What Is A CNC Pipe Bending Machine?

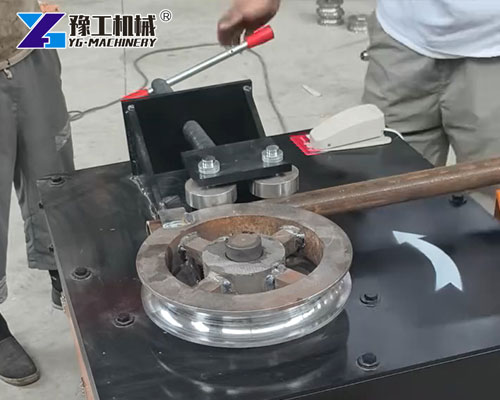

A CNC pipe-bending machine uses computer control to bend pipes and tubes with high precision and repeatability. It automates multi-step operations and removes manual errors. Many factories choose it when they need fast, accurate shaping of metal tubes.

Compared to standard pipe and tube benders or manual rollers, this CNC model is more accurate and faster. It reduces labor needs and improves quality consistency.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of CNC Pipe Bending Machine

| Model | YG-38 | YG-51 | YG-76 |

| Steel pipe dia.(mm) | 38 | 51 | 76 |

| Pipe thickness(mm) | 2 | 2-3.5 | 44656 |

| Bending angle Qty | 9 | 9 | 9 |

| Max. angle | 180 | 180 | 180 |

| Min. angle | 30 | 30 | 30 |

| Voltage(v) | 380 | 380 | 380 |

| Dimension(mm) | 920*650*850 | 920*680*850 | 1150*700*1000 |

| Weight(kg) | 210 | 260 | 420 |

Main Features Of CNC Pipe Bending Machine

The CNC pipe bending machine stands out for its automatic workflow and advanced precision.

Key features include:

- CNC Control Panel: Programmable angles, speed, and bend sequences.

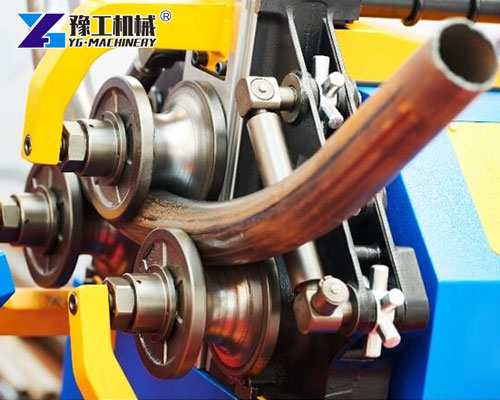

- Precision Bending Head: Works on pipes with diameters ranging from 10 mm to 76 mm.

- Multiple Axis Control: 3-axis or 4-axis models allow complex bends.

- Automatic Feeding System: Loads pipes automatically for volume production.

- Memory Function: Saves bend programs for repeat orders.

- High Repeat Accuracy: Variance less than ±0.5° per bend.

These bring fast cycle times and consistent results for tubing production lines.

Where CNC Pipe Bending Machine Excels

The pipe bending equipment fits many factory and workshop needs:

- Automotive Parts: Coolant lines, frames, roll cages.

- Furniture Industry: Curved steel frames for chairs and tables.

- Fitness Equipment: Bent pipes for frames and bars.

- HVAC Systems: Ducts and heating pipe bends.

- Metal Crafts: Sculptures, railings, display structures.

This automatic bender helps industries where precise and repeatable bends are essential.

Why Choose A CNC Pipe Bender?

A CNC pipe bender offers many advantages over manual or hydraulic models:

- Improved speed and production rate

- Precise and consistent bends every time

- Reduced labor and operator skill required

- Easy to switch between bend programs

- Less waste from trial-and-error bending

For businesses aiming to grow or streamline, this is a good investment.

CNC Pipe Bending Machine Price Factors

The CNC pipe bending machine price varies based on size and features:

- Axis Control: 3-axis cheaper, 4-axis more flexible

- Tube Range: Machines that bend larger tubes cost more

- Feeding System: Automatic loading adds value

- Software Package: Simple controllers are cheaper; advanced ones cost more

- Support and Warranty: Includes training and parts

YG Machinery offers competitive quotes with clear breakdowns and factory-direct pricing.

After-Sales And Support For CNC Machines

YG supports all CNC Pipe Bending Machine buyers with:

- 12-month warranty on major parts

- Online training videos

- Remote technical analysis and setup help

- Spare parts stock and prompt shipment

- Upgrades and software tuning assistance

Your machine stays running and productive from day one.

WhatsApp/WeChat/Phone: 86 138 3715 9132