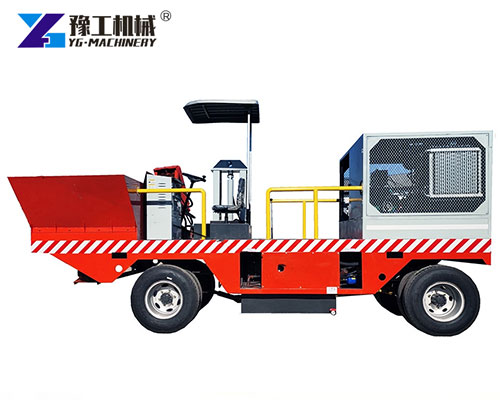

A Curb and Gutter Machine is an automatic machine used to cast concrete curbs and gutters in one pass. It pours and shapes concrete into a neat curb edge and a gutter beside it. This device saves time and gives a uniform finish on streets and parking areas.

Main parts include:

- Hopper to receive concrete mix.

- Molds for curb and gutter shapes.

- Vibration and compaction system.

- Walking or self-propelled chassis for movement.

This concrete curb machine is used on city roads, highways, parking lots, and residential streets.

WhatsApp/WeChat/Phone: 86 138 3715 9132

Product Parameters for Curb And Gutter Machine

| Model | YG-20 | YG-30 | |

| Length*Width*Height | 5200*2400*2800mm | 5200*4100*2900mm | |

| Unladen mass | About 7000kg | The deadweight is greater, the crawler grip is raised, the construction stability is improved, the climbing and sliding formwork flatness, and the slope is free from interference from external factors | |

| Construction scope | Width ≤ 2000mm (road shoulder, ditch), height ≤ 600mm (kerbstone, curbstone) | Width ≤ 2000mm Height ≤ 1100mm | |

| Hopper volume | 1m³ | 0.5m³ | |

| engine | Rated power | 65kw | Inline 4-cylinder turbocharged diesel engine (for high altitude areas, increased power output) |

| Operating voltage | AC380v | ||

| Startup form | Electric start | ||

| Rated speed | 1500rpm | ||

| Heat dissipation form | Water cooling | ||

| Molding method | High-frequency vibrator (suitable for plastic concrete) | Formed shoulders and side ditches have higher strength | |

| Attached vibration motor (suitable for dry, hard concrete) | Can be paved with curbstones and higher curbstone heights | ||

| Automatic leveling system (imported DLS, optional) | Leveling range ±40mm | Imported components, temperature compensation, overvoltage, and overcurrent protection | |

| Steering form | Dual automatic steering system (imported DLS, standard) | Imported components, temperature compensation, overvoltage, and overcurrent protection | |

| Manual steering wheel (hydraulic steering gear) | |||

| Minimum turning radius | 6800mm | ||

| Paving and transfer speed | 1m-10m/min | Frequency conversion speed regulation can achieve a wide range of stepless adjustment of paving and transfer speed | |

| Travel drive form | Full-time four-wheel drive | When the road slope is ≤5%, a fully loaded 15m3 tank truck can be used for construction, and the slipform machine connection construction can be realized. | |

| Screw feeder drive type | High torque hydraulic gerotor motor | Ensure the continuous feeding of concrete, the screw feeder will not be stuck by large stones, and the concrete will be mixed twice to improve the workability of the concrete. | |

If you are looking for a curb and gutter machine for sale, please leave a message.

Product Features: Gutter Paving Equipment Benefits

This curb paver has features that help crews finish work fast and well.

Main features:

- High Efficiency: It pours and forms curbs faster than manual work.

- Good Forming Quality: Molds produce straight, smooth edges.

- Labor Saving: Fewer workers are needed on site.

- Mold Flexibility: Change molds to get different curb shapes and gutter sizes.

- Vibration System: Ensures dense concrete and long-lasting curbs.

As a piece of gutter paving equipment, it reduces rework and gives consistent results across long runs.

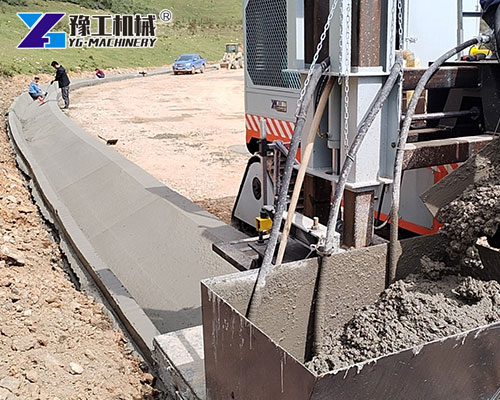

Construction Process: Automatic Curb Machine For Sale

The paving process is simple and repeatable. Follow these steps on the site:

- Pour concrete mix into the machine hopper.

- The machine pushes concrete through the mold.

- Vibration and tamping compact the concrete.

- The machine walks forward, forming a continuous curb and gutter.

- After curing, crews finish joints and remove mold if needed.

Using an automatic curb machine for sale speeds work and keeps the shape uniform. Operators set speed and mix flow, then the machine does the continuous forming.

Application Scenarios: Road Construction Curb Machine Uses

This machine fits many construction tasks:

- Highways and Expressways: Fast long-run curb forming.

- Municipal Roads: City street edges and gutters.

- Residential Areas: Neat curbs for sidewalks and driveways.

- Parking Lots: Defined edges and drainage gutters.

A road construction curb machine helps contractors meet tight schedules and keeps surface drainage consistent.

How To Choose The Right Curb And Gutter Machine

Select a model that matches your work and budget. Check these points:

- Project Scale: Small town jobs need a compact unit; big road projects need higher output.

- Mold Options: Ensure molds for your curb profile and gutter size are available.

- Power Type: Diesel gives mobility; electric suits enclosed sites.

- Maintenance Access: Choose modular designs for easy parts service.

- Spare Parts & Service: Verify local support and parts supply.

A clear choice reduces downtime and improves long-term cost control.

Why Choose YG Curb And Gutter Machine

YG offers practical curb pavers with full support for buyers.

YG advantages:

- Multiple models for small to large projects.

- Custom mold design to fit different standards.

- Export experience to Europe, the Middle East, and Asia.

- One-stop service from selection to shipping and on-site start-up.

YG machines aim to deliver accurate curb forming and low operating costs for contractors and municipalities.

WhatsApp/WeChat/Phone: 86 138 3715 9132