A Concrete Shot Blaster is a fast and strong machine. It cleans and roughens concrete surfaces. Many builders use it for epoxy floors, road repair, and concrete maintenance. The machine operates more efficiently than manual grinding. It gives a clean, open surface. This helps paint and coatings stick better. Good machines save time and lower costs on big jobs.

What Is A Concrete Shot Blaster

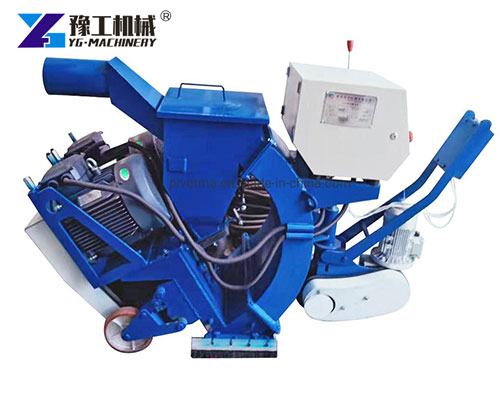

A concrete shot blaster uses a spinning wheel and steel shots. The shots hit the floor at high speed. This breaks old paint, laitance, and soft concrete. The result is a textured, clean surface ready for a new coating. The main components are the blast wheel, shot pot, dust box, and collection system. Some models have a hopper to catch debris. Operators walk behind or drive the machine. The work is fast and steady.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Parameters of Concrete Shot Blaster

| Model | YG550/600(Double) | YG-850(Double) | |

| Shot Blasting Wheel Diameter | 200 mm | ||

| Working width | 550/600 mm | 800 mm | |

| Walking speed | 0.5~33 m/min | ||

| Concrete surface cleaning efficiency | ≥400 m2/h | ≥600 m2/h | |

| Steel plate surface cleaning efficiency | 75-100 m2/h | 100-160 m2/h | |

| Dust connection pipe diameter | 150 mm | ||

| Suggest the diameter of steel balls | 1.5-1.8 mm | ||

| Steel pill consumption | 10 g/m2 | ||

| Supporting the dust collector | Eight-core automatic backflush vacuum cleaner | ||

| Shot wheel motor | Power consumption | 11*2 kW | 15*2 kW |

| Input Current | ≤ 22*2 A | ≤ 28*2 A | |

| Walking motor | Power consumption | 1.5 kW | |

| Input Current | 3 A | ||

| Size (mm) | 1950*720/775*1400 | 1950*1020*1550 | |

| Weight | 570 kg | 700kg | |

| Power connection requirements | 400V, 50Hz, 100A, CEE socket | ||

Advantages Of Using A Floor Shot Blaster

A floor shot blaster gives many benefits on-site:

- Fast Area Coverage: One pass can treat large floors.

- Better Adhesion: The rough surface helps epoxy and paint stick.

- Less Dust: Models with dust collection cut airborne dust.

- Low Water Use: It does not need water like wet grinding.

- Long Life: Steel shot reused many times, lowering cost.

Using a floor shot blaster means fewer repairs later. It also reduces worker fatigue and cleanup time.

Applications of Shot Blasting Concrete Floor

Shot blasting concrete floor is used in many scenes:

- Industrial Workshops: Remove oil, paint, and weak concrete.

- Parking Lots: Clean and profile asphalt or concrete before resurfacing.

- Bridges and Tunnels: Prepare surfaces for protective coatings.

- Epoxy and Resin Floors: Create a strong bond for coatings.

Shot blasting works well where quality and speed matter. It is good for both new work and repair jobs.

How To Choose The Right Machine

Pick the best floor shot blaster with simple checks:

- Area Size: Big areas need higher production.

- Coating Type: Some coatings need a deeper profile.

- Dust Control: Choose a machine with good collection if indoors.

- Portability: Move smaller machines by hand. Big machines need a truck.

- Parts and Service: Check local support and spare part supply.

A short trial or demo can help decide. Ask the supplier for sample results on similar floors.

Why Choose YG Concrete Shot Blaster

YG makes reliable Concrete Shot Blaster equipment for many sites. Our reasons to buy:

- Many Models: From small to heavy-duty machines.

- Durable Parts: Wear parts made for long life.

- Dust Control Options: Built-in collectors or external filters.

- Global Cases: Used in factories, parks, and airports.

- After-Sales Support: Spare parts and service guidance.

YG machines match both quality and price. This helps contractors meet deadlines and budget.

Safety And Operation Tips

Use a shot blaster safely with these simple steps:

- Wear eye and ear protection.

- Use a dust mask or respirator if dust is present.

- Check the shot level and wheel before starting.

- Move at a steady speed for an even profile.

- Clean and inspect the machine after each job.

Good training keeps crews safe and machines working longer.

Maintenance And Spare Parts

Keep the machine running with basic care:

- Change worn blades and liners on time.

- Check bearings and seals each week.

- Clean dust filters and empty collection boxes.

- Use the proper steel shot grade to extend life.

Easy maintenance lowers cost and avoids unwanted downtime.

If you need a strong Concrete Shot Blaster for floors or large areas, contact YG Machinery today. Tell us your floor size, coating type, and dust rules. We will recommend the right floor shot blaster or heavy concrete floor shot blasting machine, and give a clear price. Get fast quotes and technical support for your project now.

WhatsApp/WeChat/Phone: 86 138 3715 9132