Concrete Wall Saw Cutting Machine For Demolition Projects

Demolition work often involves cutting thick concrete structures with embedded steel bars. These tasks are difficult, time-consuming, and risky when using traditional tools. A Concrete Wall Saw Cutting Machine is designed to handle these challenges with higher safety, accuracy, and efficiency.

In modern demolition projects, contractors must control vibration, dust, and noise while keeping nearby structures safe. Manual cutting tools and heavy breakers often cause uncontrolled damage. This is why professional wall saw systems have become essential equipment for concrete demolition work.

A wall saw allows operators to cut concrete structures in a planned and controlled way. It improves job quality while reducing labor intensity and project downtime.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Why Demolition Projects Need A Concrete Wall Saw Cutting Machine

Traditional demolition methods rely heavily on breakers, jackhammers, or handheld cutters. While these tools are still used, they have clear limits in professional projects.

Limits Of Traditional Demolition Methods

- Difficult to control cutting lines and depth

- Strong vibration that may damage nearby structures

- Slow cutting speed on reinforced concrete

- High dust levels and poor working conditions

In contrast, a Concrete Wall Cutting Machine offers a safer and more efficient solution for demolition contractors.

Core Advantages In Demolition Work

- Precise cutting to avoid over-breaking concrete

- Low vibration, reducing structural impact

- High cutting efficiency, saving time and labour

- Cleaner operation, easier debris management

For controlled demolition, especially in urban areas, wall saw systems are no longer optional equipment.

Parameters of Concrete Wall Saw Cutting Machine

| Hydraulic Oil Pump | Model | YG 600 | YG 700 |

| Max. power | 25KW | 30KW | |

| Motor cooling method | Air cooling | water cooling | |

| Rated voltage | 380V 50HZ | 380V-420V 50HZ-60HZ | |

| Pressure stages | 3 | 3 | |

| Max. operating pressure | 200bar/20Mpa | 210bar/21Mpa | |

| Oil flow rate | 30-80L/min | 40-100L/min | |

| Dimensions | 600mm*650mm*1050mm | 500mm*520mm*1100mm | |

| Weight | 220kg | 140kg | |

| WallSaw | Saw blade diameter range | 800-1400mm | 800-1600mm |

| Cutting depth | 620mm | 730mm | |

| Max. working pressure | 180bar/18Mpa | 200bar/20Mpa | |

| Max. oil flow rate | 100l/min | 100l/min | |

| Gearing | Gear | Gear | |

| Rotation speed | 450/950/1300Rpm | 450/850/1200Rpm | |

| Dimension | 400mm*420mm*400mm | 400mm*420mm*400mm | |

| Weight | 38kg | 39kg |

How A Concrete Wall Saw Cutting Machine Works In Demolition

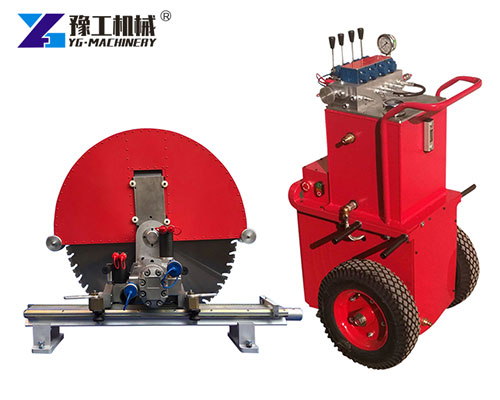

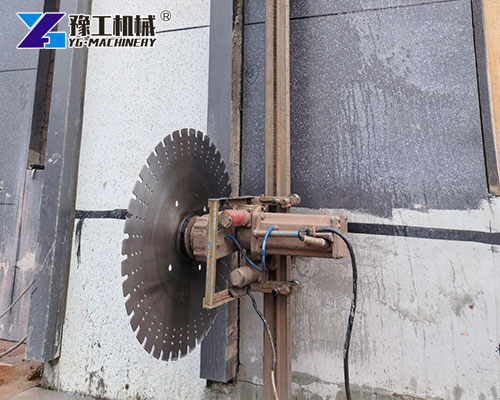

A wall saw cutting machine is mounted on a stable guide rail fixed to the concrete surface. The saw blade moves along the rail to achieve straight and deep cuts.

Basic Working Components

- Guide rail system for accurate movement

- Diamond saw blade for reinforced concrete

- Drive unit (hydraulic or electric)

- Water cooling system to reduce dust and heat

Typical Demolition Cutting Process

- Fix guide rails to the concrete surface

- Set cutting depth and direction

- Start cutting with stable blade movement

- Remove cut concrete sections safely

This method works well for:

- Reinforced concrete walls

- Floor slabs and beams

- Shear walls and load-bearing structures

Key Features Of A Concrete Wall Saw Cutting Machine For Demolition Work

A professional wall saw system combines power, control, and safety. Below are the main features required for demolition applications:

- High cutting depth for reinforced concrete

- Powerful motor or hydraulic drive system

- Stable guide rail for straight cutting

- Smooth and clean cutting surface

- Low vibration and controlled noise output

- Compatibility with large-diameter saw blades

These features allow demolition contractors to complete jobs faster while maintaining structural safety.

Demolition Applications of the Wall Saw

Wall saw systems are widely used across different demolition scenarios:

- Building renovation and structural removal

- Door and window openings during demolition

- Bridge and infrastructure dismantling

- Industrial concrete structure removal

These applications require controlled cutting rather than brute force, making wall saws essential demolition equipment.

How To Choose The Right Concrete Wall Saw Cutting Machine For Demolition

Selecting the right wall saw depends on job conditions and project requirements.

Key Selection Factors

- Concrete thickness and reinforcement level

- Working environment: indoor or outdoor

- Power supply and voltage availability

- Cooling system and water access

Practical Advice For Contractors

- Choose Hydraulic Wall Saws for heavy outdoor demolition

- Select High Frequency Wall Saws for indoor or urban work

- Ensure blade size matches cutting depth needs

The right selection improves safety and reduces operating costs.

Why Choose Our Concrete Wall Saw Cutting Machine

YG focuses on manufacturing wall saw systems designed for demanding demolition environments.

Our Manufacturing Strengths

- Specialisation in hydraulic and high-frequency wall saws

- Stable performance for high-intensity demolition work

- Support for OEM and customised solutions

- Export experience across Europe, North America, and other regions

Our equipment is built for contractors who need reliable and efficient concrete cutting solutions.

Request A Quote For Your Demolition Project

Demolition projects require accurate, safe, and efficient cutting solutions. A Concrete Wall Saw Cutting Machine helps contractors reduce risks, improve efficiency, and control project costs.

Contact YG today to get technical support and pricing tailored to your demolition requirements.

WhatsApp/WeChat/Phone: 86 138 3715 9132