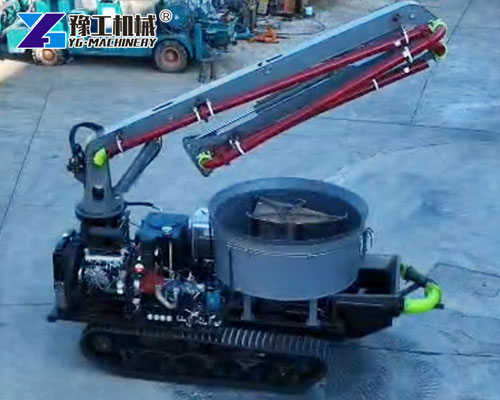

The Crawler Type Mixing Pump is a powerful and mobile solution designed for delivering concrete in hard-to-reach or rough terrain areas. Combining mixing and pumping functions in one compact unit, this equipment is especially suitable for remote projects where traditional concrete transport methods fall short. With its crawler chassis, it offers strong traction and mobility, making it ideal for mountain roads, tunnels, or muddy construction sites.

WhatsApp/WeChat/Phone: 86 138 3715 9132

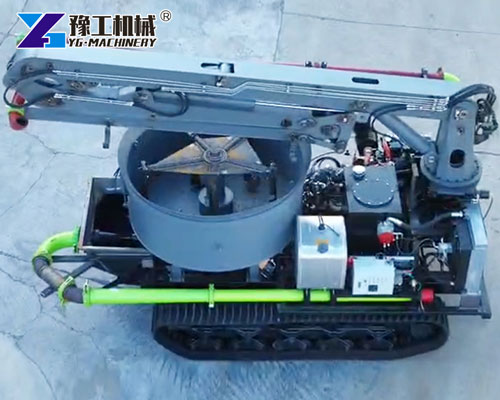

Parameters of Crawler Type Mixing Pump for Sale

| Model | YG-15 Line Pump with Mixer |

| Max Theoretical Concrete Output | 40m³/h |

| Mixer | 2 cubic meter mixer |

| Engine Power | 85 kW diesel engine |

| Chassis | All-terrain crawler chassis |

| Max Theoretical Conveying Distance (Horizontal Distance/Vertical Height) | 260m/120m |

| Overall Dimension | 4000×1500×1550mm |

| Total Weight | 17 tons |

Crawler Type Pan Mixer Pump Truck: Performance Features

The Crawler Type Pan Mixer Pump Truck combines powerful mixing capacity with stable pumping performance. This all-in-one machine reduces the need for additional transport equipment and offers the following advantages:

- Integrated System: Mixer and pump in one machine saves space and time.

- Crawler Mobility: Stable movement over mud, sand, gravel, and slopes.

- Efficient Mixing Drum: Ensures even blending of cement, gravel, and additives.

- Hydraulic Control System: Precise operation and reduced labor.

- Small Footprint: Operates in tight spaces and complex terrains.

The Crawler Type Pan Mixer Pump Truck is especially favored by contractors who work in rugged or decentralized construction sites.

Application Scenarios Of The Crawler-Type Mixing Pump

The Crawler Type Mixing Pump serves a wide range of construction scenarios where mobility and efficiency are critical. It is particularly effective in the following environments:

- Rural Infrastructure Projects: Road paving, small bridge foundations, and village house construction.

- Tunnels and Mines: Perfect for underground construction with limited access.

- Slope and Hill Work: Its crawler system easily handles steep or uneven terrain.

- Urban Renovation Projects: Compact size makes it suitable for narrow streets and restricted areas.

- Disaster Relief and Emergency Work: Delivers concrete quickly and reliably where normal trucks cannot go.

Features Of Crawler-Type Mixing Pump

The Crawler Type Mixing Pump is designed with the needs of job-site flexibility and durability in mind. Its core features include:

- Mobility: Tracks provide reliable movement over all types of terrain.

- Compact Design: Ideal for places where larger concrete trucks cannot reach.

- Strong Pumping Pressure: Allows concrete to be pumped over long distances.

- Low Energy Consumption: Efficient engine design reduces fuel use.

- Easy Maintenance: Modular components are easy to clean and replace.

These features help improve on-site productivity while minimizing labor costs.

Step-by-Step Guide to Operating Your Crawler-Type Mixing Pump

Operating the Crawler Type Mixing Pump involves the following general steps. Always refer to the specific operation manual provided with your equipment for detailed instructions and safety guidelines:

- Preparation: Ensure the work area is clear and level as much as possible. Check all fluid levels (hydraulic oil, engine oil, coolant) and ensure the machine is in good working order.

- Material Loading: Load the required aggregates, cement, and water into the mixing drum according to the specified mix design.

- Mixing Operation: Start the mixing system and allow the materials to mix thoroughly until the desired concrete consistency is achieved.

- Positioning for Pumping: Drive the Crawler Type Mixing Pump to the desired pumping location, ensuring stable positioning.

- Boom Deployment: If equipped with a Boom Concrete Pump, carefully deploy the boom to the required reach and height.

- Pumping Operation: Engage the pumping system and begin pumping the mixed concrete to the designated placement area. Monitor the pumping pressure and flow rate.

- Material Discharge: Ensure the concrete is discharged evenly and according to the placement requirements.

- Cleaning: After use, thoroughly clean the mixing drum, pump, and boom (if applicable) to prevent concrete buildup and ensure the longevity of the machine.

- Maintenance: Perform regular maintenance checks and servicing as outlined in the operation manual.

Advantages of Choosing a Crawler Pan Type Mixing Pump

- Enhanced Mobility: The crawler track system allows access to difficult-to-reach areas, eliminating the need for separate concrete transport in challenging terrains.

- Increased Efficiency: Combining mixing and pumping functions in one unit streamlines the concrete placement process, saving time and labor costs.

- Reduced Labor Costs: Fewer personnel are required compared to traditional methods involving separate mixing and pumping equipment.

- Improved Concrete Quality: On-site mixing ensures fresh and consistent concrete quality.

- Versatility: Suitable for a wide range of concrete applications and project types.

- Cost-Effectiveness: Reduces the overall cost associated with concrete transportation and multiple equipment setups.

Crawler-Type Mixing Pumps Manufacturer

YG is renowned for high-quality construction machinery, tackling real-world challenges. Choosing YG’s Crawler Type Mixing Pump brings multiple benefits: tailored engineering for diverse job sites, a global sales network spanning over 30 countries, rapid delivery, comprehensive technical support via video guides and live assistance, and affordable factory-direct pricing. We also offer Small Trailer Concrete Pump、Small Concrete Mixer Pump、Mini Portable Pumping Machine, etc.

WhatsApp/WeChat/Phone: 86 138 3715 9132