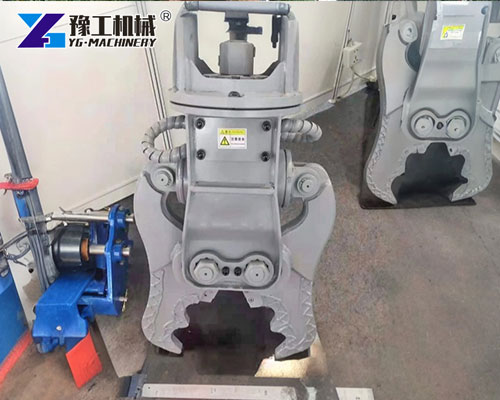

The concrete crusher attachment turns a standard excavator into a high‑powered demolition and recycling tool. By crushing reinforced concrete on‑site, contractors save hauling fees, reduce landfill waste, and generate reusable aggregate—all with the same carrier already on the job.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Key Advantages Of Concrete Crusher Attachments

- One‑Pass Size Reduction – 250 kN jaw force fractures rebar‑reinforced concrete in seconds.

- Integrated Rebar Cutter – Hardened shear blades slice metal cleanly, leaving ready‑to‑sell scrap.

- 360° Hydraulic Rotation – Operators grab, crush, and place without repositioning the boom.

- Low Noise & Dust – Serrated jaw profile cracks material instead of hammering, achieving ≤95 dB at cab.

- Quick‑Change Teeth – Bolt‑on jaw plates swap in 15 minutes, slashing downtime.

Using a concrete crusher attachment for excavator, contractors typically recover ROI within eight months thanks to reduced haul‑off and purchased stone.

Applications of a Concrete Crusher Excavator

The versatility of a concrete crusher excavator attachment makes it an indispensable tool for a wide array of projects, such as:

- Demolition Projects: Efficiently crushing concrete structures during demolition, preparing the site for redevelopment.

- Road Construction and Repair: Recycling old asphalt and concrete for use as base material in new road construction or repairs.

- Bridge and Infrastructure Projects: Processing concrete debris from bridge demolitions and infrastructure upgrades.

- Land Clearing and Site Preparation: Crushing concrete and other hard materials encountered during land clearing operations.

- Recycling Centers: Processing incoming concrete waste from various sources, creating valuable recycled aggregate.

The Working Principle of a Concrete Crusher Attachment

YG’s concrete crusher attachment for excavator operates based on a powerful hydraulic crushing mechanism. Here’s a simplified breakdown of the process:

- Hydraulic Power: The excavator’s hydraulic system powers the crusher attachment, providing the necessary force for crushing.

- Jaw Movement: The attachment features a robust crushing jaw, typically made of high-strength steel. One jaw is usually fixed, while the other moves back and forth or pivots, driven by hydraulic cylinders.

- Material Infeed: Concrete rubble or other material is fed into the crushing chamber between the jaws.

- Crushing Action: The hydraulic force exerted by the moving jaw crushes the material against the fixed jaw. The size of the crushed material is determined by the gap setting between the jaws, which can often be adjusted.

- Discharge: The crushed material falls out of the bottom of the crushing chamber, ready for reuse or further processing.

Key Considerations When Choosing the Right Concrete Crusher

Selecting the ideal concrete crusher attachment for your excavator is crucial for maximizing efficiency and achieving optimal results. Consider the following factors:

- Excavator Size and Hydraulic Capacity: Ensure the crusher attachment is compatible with the weight class and hydraulic flow of your excavator. YG offers models designed for various excavator sizes.

- Crushing Force and Capacity: Evaluate the type and volume of concrete you will be processing to determine the required crushing force and throughput capacity of the attachment.

- Jaw Opening Size: The jaw opening dictates the maximum size of concrete pieces that can be fed into the crusher. Choose a size appropriate for your typical material.

- Crusher Type: Different types of concrete crushers exist (e.g., jaw crushers, rotary crushers). YG primarily offers robust jaw-type crushers known for their power and reliability in concrete demolition.

- Durability and Maintenance: Look for a crusher attachment built with high-quality materials and a design that allows for easy maintenance and replacement of wear parts.

- Noise and Vibration Levels: Consider the noise and vibration generated by the crusher, especially if operating in noise-sensitive environments.

- Safety Features: Ensure the attachment incorporates safety features to protect the operator and surrounding personnel.

Beyond Concrete Crushers: Other YG Excavator Demolition Attachments

In addition to our high-performance concrete crusher attachment for excavator, YG offers a comprehensive range of other excavator demolition attachments designed to enhance your versatility and productivity on the job site. These include:

- Hydraulic Breakers: Powerful tools for breaking up concrete, rock, and other hard materials.

- Demolition Shears: Efficiently cutting steel structures, pipes, and other metal components.

- Grapples: Versatile attachments for handling and sorting various types of demolition debris.

- Rippers: Used for breaking up hard ground, asphalt, and other compacted materials.

- Pulverizers: Designed for secondary crushing and pulverizing of concrete and masonry.

By offering a wide array of high-quality demolition attachments, YG provides comprehensive solutions to meet the diverse needs of the construction, demolition, and recycling industries.

WhatsApp/WeChat/Phone: 86 138 3715 9132