The Concrete Laser Leveling Machine is a high-precision construction tool used to level and finish concrete floors. It uses laser-guided technology to ensure a smooth, even surface, minimizing manual labor and reducing errors. Whether for large-scale industrial projects or commercial floor installations, this machine improves work efficiency, surface quality, and construction speed.

YG offers a wide range of laser leveling machines designed to meet different construction needs. The equipment is widely used in warehouses, factories, parking lots, shopping centers, and other large flat concrete areas.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Concrete Laser Leveling Machine Parameters

| Model | YGJX31 | YGJX32 | YGJX33 | YGJX34 |

| Engine | ||||

| Model | Generator set | GX390 Electric start | GX390 Electric start | GX390 Electric start |

| Power | 2.0kW | 13hp/3600rpm | 13hp/3600rpm | 13hp/3600rpm |

| Fuel tank (L) | 14.5 | 6.5 | 6.5 | 6.5 |

| Running device | ||||

| Drive | Motor | Hydraulic motor | Hydraulic motor | Hydraulic motor |

| Running mode | Infinitely variable speed | Handle control, stepless speed | Handle control, stepless speed | Handle control, stepless speed |

| Running speed(m/min) | 0-36 | 0-45 | 0-65 | 0-45 |

| Suggest working speed(m/min) | 5 | 5 | 5 | 5 |

| Screed head | ||||

| Type | Self-leveling | Electric control, self-leveling | Self-leveling | Hydraulic control, self-leveling |

| Width | 2500mm | 2500mm | 2500mm | 2500mm |

| Exciting force | 500N | 500N | 500N | 500N |

| Vibration frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Laser control system | ||||

| Control type | Microcomputer laser scan | Microcomputer laser scan | Microcomputer laser scan | Microcomputer control |

| Operation mode | Walk-behind | Walk-behind | Walk-behind | Walk-behind |

| Forward and reverse | Handgrip control, stepless speed-walking | Hydraulic control | Handgrip control, stepless speed-walking | Hydraulic control |

| Size and weight | ||||

| Working size(mm) | 2758*2622*1980 | 2740×2659×1980 | 2578×2643×1980 | 2780*2622*1980 |

| Weight(kg) | 295 | 365 | 380 | 410 |

Types of YG Concrete Laser Leveling Machines

YG manufactures multiple categories of Concrete Laser Screed equipment, allowing users to choose the best solution for their project:

- Walk-Behind Concrete Laser Leveling Machine

- Compact and easy to maneuver

- Ideal for small or narrow areas

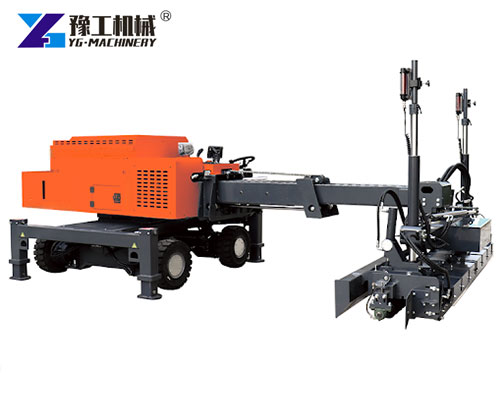

- Ride-On Laser Leveling Machine

- Suitable for large construction sites

- High efficiency with powerful motors

- Telescopic Boom Laser Screed

- Extended reach for broader surfaces

- Greater leveling area with fewer repositionings

- Remote-Controlled Concrete Laser Screed

- Improved safety and convenience

- Perfect for difficult or hazardous environments

Each type serves a different scenario, helping users maintain consistent surface accuracy and reduce fatigue during long hours of operation.

Key Features of Concrete Laser Leveling Machine

YG’s laser-guided concrete leveling machine stands out for its practical features, which are designed to enhance concrete floor quality and operator performance:

- High-Precision Laser System: Automatically adjusts height to maintain an even level.

- Real-Time Feedback: Ensures accurate data transmission and consistent leveling.

- Heavy-Duty Vibrator: Helps compact and smooth the concrete effectively.

- Strong Frame Design: Durable and weather-resistant for long-term use.

- User-Friendly Interface: Easy to operate even for new users.

These features ensure not only excellent leveling performance but also improved job site safety and faster project completion.

How Does a Concrete Laser Screed Work?

The Concrete Laser Screed machine operates using a combination of laser transmitters, sensors, and mechanical components that work together to level wet concrete. Here’s how it works:

- Laser Transmitter Setup

- A fixed laser transmitter sends signals across the work area.

- Receiver and Sensor Activation

- The screed head, equipped with a laser receiver, detects the beam height.

- Automatic Adjustment

- Based on the laser signal, the screed automatically adjusts its elevation.

- Vibrating Blade Operation

- A vibrating blade consolidates and levels the surface while moving forward.

- Control System Feedback

- The system continuously receives and adjusts to real-time feedback for accuracy.

This intelligent leveling system eliminates the need for guide rails or manual correction, making it ideal for large flat areas.

Applications of Laser-Guided Concrete Leveling Machine

The laser-guided concrete leveling machine is used across various sectors where large, flat concrete surfaces are required. Key application areas include:

- Industrial floors

- Commercial plazas

- Warehouse construction

- Airport terminals

- Large parking lots

- Sports arenas

Because of its efficiency and leveling precision, it is especially valuable in time-sensitive or large-area projects where manual work would be too slow or inconsistent.

Advantages of Concrete Laser Leveling Machines:

- Superior Precision: Achieve exceptional flatness/levelness (high F-numbers), eliminating uneven surfaces critical for industrial/commercial use.

- Increased Speed & Productivity: Automate leveling, drastically accelerating large pours compared to manual methods, reducing project timelines.

- Reduced Labor & Costs: Minimize crew size on the slab, lowering labor expenses and freeing skilled workers. Long-term savings outweigh the initial investment.

- Enhanced Concrete Quality: Integrated vibration consolidates concrete, increasing density, strength, and long-term durability while reducing cracks.

- Improved Safety: Fewer workers on wet concrete and remote operation options minimize safety risks.

- Versatility: Various models (walk-behind, ride-on, remote) suit diverse project scales and complexities.

Concrete Laser Screed Price: YG Manufacturer

When considering the acquisition of a Concrete Laser Screed, understanding the pricing structure and value proposition from a reputable manufacturer like YG is essential. The price of a Concrete Laser Screed can vary significantly based on several factors, including the machine type, its size, the level of automation (e.g., remote control), and the inclusion of advanced features and technologies.

YG, as a dedicated manufacturer, is committed to providing high-quality, reliable, and competitively priced Concrete Laser Screed machines. Our goal is to offer solutions that deliver an excellent return on investment through enhanced efficiency, superior concrete quality, and reduced operational costs for our customers.

WhatsApp/WeChat/Phone: 86 138 3715 9132