What Is A Concrete Wire Saw?

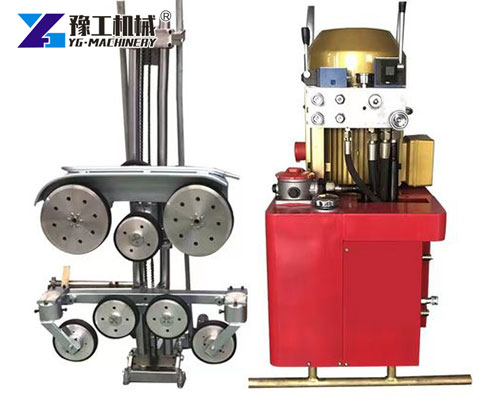

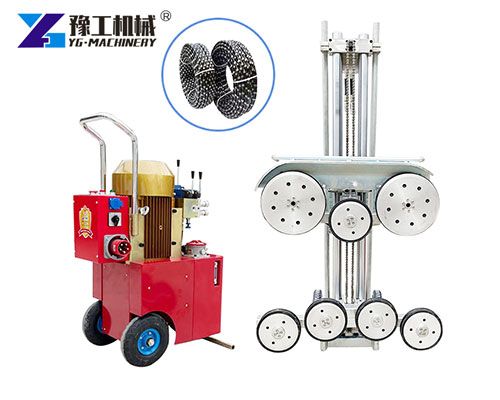

A Concrete Wire Saw is a cutting machine that uses a loop of diamond wire to cut thick or reinforced concrete. The wire moves at high speed around a drive wheel, allowing it to cut concrete, steel, and rock with very little vibration. This makes the machine suitable for many construction and demolition tasks.

Concrete wire saws are often used when a project needs a clean cut, quiet operation, or when traditional blade saws cannot reach the cutting area.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Product Parameters of Concrete Wire Saw

Our concrete wire saw comes with several standard technical parameters that help contractors handle small and large jobs.

| Wire Saw Wheel Parameters | Hydraulic Pump Station Parameters | ||

| Wire Drive Mode | hydraulic | Rated Output Power | 22/25KW |

| Model Type | HM-40/80 | Working Voltage | 380v 50Hz |

| Minimum Input Power | 25HP/33HP | Hydraulic Pump Station | Gear pump |

| Output Shaft Speed | 350/940/1300r/min | Motor Working Floe | 40-100L/min |

| Maximum Wire Length | 18m | Working Pressure | 15-20Mpa |

| Feeding Method | Fully hydraulic | Oil Tank Volume | 16L |

| Wire Saw Wheel | 64kg | Weight | 98kg |

| Motor Weight | 13kg | Dimension(mm) | 650*550*1150 |

| Cutting Type | Transverse and longitudinal cutting | ||

These parameters make the machine stable and suitable for long working hours on different construction sites.

Main Advantages Of Using A Concrete Wire Saw

A concrete wire saw is preferred by many contractors because it offers several clear advantages:

- Cuts very thick or reinforced concrete with ease

- Produces little vibration, protecting the building structure

- Works well in narrow spaces and underwater conditions

- Leaves a smooth cutting surface, which saves finishing time

- Reduces noise and dust when compared with blade cutting

For projects where safety and precision matter, a wire saw is one of the most reliable options in the market.

YG Concrete Wire Saw Product Features

YG concrete wire saw is designed to meet professional construction needs. It offers steady performance and strong cutting power. Key features include:

- High-power motor for all-day cutting

- Durable diamond wire that lasts longer than standard wires

- Automatic tension control for a smoother cutting line

- A water cooling system to reduce heat and protect the wire

- Strong frame structure that keeps the machine stable

- Easy setup, simple operation, and low maintenance

These features help contractors complete heavy-duty jobs faster and with better results.

Diamond Wire Saw Machine Applications In Real Construction Projects

Because a concrete wire saw can work on almost any type of concrete or steel structure, it is widely used in many real projects:

Bridge Demolition

Contractors use the machine to cut bridge piers, beams, and road decks. It can handle thick concrete and steel bars without slowing down.

Building Openings And Expansion

When buildings need new doors, windows, or larger openings, the wire saw cuts clean lines with minimal damage around the edges.

Cutting Large Concrete Blocks

It is useful for breaking down big concrete blocks into smaller pieces for safe removal.

Underwater Foundation Removal

The machine works well underwater because the diamond wire is cooled by water naturally, making it safer and more stable.

These examples show how flexible and powerful a wire saw is for modern construction.

Why Contractors Choose Our Diamond Wire Saw Machine

Contractors across many countries choose our diamond wire saw machine because of several important advantages:

- Long Diamond Wire Life: Our wire lasts longer and reduces replacement costs.

- Easy Installation And Low Maintenance: Operators can set it up quickly and keep it running with simple daily checks.

- Strong Cutting Ability: It cuts concrete, steel, and rock with high efficiency.

- Reliable Quality Control: Every machine is tested before shipping.

- Global Support: We offer fast after-sales service and spare parts delivery.

These reasons make our machine a trusted choice for demanding construction jobs.

How To Choose The Right Concrete Wire Saw

Choosing the right construction wire saw machine helps improve working speed and safety. Here are some simple tips:

- Choose The Wire Type Based On Hardness: Harder concrete needs stronger diamond beads.

- Match Motor Power To Project Size: Large bridges and foundations need a higher-power motor.

- Follow Safety Tips: Wear protective gear, keep the wire wet, and check the tension before cutting.

- Use Recommended Accessories: Extra pulleys, guiding wheels, and spare diamond wires can help improve cutting efficiency.

Following these steps helps ensure smooth work and better cutting results.

Frequently Asked Questions

Q1: Can a concrete wire saw cut reinforced concrete?

Yes. It can cut any amount of steel reinforcement.

Q2: Does the wire overheat during cutting?

No. The water cooling system keeps the wire at a safe temperature.

Q3: What materials can the machine cut?

Concrete, steel, rock, and mixed materials.

Q4: How long does a diamond wire last?

It depends on the material hardness, but our wire lasts longer than standard wires.

Contact Us For Concrete Wire Saw Solutions

If you need a powerful and efficient concrete wire saw for your next project, our team can help you choose the right model and wire type.

We provide fast shipping, technical support, and competitive pricing for all construction needs.

WhatsApp/WeChat/Phone: 86 138 3715 9132