goal was clear: build local wet wipes production capacity to reduce dependence on finished product imports and improve price competitiveness in the domestic market.

The project mainly serves the local daily cleaning market, including household cleaning and personal hygiene products sold through local distributors and small retail channels.

However, the client faced several realistic constraints that many emerging-market buyers share:

- The factory space was limited and based on a standard industrial workshop, not a large modern plant

- Initial order volumes were unstable, making ultra-high-speed fully automatic lines unsuitable

- Local technical workers had limited experience with complex automation systems

- The client relied heavily on after-sales support and remote technical guidance

These conditions are common among first-time investors in the wet wipes manufacturing industry. This case is designed to help similar buyers understand what kind of wet wipe machine for sale truly fits real production conditions, not ideal assumptions.

How The Tajikistan Buyer Evaluated Wet Wipe Machine Options

The client did not choose YG Machinery at the beginning. Instead, they compared different options in the market and evaluated risks carefully.

Comparison Of Three Main Equipment Options

The buyer mainly compared the following three solutions:

- Used wet tissue machine

Low upfront cost, but high risk in spare parts, hygiene standards, and long-term reliability - Ultra-high-speed fully automatic wet wipes production line

Strong capacity and automation, but far beyond the initial budget, and difficult to maintain locally - Mid-speed, modular wet wipe machine

Balanced investment, flexible configuration, and easier operation

After evaluation, the third option became the preferred direction.

Key Decision Factors In Equipment Selection

The client focused on practical issues rather than marketing claims:

- Support for multiple wipe formats, including single-piece and multi-piece packs

- Ability to upgrade later, such as adding a wet wipe packing machine or increasing speed

- Complexity of transportation and customs clearance

- Availability of English technical documents and remote commissioning support

This rational selection process reflects how many buyers in emerging markets approach a wet wipe manufacturing machine purchase.

Equipment Matching: Soft pack wet wipes machine

Based on the client’s real conditions, YG Machinery recommended a semi-automatic, mid-speed wet wipes production line instead of a one-size-fits-all solution.

Matched Equipment Configuration

The final solution included:

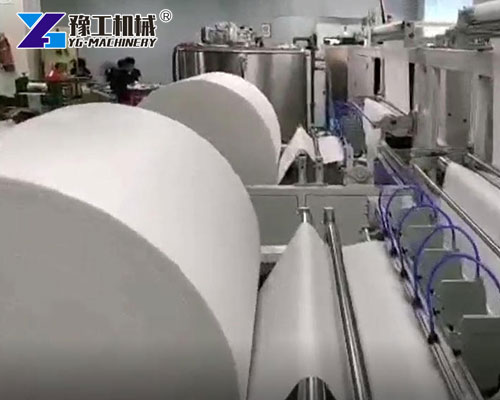

- A mid-speed wet wipes production line suitable for small to medium batches

- Integrated wet wipe forming and liquid dosing system for stable moisture control

- An independent wet wipe packing machine, making maintenance and future upgrades easier

This setup allowed the client to start production quickly while keeping operating risks low.

Realistic Compromises Made In The Project

To match local conditions, some compromises were necessary:

- Production speed was not the highest available on the market

- Manual assistance was needed during early-stage material loading and stacking

- Packaging formats were limited to mainstream specifications at the beginning

Why These Compromises Were Rational

These decisions were not weaknesses but strategic choices:

- Better suited for initial market testing

- Reduced downtime and maintenance pressure

- Matched local power supply and labor conditions

Delivery, Installation, And First-Stage Operation Feedback

Equipment Delivery Process

To reduce transportation risk, the wet wipe machine for sale was shipped in separate modules:

- Standardized disassembly and protective packaging

- Land transportation with multi-country transit, optimized for Central Asia routes

Installation And Commissioning Support

Due to distance and cost control, the project used:

- Remote video guidance from YG engineers

- A standardized commissioning checklist in English

- Step-by-step operator training during setup

Initial Production Feedback From The Client

After commissioning, the client reported:

- Stable daily operation without unexpected shutdowns

- Feasible operation by one or two workers

- Good compatibility with locally sourced raw materials, with no serious waste issues

As the client noted:

“I focused more on stable daily output than peak speed.”

This feedback reflects the real priorities of many small and medium-sized wet wipes manufacturers.

What This Tajikistan Case Teaches Other Wet Wipe Machine Buyers

This project offers several transferable lessons for potential buyers evaluating a wet wipe machine for sale:

- Small and mid-sized markets do not always need the fastest machines

- Early-stage projects should focus on:

- Ease of maintenance

- Technical support response speed

- Long-term expandability

How To Choose Between Full Automation And Modular Solutions

- Choose fully automatic lines when:

- Order volume is stable and large

- Skilled technicians are available locally

- Choose modular wet wipes machines when:

- Market demand is still growing

- Budget control and flexibility are priorities

These insights help buyers avoid costly mistakes and unrealistic expectations.

Who is this wet wipe machine designed for?

This type of wet wipe machine for sale is suitable for:

- Investors entering the wet wipes industry for the first time

- Buyers in Central Asia, the Middle East, and Africa

- Distributors planning to shift from OEM sourcing to in-house production

Rather than promising the lowest wet wipes machine price, this solution focuses on stability, control, and long-term usability.

WhatsApp/WeChat/Phone: 86 138 3715 9132