A CNC Wire Bending Machine is designed for manufacturers who need accurate, repeatable, and efficient wire forming. As product designs become more complex, manual bending tools can no longer meet production requirements. Multi-axis CNC technology allows wire parts to be formed with high precision and stable quality.

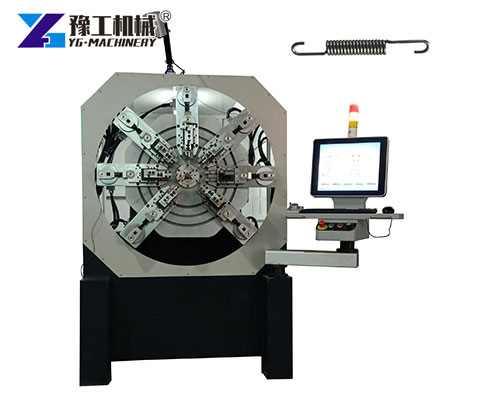

What Is A Multi-Axis CNC Wire Bending Machine

A multi-axis CNC wire-bending machine is an automated system that bends metal wire into precise shapes through CNC programming. The machine controls wire feeding, bending angle, and rotation direction using multiple servo-driven axes.

Compared with traditional bending tools, a CNC Wire Bending Machine offers better control, higher accuracy, and stable results for batch production. It is suitable for both simple and complex wire forming tasks.

Multi Axis Wire Bending Machine Structure And Core Components

A multi-axis wire-bending machine is composed of several key modules that work together to ensure stable operation and precise forming.

Main structural parts include:

- Multi-axis servo system for bending and rotation

- CNC control system for programming and monitoring

- Automatic wire feeding and straightening module

This structure allows CNC wire forming equipment to maintain consistent performance during long production cycles.

Product Parameters Of CNC Wire Bending Machine

YG CNC wire bending machines are available in different configurations to meet various production needs.

| Model | 20-10 | 25-10 | 30-12R | 35-10 | 35-12R | 45-12R | 50-12R | 60-12R | 80-12R | 100-12R | 120-12R |

| Wire dia(mm) | 0.2-2.0 | 0.2-2.5 | 0.4-3.0 | 0.8-3.5 | 0.8-3.5 | 1.2-4.5 | 1.2-5.0 | 2.0-6.0 | 3.0-8.0 | 4.0-10.0 | 5.0-12.0 |

| Max. wire feeding value | 10000 | ||||||||||

| Min. wire feeding value | 0.01 | ||||||||||

| Max. wire feeding speed | 120 | 120 | 120 | 120 | 80 | 80 | 80 | 80 | 80 | 60 | 60 |

| Max. wire feeding length | Unlimited | ||||||||||

| Axis number | 10 | 10 | 12 | 10 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Total output power of servo motors | 6.6KW | 10.0KW | 13.3KW | 14.2KW | 17.6KW | 21.8KW | 22.9KW | 39.8KW | 55.0KW | 86.3KW | 96.6KW |

| Input power supply | 380/50/3 | ||||||||||

| Program storage | 3000 | ||||||||||

| Compressor air pressure | 5-6 | ||||||||||

| Probe number | 3 | ||||||||||

| Overall length(mm) | 1100 | 1200 | 1500 | 1400 | 2200 | 2650 | 2650 | 3500 | 3500 | 4200 | 4300 |

| Overall width(mm) | 800 | 1250 | 1250 | 1550 | 1550 | 1800 | 1800 | 2150 | 2150 | 2350 | 2500 |

| Overall height(mm) | 1550 | 1760 | 1860 | 1800 | 1850 | 2070 | 2070 | 2150 | 2150 | 2580 | 2650 |

| Net weight(kg) | 700 | 980 | 1500 | 1600 | 2500 | 4100 | 4500 | 7000 | 7200 | 12000 | 15000 |

Each CNC Wire Bending Machine can be configured based on material type and product complexity.

Working Principle Of CNC Wire Bending Machine

The working principle of a CNC wire bending machine is based on programmed automation. After the program is set, the machine completes the forming process without manual adjustment.

The forming process includes:

- Automatic wire feeding and straightening

- Controlled bending by servo-driven tools

- Wire rotation for multi-directional shaping

- Continuous forming according to CNC instructions

This process ensures stable quality and repeatable results.

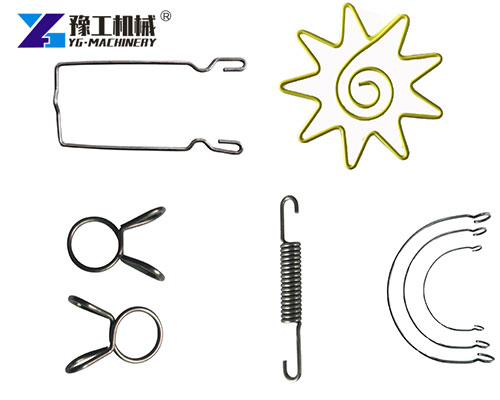

3D Wire Bending Machine For Complex Wire Shapes

A 3D wire bending machine is designed to produce complex wire shapes that require bending in multiple directions. Multi-axis movement allows the wire to be rotated and bent accurately during one continuous process.

This capability is especially useful for:

- Complex industrial wire parts

- Customized wire designs

- High-precision wire components

It expands production possibilities without increasing labor cost.

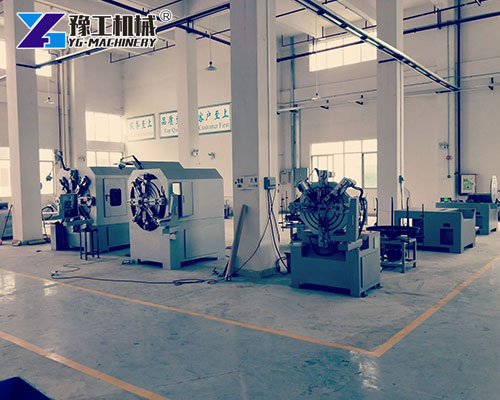

CNC Wire Forming Equipment Advantages For Industrial Production

As professional CNC wire forming equipment, YG machines focus on reliability and efficiency for industrial use.

Main advantages include:

- High precision and repeatable bending results

- Stable operation during continuous production

- Lower labor cost through automation

- Support for complex wire designs

These advantages help manufacturers improve productivity and product quality.

Difference Between CNC Wire Bending Machine And Traditional Wire Tools

Traditional wire bending tools rely on manual operation and mechanical adjustment. This often leads to inconsistent quality and low production efficiency.

Compared with traditional tools, a CNC Wire Bending Machine provides:

- Higher forming accuracy

- Faster setup and changeover

- Reduced material waste

- Better consistency for batch orders

This makes CNC technology more suitable for modern manufacturing.

Industrial Wire Shaping Machine Applications Across Industries

An industrial wire shaping machine is widely used in many industries that require accurate wire parts.

Automotive Industry

- Clips

- Brackets

- Spring components

Electronics Industry

- Connector pins

- Wire frames

Hardware Industry

- Industrial fasteners

- Decorative wire components

Medical Device Industry

- Small precision wire parts

These applications require stable quality and precise forming.

How To Choose The Right Multi-Axis CNC Wire Bending Machine

Selecting the right machine depends on your production needs and product requirements.

Important factors include:

- Wire diameter and material

- Shape complexity

- Production volume

- Required automation level

Choosing suitable CNC wire forming equipment helps reduce cost and improve efficiency.

Frequently Asked Questions About CNC Wire Bending Machine

What materials can be processed?

Carbon steel, stainless steel, aluminum, copper, and alloy wire.

Is the machine easy to operate?

Yes. The CNC control system is user-friendly and easy to learn.

Can the machine be customized?

Yes. Machine configuration can be adjusted based on wire products.

How To Start Using Our CNC Wire Bending Machine

YG supports customers from machine selection to operation.

The process includes:

- Requirement analysis and model recommendation

- Machine customization and testing

- Delivery and installation guidance

- Operator training and after-sales support

This ensures smooth production startup and long-term operation.

WhatsApp/WeChat/Phone: 86 138 3715 9132